“Rain on a tin roofs’ been the good things in my life,” sang Aussie country crooner James Blundell in his 1993 album The Road – in which he reminisced about spending a romantic evening sheltering from a storm. And as romantic as they can be, for solar installers metal rooftops can cause headaches. The challenge being, how to securely install heavy solar modules in place without compromising the roof itself.

The most commonly used solution in the Australian market to date has been anodized aluminium rails onto which the modules can be fastened. Colorado-based S-5! is looking to change this, with its PVKIT fastening system doing away with the need for rails and facilitating quicker installations, the company claims.

“It seems like the industry has been a race to the bottom in prices,” says Dustin Haddock, Vice President of Research and Development at S-5!. “When we first started in Australia, it seemed like Australia was getting the modules other nations wouldn’t take and that started happening with the racking manufacturers – it went downhill from there.

“But then last year, I heard the Aussie solar market was realizing this wasn’t the right way, and companies were doing something about the race to the bottom,” Haddock continues. “The Smart Energy Council and the Solar Cutters were instrumental in that. We got involved; our motto is “the right way” and we saw there were others who very much agree with that philosophy and want to lift the industry back up to a level of measurable quality assurance. And with that we decided, ‘let’s not give up on solar in Australia’ and get involved with these bodies, face-to-face with EPCs, and those who really care.”

S-5! has supplied some high profile installations in the United States, including the striking Apple World HQ in Cupertino, California and the GooglePlex in Mountain View, California. It has mounted more than 2 GW of metal-roof solar arrays globally, including Costco stores in Australia.

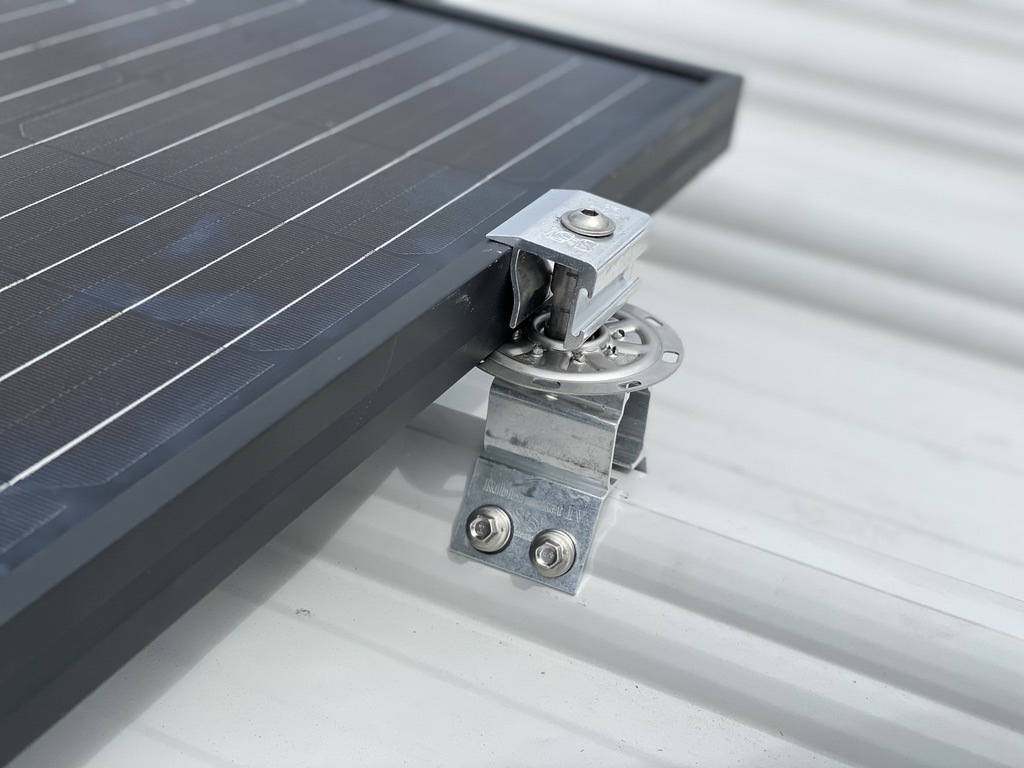

Photo: S-5!

S-5! clamps and brackets were first pioneered in 1992 by company Founder and CEO, Rob Haddock and can be attached directly to the metal roof and the solar module – circumventing the need to rails, and obviating the requisite to find structural battens below for attachment. This can make module layout more flexible. Along with solar PV, the clamps and brackets are used for attaching things like satellite dishes, HVAC systems, and walkways onto metal roofs.

Dustin Haddock is leading S-5!’s efforts in Australia and the region and has been working with installers in Auckland to familiarize them with the rail-free approach.

“We had some contractors [in New Zealand] who had never done direct attach,” says Dustin Haddock – Rob’s son, “and others who were very skilled in rail setups. Installers who had never used our products were getting 1 kW installed on the roof much more quickly: four modules installed with direct attach in the same time it took them to do just one module on the rails.”

“We just used our first S5 rail-less system on a 100kW commercial solar in Auckland,” reports Luke Nutting, the managing director of Lightforce Energy. “Once we got a hang of how the system worked, which was picked up incredibly quickly by the whole team, we were installing one panel every 80-120 seconds. This meant we could install rows of 17 panels in around 21 minutes.”

The question of cost

Haddock explains the S-5! clamps are competitive with a rail-based system on cost – particularly for larger arrays. In residential rooftops, the inclination of the roof can increase the labor cost over flat roofs. However it also brings into play the weight advantage S-5! clamps have over racks, which can come in at an 80% reduction, the company claims.

“If it is a commercial job and in some cases, depending on layout, we are more affordable or right on par,” says Haddock. “On residential buildings, our system may end up costing more when looking at part costs alone – particularly for a steep slope. But for a bigger job, our clamps are really competitive – part costs are the same or lower; however, there are logistics and labor savings.

Photo: S-5!

“There are a lot of complications that come with a rail. An S-5! mounting system consists of only three components, whereas a rail mounted system consists of up to 10 components. With our system, very little staging needs to be done: you just start dropping modules in, and that is why we have record speeds. The labor and freight savings are huge.”

Haddock says that the S-5! mountings result in a weight of 1.3-1.7kg/kWp compared with 8-10kg/kWp for a railed mounting structure. He adds that arrays using the S-5! Systems distribute load more evently across the roof. Storing and transporting the rails can also be cumbersome. With S-5! on the typical residential job of 6-8 kWp, all mounting goods can be taken up the ladder in a bucket along with all tools needed for the install.

At present, the PVKIT is designed to work specifically with framed modules, although S-5! Reports that it has a frameless clamping system under development.

In terms of dispersing heat, important to keep module operating temperatures on the roof down, Haddock says that the clamps fasten the modules planar but offset to the roof. However, with a trapezoidal roof profile, corry or Kliplok the modules sit 100mm above the surface, allowing for sufficient airflow to maximize module output. “And, it also helps with wire management and reaching under the module,” adds Haddock.

S-5! reports that historically it has worked very closely with U.S.-based module maker SunPower but has established similar partnerships to co-qualify its products with TrinaSolar, Q-Cells and JinkoSolar, among others. Its current Australian distributors are Rapid System Solutions and Mak Fastener Specialists.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.