New South Wales company Hysata is on track to commercialise the world’s most efficient electrolyser, capable of producing green hydrogen for less than $2 per kilogram by the ‘mid 2020s,’ it says. Moreover, the company believes it can reach gigawatt scale hydrogen production within a similar timeframe, saying its design is simple and mass manufacturable today.

The company was born out of an electrolysis breakthrough made at the University of Wollongong, south of Sydney, around three years ago. There researchers led by Professor Gerry Swiegers discovered hydrogen could be produced far more efficiently using capillary-fed electrolysis.

This was verified in a paper published today in peer-reviewed scientific journal Nature, which found the capillary-fed electrolyser could produce green hydrogen from water at 98% cell energy efficiency.

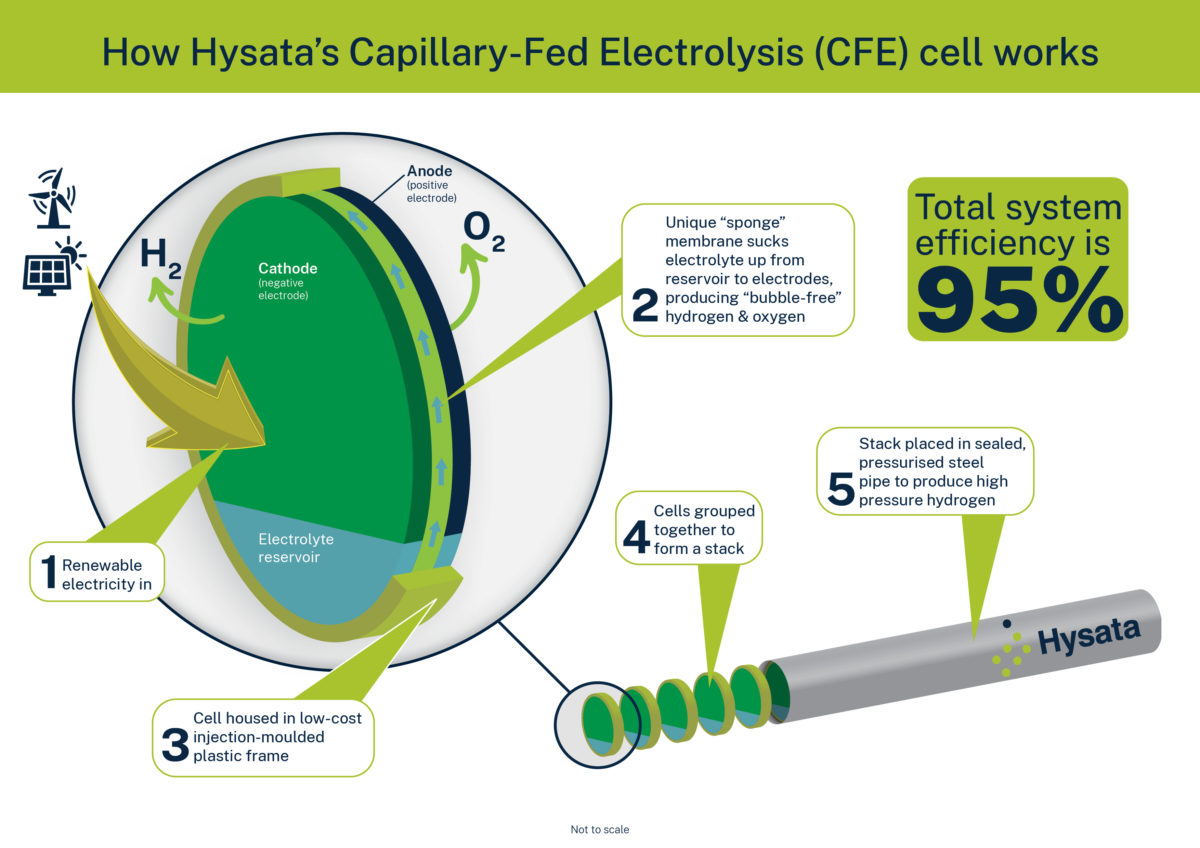

Image: Hysata

The Hysata electrolyser consumes 40.4 kWh of energy for every kilogram of hydrogen it produces. The Nature paper noted commercial electrolysis cells tend to use around 47.5 kWh/kg, though Hysata CEO Paul Barrett claimed it was closer to 52.5kWh/kg. This equates to around 75% system-level efficiency, whereas the Hysata system claims a total efficiency of 95%.

This 20% efficiency boost has enabled the massive cost reduction Hysata says it’s only a few years away from making a reality. “You really collapse the project economics through that efficiency lever,” Barrett told pv magazine Australia. “And compounding on top of that, [Hysata has] a simplified system which really reduces the cost quite substantially.”

Barrett didn’t want to commit publicly to price of the Hysata electrolyser, but said the company is in conversation with around 30 “name brand companies” needing green hydrogen who are “thrilled” about the economics.

“Our technology will enable hydrogen production of below US$1.50/kg per kilogram by the mid-2020s, meeting Australian and global cost targets much earlier than generally expected,” Barrett said.

Commercialisation timeline

Barrett said the company is busy building its pilot line of electrolysers in house near Wollongong now. “We’re building a huge test capacity like today.” He is hoping to begin testing them in parallel within the next few months, with plans to ramp up the pilot line in 2023.

Hysata

From pilot scale, the company wants to jump directly into gigafactories. To enable this, Hysata will grow its team of 20 engineers significantly this year.

“We planning to have systems in the field by 2025,” Barrett said.

“I’ve got plates working today at the efficiency and performance that we’ve got on that [Nature] paper, and our next thing is to basically string lots of those together, not unlike the way you’d string multiple solar modules together. We’ll connect them in series and that becomes our stack.”

Australia-made

The company “certainly” plans to keep its manufacturing in Australia, Barrett said, possibly remaining in Wollongong – which is right next door to the proposed Port Kembla hydrogen hub.

“This can be an era defining company for Australia,” the CEO said, noting that Australia imports the vast majority of its renewable equipment today, like solar panels and wind turbines. “There’s a real opportunity to build sovereign manufacturing capacity here in Australia and export it to the world.”

Image: Wollongong City Council

This very much aligns with Matt Kean’s plan, the state’s environment and energy minister as well as treasurer. In February he announced $250 million in funding to boost locally manufactured renewable energy content and a further $300 million to build a renewable powered manufacturing base including renewable hydrogen.

‘Need breed of electrolysis’

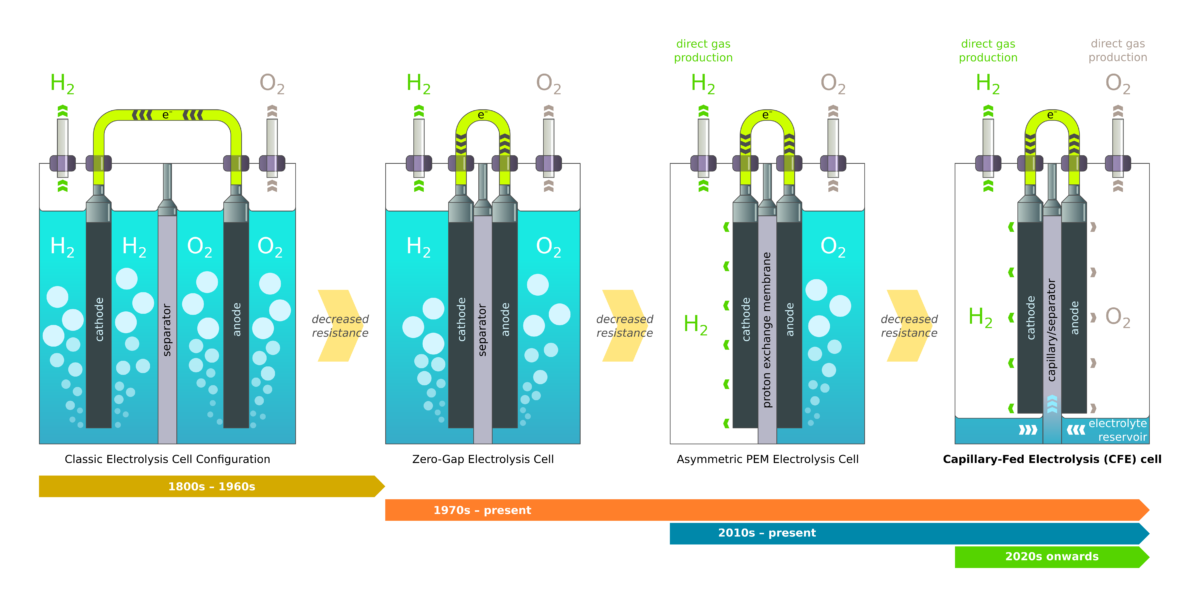

The company is the “first in the world” to commercialise a capillary-fed electrolyser, according to Barrett. To date, he says electrolyser technology has been “too inefficient and too complex” to make green hydrogen attractive. Hindering efficiency in electrolyser cells is resistance, which has typically come from bubbles which are non-conducting and mask electrodes.

“[The research team at Wollongong university] basically looked at that problem with a blank sheet of paper and really tried to understand where all the resistance is inside the cell.” That exercise led to the invention of capillary-fed electrolysis which eliminates these bubbles and boosts efficiency.

This leads to a “double whammy benefit on the economics,” Barrett says, because hydrogen projects would need less renewables to get the same hydrogen output, saving on capital outlays, while also only needing to purchase a smaller electrolyser.

Electrolsyer details

The company’s electrolyser is fives times smaller than a traditional alkaline electrolyser, Barrett says, and contains 20x less liquid. It fits inside a 6 metre shipping container and is forkliftable for easy transportation, he added. “So we’ve got a drastically simplified balance of plan.”

Hysata’s electrolyser cell frame is made using a scalable, low cost and mass manufacturing technique – making the product nimble so it can get to market as quick as possible.

“We’re one of the few, if not the only, electrolyser from time zero to be mass manufacturable,” Barrett said.

Image: Hysata

Hit the ground running

Hysata, a startup, only officially launched in June last year. It kicked off with $5 million in seed funding from the UK-based IP Group, with $750,000 from the government-owned Clean Energy Finance Corporation (CEFC).

Professor Swieger, who led the University of Wollongong ARC Centre of Excellence for Electromaterials Science research, has since become Hysata’s Chief Technology Officer.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

12 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.