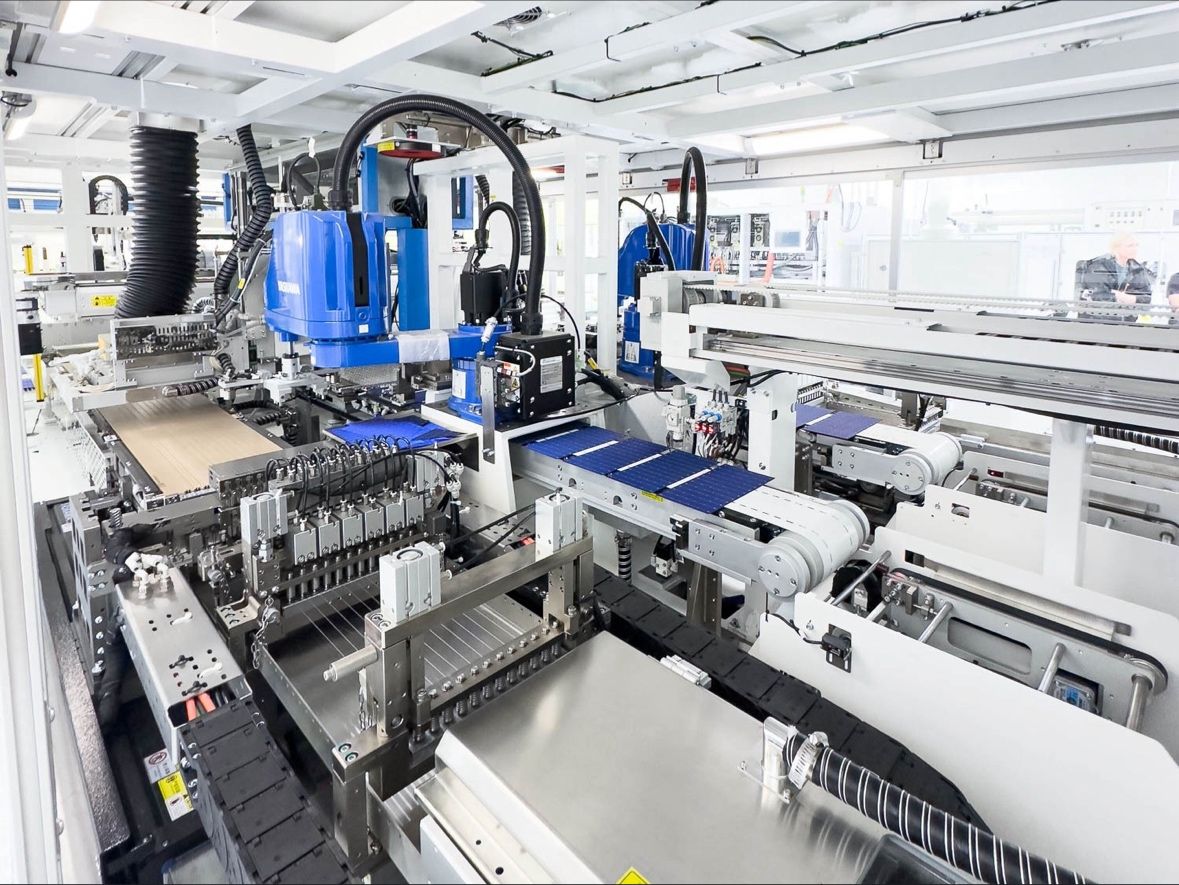

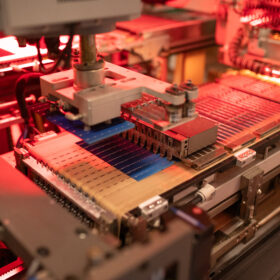

Sydney-headquartered solar technology company SunDrive Solar has achieved a copper plating production yield of more than 99% at its commercial pilot facility in Sydney, turning the cells into modules.

SunDrive has developed a cell metallisation technology that uses copper, which is approximately 100x cheaper and 1,000x more abundant than commonly used silver.

Supported with an $11 million (USD 7 million) grant from the Australian Renewable Energy Agency (ARENA) to develop its metallisation technology from prototype scale (1.5 MW / year) to commercial capacity (>100 MW / year), the recent milestone is clear proof of concept.

SunDrive Solar Chief Executive Officer Natalie Malligan told pv magazine it is proof of the commercial ability of SunDrive’s technology and proof the process and design concept works.

“The next step is to build the commercial scale tool and manufacture at actual commercial scale,” Malligan said.

SunDrive has been in collaboration with China-headquartered solar panel manufacturing giant Trinasolar for the past nine years, cemented with a manufacturing joint venture announced in October 2024.

“Part of our ongoing work with Trina is working on that technology integration and part of our plans for the industrialisation of our tooling would be through using an industrialisation partner on the tooling side but also working with Trina on how that would integrate into their cell manufacturing,” Malligan said.

The long term vision for SunDrive is to build a full supply chain in Australia to achieve true energy sovereignty along with environmental and economic benefits from local supply chains.

“There is a lot of work to do to build out a full supply chain but the most important first step is building that end product demand so that’s why the Australian government and SunDrive is preparing to do module manufacturing as the first step,” Malligan said.

“You really have to create that scale of demand for the end product and that is what will enable investments by companies like Capral Aluminium to build up their scale of supply and to become competitive on their costs.”

The ink has barely dried on a memorandum of understanding (MoU) between SunDrive and New South Wales-headquartered aluminium manufacturer and distributor Capral Aluminium to advance a sustainable and resilient local supply chain within Australia’s solar industry.

“The opportunity to source local and low-carbon aluminium through Capral has the potential to not only support Australian jobs and businesses but create a unique, Australian product that also supports jobs and enhances the resilience and sustainability of our production process,” Malligan said.

Capral Aluminium Industrial Solutions National Sales and Market Manager Mark Murray said the company supports SunDrive’s ambitions for domestic manufacturing and supply chains.

“We’re committed to exploring advanced manufacturing and automation solutions to meet the growing demands for SunDrive’s and Trinasolar’s modules, ensuring we remain competitive in the global market.”

Capral recent partnerships with primary aluminium suppliers offering materials with a minimum of 20% recycled content, further enhance the partnerships sustainability credentials.

Capral has successfully trialled the use of this recycled material in its extrusion plants, presenting an opportunity for SunDrive to incorporate the sustainable materials into its solar modules.

The partnership with Capral is contingent on SunDrive Solar securing support under the Australian Renewable Energy Ageny’s (ARENAs) Solar Sunshot program.

Sustained, long-term policy coordination and investment to strengthen Australia’s manufacturing capabilities and ensure global competitiveness are key to achieving a viable and cost-competitive local supply chain.

“Australia actually does have some competitive advantages when it comes to the manufacture of solar, in particular,” Malligan said.

“In terms of the natural resources or minerals required for solar, Australia is in the world’s top three providers of all of those key minerals, so we have a natural environmental advantage and increasingly overtime as the process of manufacturing becomes more automated, we become increasingly competitive as well.”

Malligan said being competitive points to the need for technology and is why the partnership with Trinasolar is important for Australia because a technological advantage is Australia’s strength.

“As many will know, Australia really is the inventor of modern day solar but also a lot of the foundational concepts of TOPCon technology, and SunDrive’s technology as well was founded through our founder, Vince Allen’s PhD at the University of New South Wales,” Malligan said.

“So, what Australia really needs to do is play to its strength, which is that technology innovation, combine it with the expertise of the world’s leading solar manufacturers and learn that manufacturing capability to enable a path to sustainable manufacturing in Australia with the added natural advantage of necessary resources.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.