Australian governments and industry have embraced the potential of green hydrogen with 38 GW (AC) of assets already announced but new analysis from independent consultancy Rystad Energy has warned capital expenditure costs need to slashed by 75% for it to be cost competitive with fossil-fuel alternatives.

The Australian Government has committed to green hydrogen – generated by electrolysis powered by solar PV and wind energy – as a fuel for the future, formally recognising it as a ‘priority technology’ in the Technology Investment Roadmap announced late last year.

The government, which reaffirmed its commitment to the technology at the recent G7 Plus Summit in England by signing new partnerships with both Germany and Japan to support hydrogen initiatives, has set an economic ‘stretch goal’ to produce green hydrogen for $2 per kilogram.

At that price green hydrogen is expected to be cost competitive in applications such as producing ammonia as a transport fuel and for firming electricity and will help Australia capture a significant share of the growing global export demand for the renewable fuel.

Rystad Energy senior analyst David Dixon has however declared reaching the $2p/kg target shapes as a real challenge, saying detailed examination of cost factors in Australia showed green hydrogen would struggle in the foreseeable future to be cost competitive with gas produced using fossil fuels.

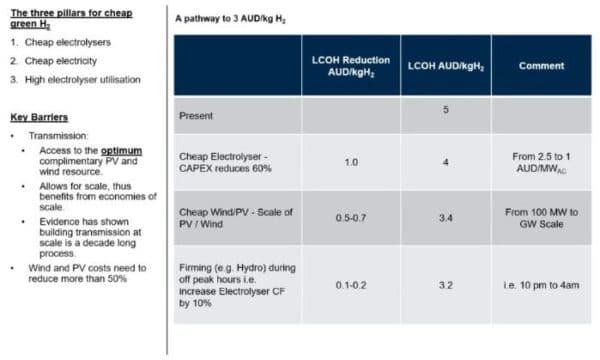

“At the present time we have a cost, best case scenario, of about $5 per kilogram of hydrogen,” Dixon said. “We see $3 as foreseeable but $2 becomes extremely challenging.

“A lot needs to go right in order for this to work.”

Image: Rystad

Dixon last week released details of a year-long investigation into the levelized cost of hydrogen (LCOH) in Australia.

The analysis, based on a 100 MWh electrolyser facility powered by current solar PV and wind technology, included more than 2,400 simulations for every state investigated and took into account the AC capacity of the solar and wind assets, and the capex and opex of all elements in the equation.

The investigation identified electricity costs, the electrolyser capex and the opex of the electrolyser as the three key components of the LCOH and determined the costs of all facets would need to come down to reach the government’s stretch goal.

“Our numbers suggest you need to reduce the capex of the total system, that is the electrolyser, the PV and the wind by 75% as well as improve the capacity factor in order to get to the government target of $2p/kg of hydrogen,” he said.

Dixon said the required cost decline is foreseeable for hydrogen electrolysers as they start to get built at scale but warned achieving similar reductions for PV and wind it is going to be a real challenge with electricity makes up the bulk of the LCOH.

“The wind and PV costs have to come down by over 50% and this is a very, very big challenge in a mature industry,” he said. “And in the short term, we’re actually predicting costs of key equipment to go up as commodity prices rise, not go down, so $3 is foreseeable and $2 is very, very challenging.”

Image: Rystad

The report shows gains in electrolyser efficiency, including firming during periods of low demand on the grid, would also be critical in reducing costs but Dixon said even with the foreseeable reductions, the LCOH would still be above the $2p/kg target.

“If the capex of electrolysers reduces 60%, we can knock off a $1, if we build utility PV and wind at a scale and thus benefit from the economies of scale, you knock off about 50 cents and if you firm between off-peak hours you can reduce that further but it still only takes you to $3p/kg,” he said.

“There has to be a shift or subsidy even at scale in order to displace the existing production of hydrogen from steam methane reforming.”

While costs remain a hurdle for the industry, the Australian government remains committed to hydrogen, signing a new accord with Germany which will see the two nations invest in a new series of initiatives designed to accelerate the development of a hydrogen industry.

Included in the initiatives is the establishment of the German-Australia Hydrogen Innovation and Technology Incubator (HyGATE) with both countries to commit up to $50 million to support pilot and research projects along the hydrogen supply chain.

The new accord will also see the two countries exploring options to facilitate the trade of hydrogen and its derivatives produced from renewables from Australia to Germany.

Australia also announced a new agreement with Japan to jointly support initiatives that will help drive transitions to net zero emissions with a focus on clean technology such as hydrogen.

Image: Scott Morrison/Facebook

Prime Minister Scott Morrison said international collaboration focused on technological innovation is key to getting new energy technologies like hydrogen to commercial parity.

“Our ambition is to produce the cheapest clean hydrogen in the world, which will transform transport, mining, resources and manufacturing at home and overseas,” he said.

“We have a mix of all the key ingredients needed to be a major global player in a thriving global clean hydrogen industry – abundant land and energy resources coupled with an excellent track record and reputation as reliable energy partner.

“We have set the goal of producing hydrogen at less than $2 a kilogram – ‘H2 under 2’, the price at which hydrogen becomes competitive with higher-emitting alternatives.”

The government believes the green hydrogen industry could add $11 billion to the economy by 2050 and potentially as much as $26 billion, depending on how quickly global demand grows.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

It would be nice if the cost of green H2 can be lower than the cost of dirty H2 from methane or brown coal BUT the target is to manufacture and supply Green H2. The competition from dirty H2 can be removed by legislation. The real target of clean H2 is to be cheaper than Batteries and other storage methods.

Or is there an hidden intent to sell dirty H2 for years while “developing” the clean product?

Our government and the opposition should make it clear now that there is to be no leniency while H2 manufacturers pretend to experiment with ways to produce cheap clean H2. The opposition in particular should announce that they will not honour any agreements between this government and manufacturers that results in the production of dirty H2 in any quantity. Take away any sovereign risk” and replace it with absolute “sovereign certainty”

I agree. Electricity will always be energetically more economical than hydrogen. Huge amounts of money are being thrown at hydrogen because the fossil fuel industry wants to retain control over the supply of energy. CSS has proven largely unsuccessful but continues to be funded. Hydrogen from fossil fuels is the basic plan. Exporting hydrogen is crazy because of the high energy inputs required to compress or liquify it. Export green ammonia/urea, green steel and aluminum smelted with renewable electricity.