South Australian-based solar PV module maker Tindo Solar has published a video detailing the manufacturing process at its new factory at Mawson Lakes in Adelaide’s northern suburbs.

The new $11 million plant includes a production line that can produce panels featuring M10 cell technology and has allowed Tindo to expand its suite of solar modules, with the company recently launching a new 545 W large-format panel for utility-scale solar projects.

The newly commissioned factory has the capacity to produce up to 150 MW of solar panels per annum and is more than three times the size of the company’s previous manufacturing facility.

The release of the video comes after the International Energy International (IEA) earlier this month warned of a need to diversify the world’s solar PV supply chain and expand the production of solar modules, suggesting the sector’s heavy reliance on China has led to imbalances that pose risks to its future growth.

China is the world’s largest solar supplier, dominating not only panel manufacturing but the entire upstream supply chain with a special report from the agency showing the nation controls more than 80% of all the manufacturing stages of solar panels.

When announcing the report, IEA executive director Fatih Birol said China’s dominance of PV supply chains poses specific vulnerability and risks to the industry.

“We believe this level of concentration in any global supply chain would represent a significant vulnerability; solar PV is no exception,” he said. “It is a must, in my view, to diversify. Otherwise, we may see major challenges in the days, months and years ahead.”

These challenges have already resulted in delays in solar PV deliveries and higher prices with the report revealing solar panel prices have increased by about 20% over the past year.

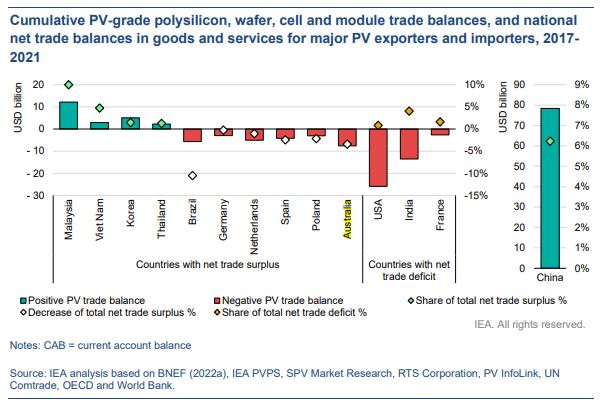

The imbalance of the solar supply chains has also had a marked effect on Australia’s balance of payments with the nation, which once led the world in developing solar PV technology, now one of the largest importers of PV components.

The IEA said in the past five years solar PV imports have reduced Australia’s trade surplus by 4%. During the same period, Australia ran an average trade deficit on solar panels and associated components of more than $10 billion (US$7 billion).

Federal Energy Minister Chris Bowen has backed the calls for an expansion of Australia’s solar PV manufacturing capacity, saying the nation needs to maximise the benefits of its world-leading research and development.

“The solar panels around the world, the technology that’s in them, in no small part was invented here,” he said last month when announcing the Federal Government’s $45 million extension of funding for the Australia Centre for Advanced Photovoltaics. “That’s something we can be proud of, but we’ve got to take it now to the next step.

“We’ve put 60 million solar panels on roofs in Australia in the last 10 years. One per cent of them have been made in Australia. That’s got to change. This is Australian technology, we want to see more of it made in Australia.”

The IEA estimates diversifying the supply chain could attract more than $170 billion (US$120 billion) of new investment in PV solar manufacturing facilities by 2030.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

4 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.