After introducing itself to the Australian market late last year, Chinese solar manufacturer Aiko is expecting to begin shipping as soon as its modules are listed on the Clean Energy Council (CEC) approved panels registry. The approval is expected no later than the end of March.

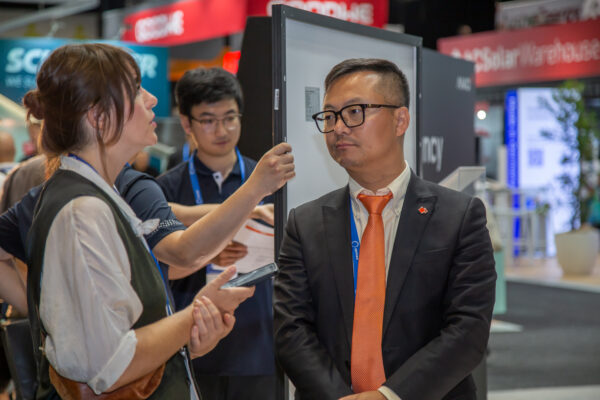

On the floor of the Smart Energy Conference held in Sydney last week, Aiko’s Back Contact (BC) module range stirred excitement. While generally the Australian solar market is split into two main streams – more affordable Chinese brands and premium European brands – Aiko is looking to buck this trend. It wants to position itself as a premium brand, although Aiko’s Asia-Pacific President, Alex Hang, says pricing will be competitive.

“We position ourselves as a premium brand but we cannot make it an unaffordable product… our aim is just to have a bit of premium but not a lot,” Hang told pv magazine Australia. According to the company’s Australian National Sales Manager, Ross Crawford, prices should sit between $0.30 – $0.35/W.

Image: Aiko

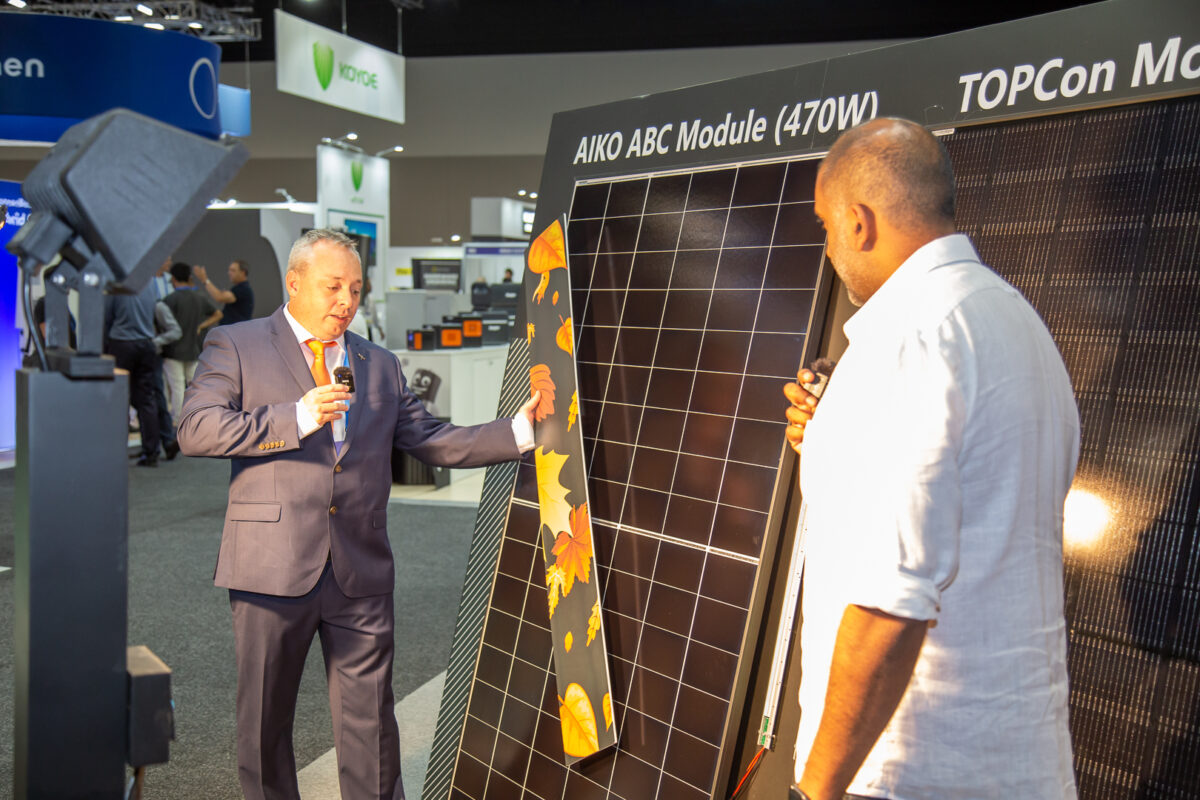

The ABC range boasts a 25.15% conversion efficiency, certified by TÜV-SÜD, with Alex Hang saying that this equates to between 20 – 30 Watts of additional power compared to a traditional panel of comparable size.

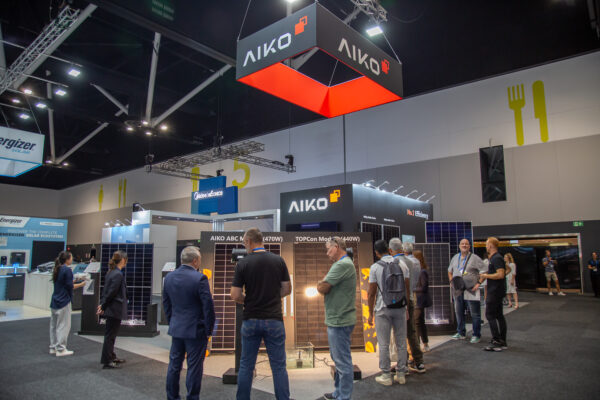

Specifically, the company’s residential panels from the ABC range, named Neostar, sit between 440W to 470W. The commercial and industrial (C&I) panels, the Comet series, sit between 605W to 630W. Meanwhile, the company’s utility-scale offering, the bifacial Polaris series, is between 620W to 640W. Hang also noted the company is launching a version specifically designed for floating solar.

With N-type TOPCon modules dominating global manufacturing, Aiko has taken a slightly different approach – still negatively doping its cells, but focussing on back contact (BC) panels. This approach, says Han He, Aiko’s Director of Product Management, has allowed the company to achieve its shading optimisation. “We can control the p-n junctions and also the voltage of the cell, sort of creating bypass diode function in every cell,” He explained. The details of exactly how this process works remains confidential, He said, but the end effect is that individual shaded solar cells are able to be bypassed without affecting the string.

Image: Aiko

Aiko started out manufacturing solar cells for many of the Chinese solar giants in 2009, but more recently moved into manufacturing complete solar modules. Its ABC module range has already been launched in Europe, with Crawford noting it has gained popularity in that market. Now Aiko is turning its sights on Australia, assuring that its distribution channels will cater not only to metropolitan cities but also regional and rural areas.

It has signed partnership deals with Australian distributors Solar Juice, AC Solar Warehouse, Sol Distribution, and Tradezone. Through these, the company has committed to delivering 2 GW of its GEN 2 ABC solar modules to Australian shores over the next three years.

The company has also introduced an ultra-lightweight 8.8kg module to the Australian residential market, swapping solar glass for high chemical plastic, affording the 450W ‘Air Series’ module its light weight.

Crawford said Aiko is planning a cross-country roadshow and a series of monthly online webinars to help educate installers about selling its technology in the Australian market.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.