Heterojunction solar cells have the potential to provide the next big efficiency leap in solar output, but their need for low processing temperatures means they require very high quality, expensive n-type silicon wafers as input to production. In recent years, significant research has been devoted to eliminating defects in low-cost p-type silicon, so that it could start to match and perhaps surpass the cost-to-efficiency ratios of the long-time hero of the photovoltaic industry — PERC technology.

A new review of research into defect engineering in p-type wafers could reroute the path to a silicon heterojunction (SHJ) takeover.

Although Australia has seen record uptake of rooftop solar, the upfront cost of a solar system remains a barrier to more widespread slathering of solar on buildings both here and overseas. Engineering more efficient solar cells would mean households need fewer solar panels, with attendant lower installation costs, to meet their electricity needs, and homes with small roof expanses could get more bang per solar panel.

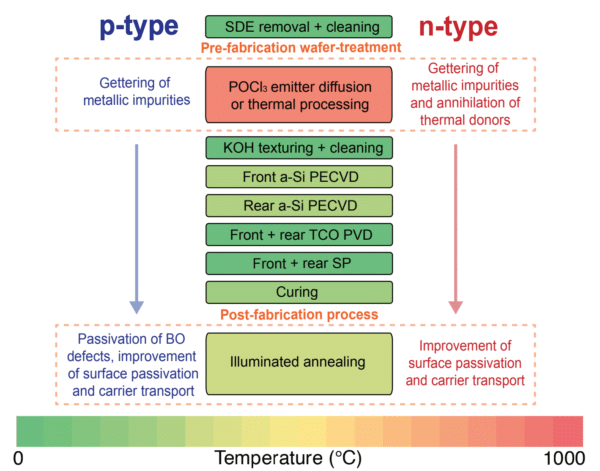

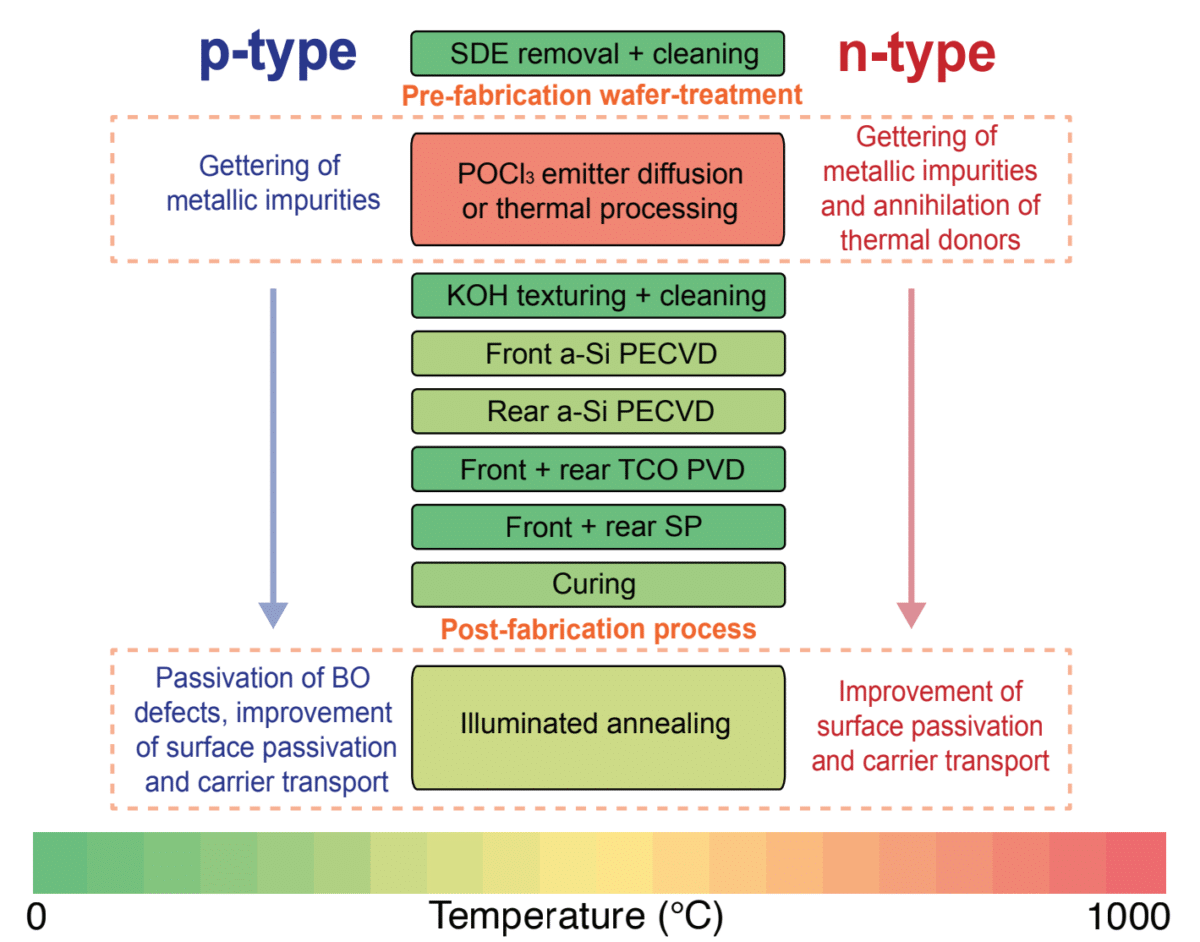

Recent research into raising the performance of cheap p-type silicon wafers, using processes such as gettering of wafers before they enter production and annealing at the end of the cell-production process, has shown great promise, but says Dr Matthew Wright, lead author of the review paper, it also reveals solid research evidence that “the same techniques can be applied to n-type wafers to improve the performance of those cells”.

Wright is an Australian Renewable Energy Agency (ARENA) post-doctoral fellow in the School of Photovoltaic and Renewable Engineering (SPREE) at the University of New South Wales, working on the final stages of the four-year Hydrogenated and Hybrid-Heterojunction P-type Silicon Solar Cells project, led by UNSW’s Associate Professor Brett Hallam.

He and the new review paper’s second author, PhD student Bruno Vicari Stefani, talked to pv magazine Australia about the twist to their review which is based on Vicari Stefani’s PhD on improving p-type silicon, plus the work of other scientists at UNSW including Dr Anastasia Soeriyadi; the Australian National University (ANU); Arizona State University; and also the results gleaned from manufacturers who are already incorporating some of these methods into production.

SHJ has a foot in the door

Globally, a number of manufacturers are producing SHJ solar cells, including Hevel Solar. The Russian manufacturer produces 340 MW of SHJ cells annually, and claims an efficiency of 24.1%.

Wright says that Chinese Tongwei Solar, “probably the biggest manufacturer of solar cells in the world has an unbelievable expected PERC capacity of 55 GW by the end of this year, but they also have one gigawatt of expected capacity for silicon heterojunction as well”, which shows, he says, that “they’re investing in this technology as a potential next phase”.

The thinking has been that if manufacturers could substitute cheap p-type silicon for the current standard use of n-type in SHJ production, while not sacrificing too much of the p-type efficiency, the tide of production and further development might swing towards SHJ, to give greater cost-to-efficiency benefits than PERC can now achieve.

PERC (Passivated Emitter and Rear Cell) technology was invented by Scientia Professor Martin Green of UNSW in the early 1980s. Speaking at this year’s Smart Energy Summit, Green said that in 2021, around 95% of global silicon solar cell production will use p-monocrystalline PERC, and that the cost of energy produced by PERC-based solar modules will descend to 10 cents per watt by 2023.

The PERC manufacturing process passivates as it goes

PERC already uses the cheaper p-type silicon because, says Wright, the very high temperatures (around 700 degrees Celsius) used to form the electric field in the solar cell, and to solidify the metal contact points which are screen printed onto the cell as a metal paste, also have a positive — or passivating — effect on the quality of the silicon.

In SHJ cells, however, the material applied to the surface of the cells, which delivers their high-voltage efficiencies, is sensitive to heat, and cannot be subjected to greater than 200 degrees Celsius, “so all those kind of defect-engineering approaches that are inherent in the PERC cell fabrication, and which improve the quality of the silicon are out the window”, says Wright.

“The whole point of our review,” he adds, “and the whole point of Bruno’s thesis, is to get around that problem by treating the wafer before it goes into making the cell, and doing some kind of annealing process after the cell is finished.”

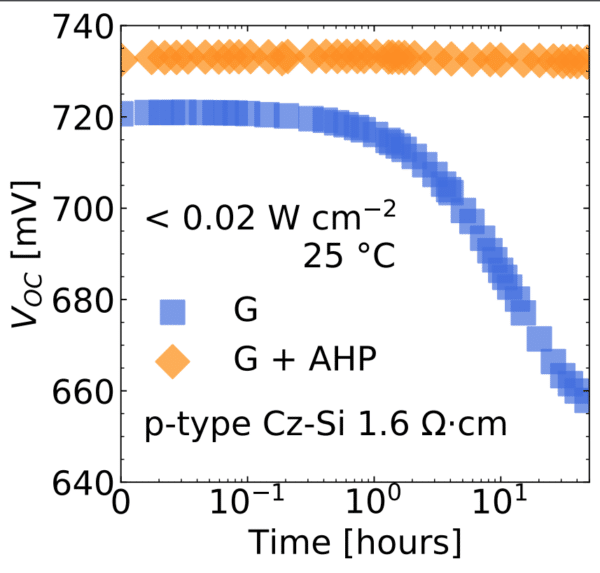

In one example, researchers at UNSW are using high-intensity laser light, a process called illuminated annealing, to change structures within the cells as a final stage of production.

Image: UNSW

The winning cost-to-efficiency ratio?

The cost of such processes is outlined in the review paper — Progress with Defect Engineering in Silicon Heterojunction Solar Cells — which has been released in the 60th-anniversary edition of the journal PSS Rapid Research Letters.

Wright explains that if processes start to incorporate cheaper p-type wafers, their efficiency will be lower. How much lower can that efficiency be and still deliver a cost benefit.

“If we go from n-type to p-type, and we save 10% in the cost of the wafers, but the cell efficiency is only 20% compared to 23%, then we wouldn’t be winning in the long run,” he says.

UNSW costing analysis found the efficiency of p-type silicon would need to be within about 0.5%abs to 0.4%abs compared with n-type.

So if n-type efficiency is 23%, the target for p-type efficiency would be 22.6%. If n-type is 24%, p-type would need to hit 23.6% for costs to break even. If p-type efficiencies could be pushed a little more, says Wright, “we’d be making cost savings”.

Making n-type work harder

However, the real take-home message from the review paper, says Wright, is that “We’ve spent three to four years trying to develop techniques to increase the efficiency of cheaper low-quality wafers, but now we’re realising these techniques have a positive impact on n-type wafers as well.”

Which, he concludes, begs the question, “Do we need to rethink the standard industrial approach to silicon heterojunction solar cells?”

Improving the efficiency of more expensive n-type cells using some of these processes, may be the low-hanging fruit in terms of possible cost reductions for SHJ technologies.

Image: UNSW

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.