Brisbane-based Vecco Group will build what is being described as Australia’s first commercial-scale vanadium flow battery electrolyte manufacturing facility with the Townsville plant initially capable of producing enough electrolytes to support 175 MWh of energy storage capacity annually before scaling up to 350 MWh.

Vecco said the Townsville vanadium battery manufacturing facility will produce the electrolyte used in vanadium flow batteries, a proven option for large-scale energy storage, opening up downstream manufacturing opportunities and creating a new link in the supply chain. It will also support the development of Vecco’s Debella critical minerals mine near Julia Creek, about 650 kilometres west of Townsville.

The manufacturing facility is expected to commence production later this year. When operational, the company said it will produce nine megalitres of electrolyte annually, equating to an energy storage capacity of 175 MWh annually with plans to expand to 350 MWh.

Vecco plans to produce vanadium and high purity alumina (HPA) at its Debella project which will be integrated with the new manufacturing facility. The Debella project is expected to begin production in 2024 and is forecast to produce 5,500 tonnes of vanadium pentoxide per year and 2,000 tonnes of HPA annually over a mine life of more than 50 years.

Until the Debella project comes online, Vecco said it will use imported vanadium to produce high-grade vanadium electrolyte in Townsville.

Vecco Group Managing Director Thomas Northcott said the manufacturing facility will be a key enabler for vanadium flow batteries in the Queensland grid, with the technology providing a proven grid-scale energy storage solution with advantages including a long lifespan, lengthy storage capability and are non-flammable.

“We’ll be able to integrate mining and manufacturing and apply our expertise in critical minerals into the downstream supply chain to assist Queensland to achieve its renewable energy target,” he said.

“Australia’s demand for medium and deep duration storage by 2050 has been estimated at over 180 GWh by the market operator, vanadium flow batteries made right here in Townsville from Queensland’s minerals can help meet this need while creating good jobs in regional areas.”

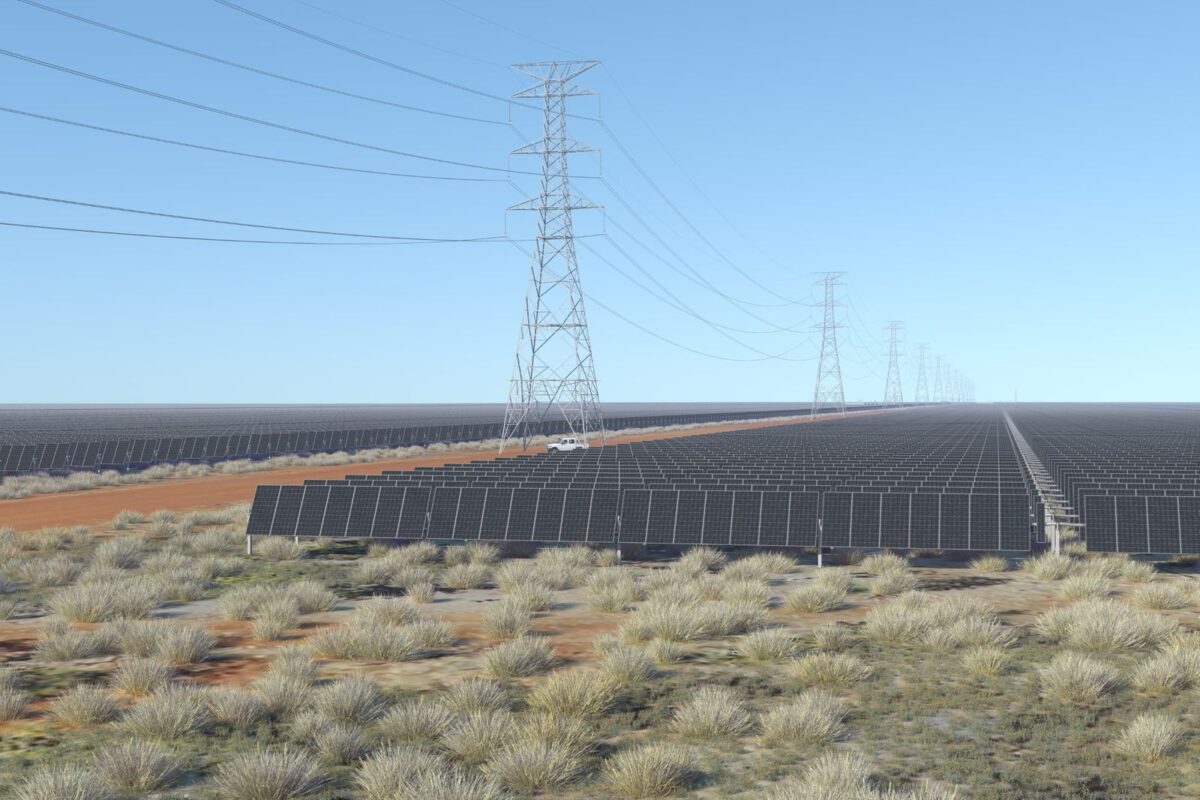

Image: Vecco Group

The Townsville manufacturing facility has been backed by the Queensland government through its Industry Partnership Program, and the project is part of the state’s $62 billion Energy and Jobs Plan, which includes creating a North Queensland battery industry supply chain.

Queensland Deputy Premier Steven Miles said the Townsville facility will be Australia’s first commercial-scale vanadium flow battery electrolyte manufacturing facility.

“This is history making,” he said. “Townsville will be the first place in the country to manufacture large-scale vanadium batteries. The batteries will be Queensland made and they will form part of a new vanadium supply chain, providing enormous possibilities for North Queensland.”

Miles said vanadium flow batteries will provide the grid-scale storage needed so renewable energy sources, like wind and solar, can reliably power Queensland homes, businesses and industries. The Queensland government is aiming to supply 70% of the state’s energy demands from renewables by 2032, and 80% by 2035.

“The ability to store and discharge energy on an industrial scale is one of the final pieces in the puzzle for decarbonising the electricity network,” Miles said.

The launch of the Vecco project comes just days after the Queensland government announced it will commit $5 billion to take control of and build the CopperString electricity transmission project that will expand the National Electricity Market (NEM) from Townsville to Mount Isa.

The 1,100-kilometre project will link Mount Isa, Cloncurry and the North West Minerals Province to the national grid, unlocking an estimated 6 GW of renewable energy in north Queensland.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.