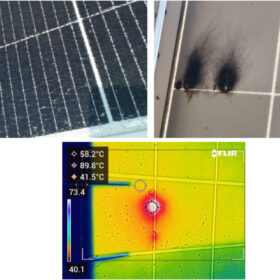

Study shows reducing number of solar modules per string reduces hotspots risk

Scientists in Indonesia have investigated early operational defects in a 24.9 MW solar PV system in Sumatra and have identified hotspot formation as the dominant defect. They also detected 282 cases of glass cracking, 350 cases of junction box failures and shading effects linked to module defects.

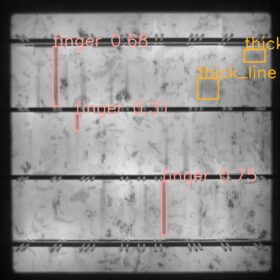

New deep learning tech uses electroluminescence images to identify defective PV cells

The novel method uses the YOLOv8 framework, integrating an attention mechanism and a transformer model. It was tested on a dataset of 4,500 electroluminescence images against several other models and its results were up to 17.2% more accurate.

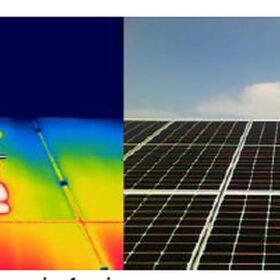

Shining a light on module quality

With solar panel prices tumbling, project developers will need to be vigilant about quality. Comprehensive product testing could be a vital safeguard as PV manufacturers struggle to retain their margins, according to Everoze’s Martin Laing and Gauthier Dambrine.

Weather risk up, margins down: solutions to future-proofing big solar

Extreme weather is a growing risk to solar farms. Future-proofing through advanced technologies, leveraging data from novel sources, and by building both collaboration and acceptance of risk is vital, but rarely achieved today for a number of reasons. Insurers, lenders, developers, contractors and manufacturers come together here to discuss solutions to the intractable problem of weather risk.

Around 6,000 recalled LG home batteries have still not been located

Around 6,000 batteries involved in the years-long LG battery recall have not yet been located, the ACCC has said. To date, there have been at least nine reported incidents involving the batteries, including one personal injury and one house “completely destroyed.”

Weekend read: BESS lessons learned

Taking a rigorous approach to inspection is crucial across the energy storage supply chain. Chi Zhang and George Touloupas, of Clean Energy Associates, explore common manufacturing defects in battery energy storage systems (BESS) and how quality-assurance regimes can detect them.

Why True Zero carbon is the right side of history

It is time to call out the problems of Net Zero, Enosi’s Grant McDowell argues. To reach a fully renewable grid, companies and institutions instead must embrace what he calls True Zero.

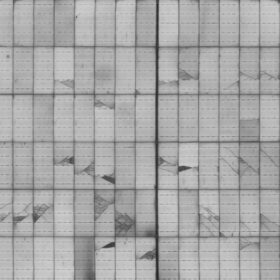

New survey shows ‘massive’ increase in PV module microcracks

A new study from Clean Energy Associates (CEA) shows that 83% of sites tested as part of a global survey had line cracks, 78% had a soldering anomaly and 76% had complex cracks. The survey involved visual inspections combined with electroluminescence testing across 148 sites in 16 countries.

Quinbrook introduces energy tracing into portfolio as Australia hesitates on granular certificate scheme

Renewable energy investor and developer Quinbrook has launched software to allow customers to trace both the source and carbon-intensity of their electricity in real-time. The energy-tracing platform comes at an important moment, just as Australia’s government is deciding whether to include time-stamped and granular source information in its formal certificate schemes.

Combination of half-cut, bifacial solar cell designs may contribute to hotspot formation

Scientists in Spain tested PV modules under partial shading conditions, aiming to better understand the formation of performance-damaging hotspots. The study reveals a potential issue particularly affecting half-cell and bifacial modules, which may cause accelerated performance loss and is not covered by current testing/certification standards.