As the decommissioning volume keeps increasing, the proper disposal of PV modules has become an emerging environmental and social issue. But while the recycling of silicon PV modules is technically viable, it is often not feasible economically due to reasons that vary from high processing cost to low waste volumes that do not justify investment cost.

Now, a team of UNSW researchers has proposed a novel, simple, cost-effective and environmentally friendly method to recycle silicon PV modules. The process consists of module deframing, laminate shredding and material concentration using electrostatic separation.

The process outputs two fractions: a valuable mixture of silver, copper, aluminium and silicon, and a mixture of mostly glass, silicon and polymers. The valuable mixture accounts for only 2-3 wt% of the total module, which can be forwarded to the downstream industry for further refinement.

According to the researchers, the process can be profitable and is advantageous when dealing with small volumes, for instance 1,000 tons of solar panels a year.

Specifically, their paper evaluates the technical aspects of the process (quantifies material separation, energy and time) while using life cycle assessment and life cycle costing to evaluate the environmental impacts and economic prospects, respectively. The results are compared to a full recovery alternative (FRELP) and to landfilling.

Economic assessment shows the process has potential to be more profitable than FRELP at lower waste volumes (smaller than 4 kt/year), because of the smaller equipment capital cost, and if there is no market for the recovered glass, which is currently the case in many locations. Not to mention when the end-processing industry is located afar, since only the valuable mixture would require shipping.

Environmentally, a full recovery is preferred, followed by the proposed process, both of which have a net positive impact and are better than landfilling the whole module, the researchers write in their paper titled “High yield, low cost, environmentally friendly process to recycle silicon solar panels: Technical, economic and environmental feasibility assessment” published in Renewable and Sustainable Energy Reviews.

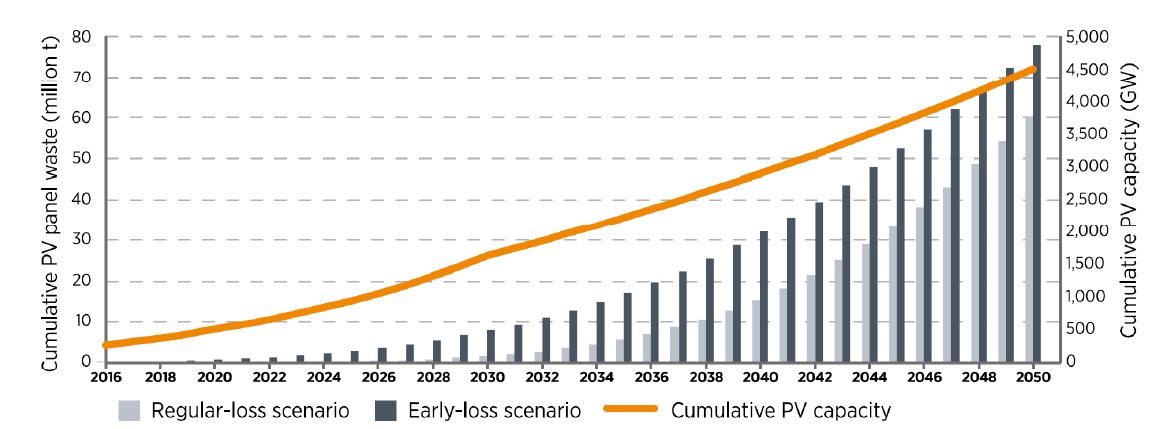

Around 1.7 million tonnes of waste volume of end-of-life PV modules are expected by 2030 under the regular loss scenario of a 2016 analysis by the International Energy Agency Photovoltaic Power Systems Programme (IEA PVSP) and the International Renewable Energy Agency (IRENA), with approximately 60 million tonnes expected by 2050. If the early loss scenario pans out, there could be 8 million tonnes of PV waste by 2030, and a total of 78 million tonnes by 2050.

And while recycling solar panels rather than sending them to landfills addresses an important environmental issue, material recovery is also projected to become big business.

Norwegian consultancy Rystad Energy estimates that recyclable materials from PV panels at the end of their lifespan will be worth more than $4.2 billion (USD 2.7 billion) in 2030, up from only $262 million this year, and the value will approach $123 billion by 2050.

Rystad projects that solar PV waste will grow to 27 million tonnes per annum by 2040, and they estimate that recovered materials from retired panels could make up 6% of solar investments by 2040, compared to only 0.08% today.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.