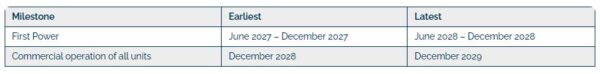

Federal government-owned utility Snowy Hydro has confirmed that the Snowy 2.0 pumped hydro project is facing up to another two years of delays that would push expected electricity production beyond its already delayed date of completion to December 2029.

The expansion of the existing 4.1G W Snowy pumped hydro scheme, originally forecast to provide 2 GW of on-demand generation and 350 GWh of long-duration energy storage to the National Electricity Market (NEM), was first announced in 2017.

The project, which involves linking the Tantangara and Talbingo dams via 27 kilometres of tunnels, was originally due to be operational by 2021 and was expected to cost about $2 billion but it has been plagued by time and budget blowouts. The last estimates had the cost of the project at close to $6 billion with some estimating that the all-up cost has now blown out to $10 billion-plus while the project was previously expected to come online in 2027.

In a statement on Wednesday, Snowy Hydro said it anticipates that the timeline for full commercial operation has been “delayed by a further 12-24 months” from the current publicly released dates, with likely “cost impacts beyond the contingency allowed.”

“A combination of factors have meant that it’s pretty clear that the schedule will go out by between one and two years,” Snowy Hydro Chief Executive Officer Dennis Barnes told Radio National. “Over the next few months, we’ll work through what the cost implications are.”

Snowy Hydro said its management team is working towards “resetting” the project’s delivery timeline and budget with principal contractor Future Generation – a joint venture between Italy’s Webuild and US-based Lane Construction.

Barnes, who took on the CEO roll earlier this year, said he wanted to place the project on a “realistic and sustainable footing while maintaining construction progress.”

“This project is critically important to the transition of Australia’s electricity grid and it’s crucial that we are working to a safe, efficient and realistically achievable timeframe to enable orderly planning for all our stakeholders,” he said.

“I am committed to being transparent about our progress and how we are proactively managing the inevitable issues and challenges that arise in a complex project like this.”

Barnes attributed the latest delays and cost increases to the effects of the COVID-19 pandemic, global supply chain disruptions, inflation and design changes sparked by the complexity of the project.

The developers have also encountered geological issues with tunnelling on the project taking longer than expected.

The latest difficulty has seen Tunnel Boring Machine (TBM) Florence, one of three machines drilling tunnels to connect the project, at a standstill for four months after becoming stuck in soft soil.

Barnes said the machine had only dug about 150 metres of the 15-kilometre tunnel since starting in November but expected the issue to soon be rectified.

“When the machine gets moving, which we’re expecting in weeks not months, then we do expect that the machine will move at the rate of more than 10 metres a day,” he said.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.