Scientists from the University of New South Wales (UNSW) investigated the impact of UV-induced degradation (UVID) in solar cells based on tunnel oxide passivated contact (TOPCon) design.

Their analysis focused, in particular, on the role of hydrogen and wavelength dependence in the UV range, which they described as ambiguous.

“UVID is an increasing concern due to the use of UV-transparent encapsulants,” the research’s lead author, Bram Hoex, told pv magazine. “This enhances module efficiency but also exposes solar cells to UV radiation during operation.”

The researchers said that although there is still no scientific consensus about the causes of UVID, the main assumption is that it is caused by photons with an energy higher than 3.4 eV, which break the bonds between silicon (Si) and hydrogen (H), thus creating recombination-active dangling bonds. These, in turn, create recombination losses, which mainly affect the cell’s open-circuit voltage.

The novelty of the study is represented by the fact that the scientists considered for the first time the entire UV radiation spectrum, which includes UV-A radiation, which has wavelengths between 315-400 nm and is closer to visible light, and UV-B radiation, which is a high-energy, invisible form of solar radiation with wavelengths between 290-320 nm.

“We used UV-B for accelerated testing of TOPCon cells in lab conditions, enabling faster reliability assessments without introducing new failure modes,” Hoex said, noting that UV-B is commonly not perceived as a major concern, as the encapsulants commercially available in the PV industry effectively block UV-B radiation, leading to the idea that TOPCon module are fully protected by this potential degradation mechanism.

The race towards more efficient products, however, is pushing manufacturers to use encapsulants with a higher UV transmission, which increases risks.

“UV-B can significantly degrade the front surface passivation of TOPCon cells, leading to increased surface recombination,” Hoex said. “It can accelerate UVID in TOPCon solar cells, producing the same degradation effects as UV-A but at a much faster rate.”

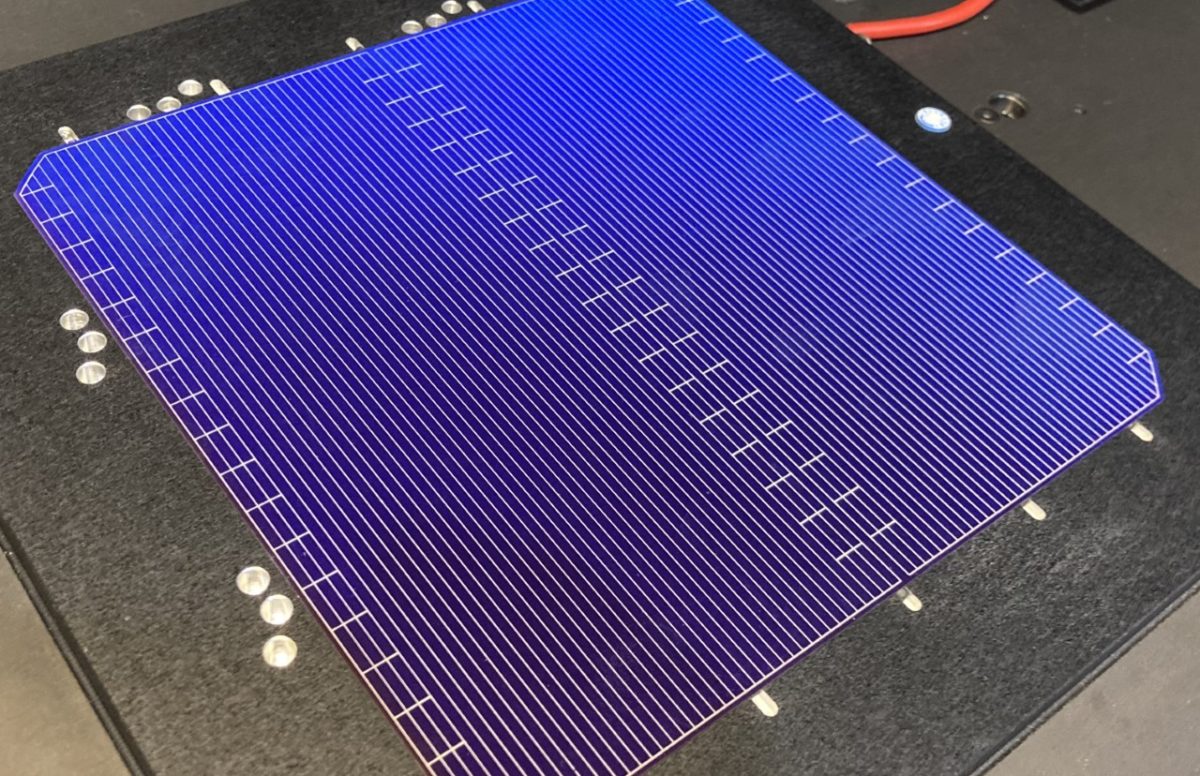

For their analysis, the academics used commercially available bifacial TOPCon cells based on n-type Czochralski (Cz) silicon wafers measuring 182 mm × 182 mm and with a thickness of 140 μm. The devices had a boron-diffused emitter on both sides, which was passivated by a 5 nm multilayer stack of aluminum oxide (AlOx) deposited by atomic layer deposition (ALD), and a silicon nitride (SiNx) layer anti-reflection coating.

The researchers also used a UV-A and UV-B lamp system at a temperature of 60 C to deliver a total dose of 61.1 kWh/m2 for UV-B and 49 kWh/m2 for UV-A radiation for the testing. They analyzed, in particular, the behavior of the cells before and after hydrogen release from the SiNx layer.

“We found that degradation occurs primarily at the TOPCon front surface, driven by Si-H bond breaking and hydrogen redistribution, increasing surface recombination, with rear surface showing strong UV resistance due to the doped poly-Si layer absorbing sub-370 nm photons,” said Hoex, noting that no light and elevated temperature-induced degradation (LeTID) was observed under UV exposure. “UV alters hydrogen dynamics in a way that suppresses this defect.”

The data showed that the UV radiation breaks the Si-H bonds at the AlOx/(p+)Si interface, which results in an increase in hydrogen ions. “However, the exact mechanism of this interaction and the long-term effects of altered hydrogen distribution require further investigation,” the scientists emphasized.

The research group said the industry should consider UV-B in accelerated testing of TOPCon cells in lab conditions, which would enable faster reliability assessments without introducing new failure modes. Furthermore, manufacturers should leverage rear-side UV protection by maintaining sufficient poly-Si thickness in design, while utilizing UV-resistant encapsulants and UV-filtering layers to control hydrogen distribution.

Their findings are available in the study “UV-induced degradation in TOPCon solar cells: Hydrogen dynamics and impact of UV wavelength,” which was recently published in Solar Energy Materials and Solar Cells.

Previous research by UNSW showed degradation mechanisms of industrial TOPCon solar modules encapsulated with ethylene vinyl acetate (EVA) under accelerated damp-heat conditions, as well as the vulnerability of TOPCon solar cells to contact corrosion and three types of TOPCon solar module failures that were never detected in PERC panels. Furthermore, UNSW scientists investigated sodium-induced degradation of TOPCon solar cells under damp-heat exposure and the role of ‘hidden contaminants’ in the degradation of both TOPCon and heterojunction devices.

Moreover, another UNSW study recently assessed the impact of soldering flux on heterojunction solar cells and found that the composition of this component is key to preventing major cracks and significant peeling.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.