It’s not often that solar installers are consulted on their requirements of the components they work with every day, but solar mounting manufacturer Clenergy has launched an entirely Australian made 4400 mm finished rail for solar modules, which had the input of a community of solar professionals dedicated to promoting quality in the industry and interested in a more local supply chain of equipment. A portion of sales of the Cutter Rail, a mounting engineered to accommodate the larger, higher-output solar panels now favoured by the market, will also be funnelled back into fostering the Solar Cutters group that contributed to its specifications.

Clenergy is an Australian company that specialises in the development, manufacturing and marketing of solar-mounting gear. Solar Cutters is a 2,500-member industry group, anchored in a Facebook page that provides rapid, experienced member feedback and assistance on curly problems encountered while installing solar panels on rooftops throughout Australia.

Some dedicated industry brands and manufacturers are welcomed on Solar Cutters, which derives its name from The Simpsons’ references to Stonecutters, and seeks to provide a sales-pitch-free zone for installers. “We only allow in participants who are going to demonstrate value,” Solar Cutters Co-founder and Director Jack “Longy” Long tells pv magazine. “If they are a manufacturer they have to be able to provide technical support within a reasonable timeframe.”

Clenergy’s National Channel Manager, Sean Guzzi, fits the criteria. Guzzi is second-generation solar — his father Mario Guzzi founded Clenergy as an inverter manufacturer, with partner Daniel Hong, in 2007. Eventually solar mounting gear became the focus of the business, but competitive factors meant the company has always manufactured its components in China.

Long and Guzzi became friends through Solar Cutters, each recognising the other’s commitment to quality: “This is a great industry,” says Long. “We’re super passionate about about high-quality installations.”

They hatched a plan that would start to realise some of their individual and joint ambitions: Guzzi believed the cost of manufacture of quality aluminium products in Australia was reaching parity with product made in China, and wanted to start making some of the company’s components on home ground; Long was also motivated to support Australian manufacture and wanted to hold more networking and training events for Solar Cutters, but needed funding that came without strings attached.

For the people, by the people

“I was using the Solar Cutters Facebook group for feedback about the rail,” the design of which needed to consider current and emerging market trends, says Guzzi. “You know, panels are getting longer and wider every day, which creates more of an uplifting force if the wind gets underneath it,” he tells pv magazine.

Clenergy mounting gear is engineered to withstand Australian conditions, in particular the high winds of cyclone zones, and exposed coastal and outback areas. The company’s generic mounting products are sold with “an engineering certificate that takes into account the many different factors you might come across in a residential installation and some smaller scale commercial installations”, says Guzzi — factors such as roof height and pitch, the surrounding terrain (exposed or built up), the size of solar panels … Some 75% of installations are well served by Clenergy’s generic products, while tougher installs are referred to the company’s engineering team for bespoke designs.

In finalising the new Australian-made generic rail, Guzzi turned to the Solar Cutter community for feedback, and among their responses was the decision arrived at by a poll on the Solar Cutters’ Facebook page, to extend the standard rail length from 4.2 metres to 4.4 metres.

“Basically, installers still wanted to be able to get four of the wider panels on a length of rail,” says Guzzi.

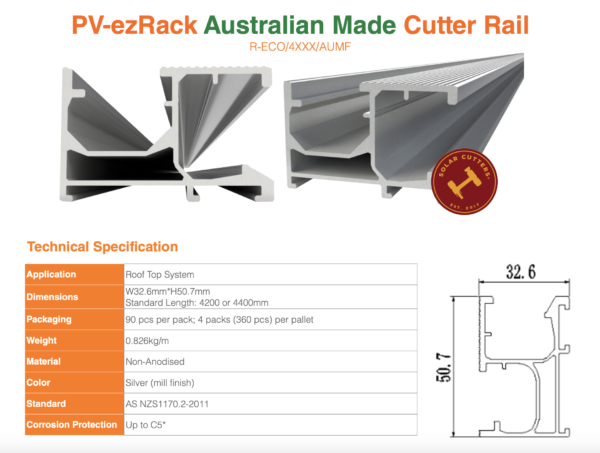

The Cutter Rail is manufactured at the Queensland and Western Australian plants of Capral — an ASX-listed company that employs more than 900 people — from non-anodised aluminium, to Australian and New Zealand standards AS NZS1170.2-2011.

“There are still cheaper products coming in from overseas,” says Guzzi, but he says sales are already supporting the quality of the Cutter Rail.

Long told pv magazine, “There was a big push in the industry and on social media towards sourcing locally manufactured products, and that’s something we at Solar Cutters can really get behind — especially when it comes to racking. A lot of people regard it as the cheapest component of an install, but it’s the most critical component of a solar installation for resi because it holds the load to the roof!”

He adds, “The fact that we had a bit of fun with it,” is another selling point. “Everyone loves the Monorail episode of The Simpsons, where Lyle Lanley keeps saying ‘Monorail, monorail, monorail’. Sean and I were saying, ‘Imagine if it was Cutter Rail, Cutter Rail, Cutter Rail’”.

Proceeds from sales of the rail are already flowing to support a series of installer nights, which will be scheduled when Covid-19 restrictions are further eased. “The content of the events will be voted for by members,” says Long, who is delighted that he and Guzzi found “a way to give back to the industry that doesn’t affect the installer’s hip pocket.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.