Western Australian company Neometals is close to finalising a partnership with one of the world’s most renowned automotive brands, Germany’s Mercedes-Benz. Mercedes has said it plans to partner with Primobius for the design and construction of its future battery recycling plant in Kuppenheim, marking Mercedes’ first move into battery recycling.

Mercedes is looking to go all electric by 2030, though lithium and other battery material prices have soared recently – making the 2,500 tonne a year recycling plant an even more urgent proposition.

“The recovered materials will be fed back into the recycling loop to produce more than 50,000 battery modules for new Mercedes-EQ models,” Mercedes said.

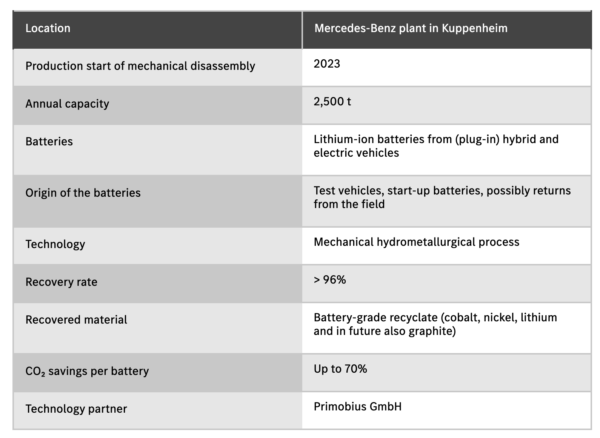

The plant is to be constructed in two stages. “Initially, a plant for mechanical dismantling will be constructed by 2023,” the company said. The second stage, which it noted is subject to “promising” discussions with the public sector, would involve constructing facilities to employ Primobius’ hydrometallurgical battery processing technology.

Mercedes-Benz

“This means that in the future, Kuppenheim could cover all the stages from dismantling to module level, shredding and drying and subsequent processing of battery-grade material flows,” Mercedes said. The plant will make the company “more independent of raw material supplies in the future,” it added.

Mercedes said it is investing “a double-digit million euro amount” in both research and development and to construct the CO₂-neutral pilot plant in Kuppenheim. The project has also received the prospect of funding under the Battery Innovation Support Program of the German Federal Ministry of Economics and Climate Protection.

Unlike the carmaker though, Neometals pointed out that legally binding agreements are yet to be signed between Primobius and Mercedes, though its managing director, Chris Reed, said he expects them to be finalised “in the near future.”

He added that he’s “proud” one of the “greatest names in the automobile industry” had made public its partnership plans with his company.

Primobius (Neometals & SMS Group)

Primobius’ technology

In the second half on 2021, Primobius, half owned by Neometals with the other half belonging to German SMS Group, finished commissioning its battery recycling demonstration plant in Hichenbach, Germany.

Primobius uses solvent extraction as its primary recovery tool, a process Reed says was actually invented in the Australian mining hub of Mount Isa in central Queensland. “It’s applying existing Australian technology into a new field,” Reed told pv magazine Australia last November.

What distinguishes Primobius’ process is its waste-free status. “We’ve developed flowsheets that not only try to maximise our recoveries, but that are actually green,” Reed said. “There’s no emission of any water, any waste water – we’ll be reusing that, and our tails are a fertiliser product and our CO2 footprint is very low.”

Mercedes plan

Given Mercedes is anticipating the recycling plant itself will be carbon neutral, Primobius’ process would be undeniably attractive to the carmaker. It has founded the subsidiary Licular GmbH especially for its foray into lithium-ion battery recycling.

ASX

Based on the findings of the Kuppenheim pilot plant, Mercedes said production volumes could be scaled up “in the medium to long term.”

The batteries the plant will recycle will originate from test vehicles, start-up batteries, possibly returns from the field, the company said. The materials it plans to recover are cobalt, nickel, lithium and, in future, graphite.

Mercedes estimates the recycling facility will avoid up to 70% of the CO2 emissions per battery, an increasingly important measure in Europe where carbon intensity is being closely watched and soon to be priced.

Scientific support for the project will be provided by three research institutes: the Karlsruhe Institute of Technology and the Technical Universities of Clausthal and Berlin.

“With our new recycling plant at the Kuppenheim location, we are increasing the recycling rate to more than 96% while expanding our own expertise in the area of battery value creation,” Jörg Burzer, Member of the Board of Management of Mercedes-Benz Group AG, Production and Supply Chain Management, said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.