The need for inexpensive, fast, reliable chemistries and technologies for storing renewable energy is breaking the lithium-ion mould. Get used to the terms “beyond-LIBs”, “strain engineering” and “hydrogen-bonding metal hydrides”, and enter the labs of Professor Guoxiu Wang at the University of Technology Sydney and Professor Kondo-Francois Aguey-Zinsou at the University of New South Wales.

Professor Aguey-Zinsou’s new technology could provide energy at 2 cents per kilowatt hour and is expected to be patented within weeks.

At UNSW’s Materials Energy Research Laboratory in nanoscale (MERlin), Aguey-Zinsou has been working on storing hydrogen by bonding it with solid materials, such as magnesium nanoparticles.

Image: UNSW MERlin

It’s a safer approach than storing hydrogen in gas or liquid form; and many hydrides act like a sponge for hydrogen, absorbing it to the high volumetric capacity required for efficient storage of energy.

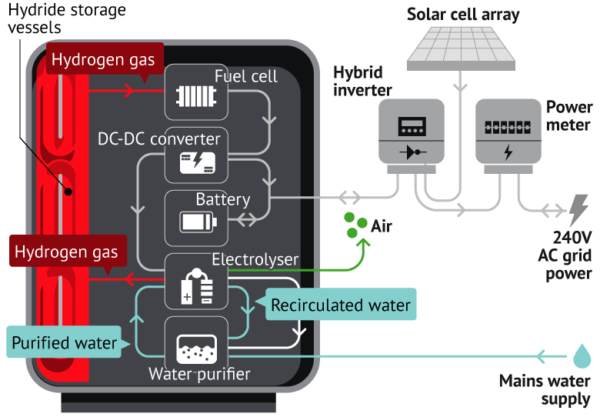

Aguey-Zinsou, who has spent 20 years investigating hydrogen-bonding metal hydrides, has applied his breakthrough technology — a hydrogen-absorbing metal alloy that includes titanium — to an energy-storage system designed for residential and commercial use, which could be commercialised in early 2021.

“It’s a game changer in how we use electricity,” the Professor told the Sydney Morning Herald, likening the development to “the internet revolution”, and emphasising the safety of the chemistry involved — “It’s not flammable,” he said.

The resulting residential battery system, engineered at UNSW’s Hydrogen Energy Research Centre, which has received $10 million in funding from Providence Asset Group, is expected to have a 60 kWh capacity and occupy the space of a mini-fridge with a height of about 130 cm.

Image: UNSW Hydrogen Energy Research Centre

A co-founder of Providence, Alan Yu, has said the batteries will be manufactured in Australia and will be branded LAVO.

He also hopes to scale the system by containerising numerous battery units to be used at scale on projects such as the community 4.5 MW Manilla Solar Farm near Tamworth, developed by Providence Asset Group with the help of $3.5 million in funding from the NSW Government Regional Community Energy Fund.

UTS taps into abundant metals for low-cost large-scale storage

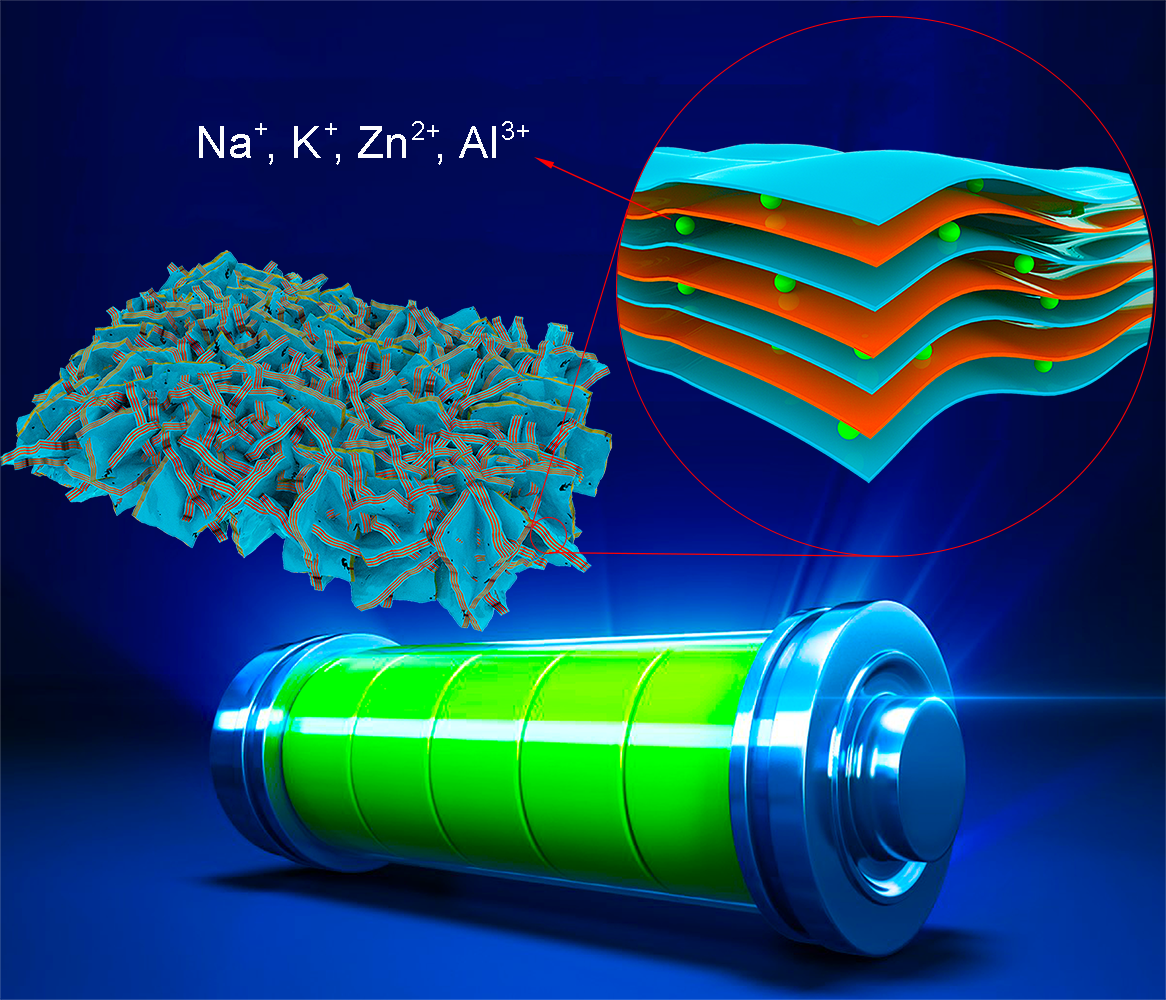

At UTS, the focus has been on developing large-scale, high-density energy storage technologies using abundant metallic elements such as sodium, potassium, zinc and aluminium.

Dubbed beyond-LIBs (beyond-lithium ion batteries), batteries based on sodium-ion or aluminium-ion chemistries have been hampered by a lack of suitable electrode materials.

On Friday, a group led by Professor Guoxiu Wang at the UTS Centre for Clean Energy Technology, working in collaboration with Professor Tkayoshi Sasaki from the National Institute for Materials Science in Japan, released a paper in the journal Nature Communications, documenting their work on Strain engineering of two-dimensional multilayered heterostructures for beyond-lithium-based rechargeable batteries.

Strain engineering describes a process of tuning a material’s properties by altering its mechanical or structural attributes.

In this case, the researchers have applied strain engineering to a two-dimensional graphene nanomaterial to produce a new type of zero-strain cathode, “for reversible intercalation … of beyond-Li+ions”, said Professor Wang.

Intercalation is a term used in chemistry to describe the reversible inclusion or insertion of a molecule (or ion) into materials with layered structures. An intercalated lithium-ion battery has sheets or films of material separating layers of lithium, which allows positively charged lithium ions (cations) to shuttle between the anode and cathode electrodes.

“When applied as cathodes in K+-ion batteries, we achieved a high specific capacity of 160mA h g-1 and a large energy density of ~570 W h kg-1,”said Wang, which represents the best reported performance to date, and could also be applied as cathodes for high-performance sodium (Na+), zinc (Zn2+) and aluminium (Al3+-ion) batteries.

Such elements are far more abundant in the earth’s crust than lithium; and zero-strain electrode materials are promising for their excellent long-cycling performance.

The researchers report that their work “heralds a promising strategy to utilise strain engineering of 2D materials for advanced energy-storage materials”.

Watch this door to the future.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

While this approach will store electricity it is far more complex than a LIB. Also the energy losses in this system are likely to be in the order of 50%. i.e. 100Mw in 50Mw out. Electrolyzers and fuel cells are only about 80% efficient. On the other hand energy losses in LIB are in the order of 20%. That is an input of 100Mw will deliver 80Mw

Awesome! Thank you!!!