Nuvola Technology has unveiled its patented direct deposition separator technology, which could replace conventional film separators and deliver incremental improvements in safety and performance.

The SafeCoat Direct Deposition Separator material is the first product launched by the Los Angeles-based startup, formerly known as Millibatt. Under its previous name, the venture-funded company focused on small, rechargeable, high-density batteries for wearables, biomedical uses, and Internet of Things sensor applications.

Nuvola said that it has been selected as one of 10 winners in LG Energy Solution’s annual 2022 Battery Challenge. The competition brought together more than 100 companies with new battery technologies and business models.

SafeCoat is described as a chemistry-agnostic, drop-in solution for lithium-ion batteries compatible with mainstream lithium-ion manufacturing techniques. The porous polymer coating sprayed directly on the entire electrode surface encapsulates and protects them from a thermal runaway and a potential fire.

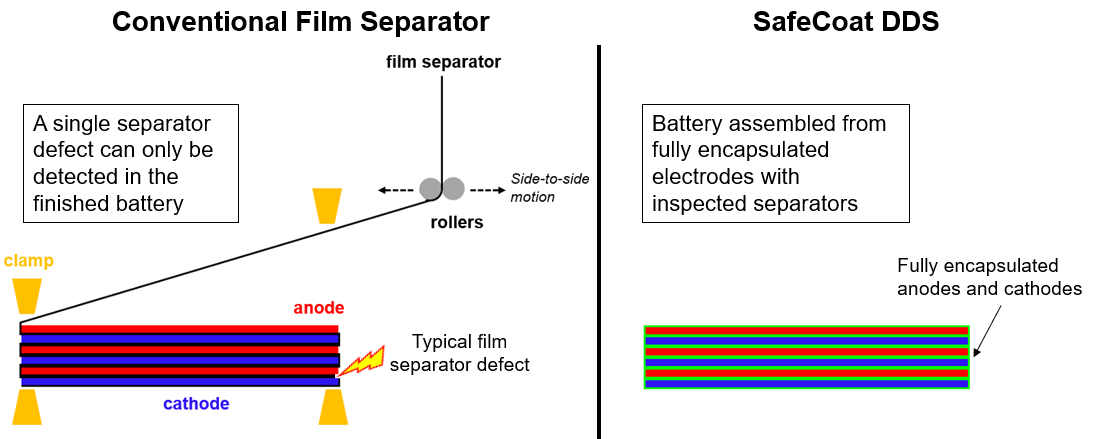

According to Nuvola, the battery system’s weak point are thousands of tissue-paper thin folded sheets of a porous plastic membrane that keep electrodes apart and make the battery prone to manufacturing errors and failure.

“During the battery assembly process, a single sheet separator can become damaged, creating an undetectable wrinkle, misalignment, misfolding, or even a tiny tear allowing the electrodes to come in contact. This may cause a fire – days, months, or years later,” said the company.

In addition to improving safety, Safe Coat is said to increase the active battery material volume, improving the energy density by up to 20%. Decreasing the thickness of the separator from the plastic film separator’s 20µm to SafeCoat’s 5 µm layer leaves more room for lithium ions in the same physical space.

According to the company, the Nuvola SafeCoat product is now under evaluation by several major battery producers and car manufacturers. It expect products using the technology to hit the market in 2025.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.