Using excess heat from PV modules for lithium-extraction process

Canada-based Enertopia filed provisional patents for technology that it said could boost PV system output by 10% or more and reduce panel heat stress.

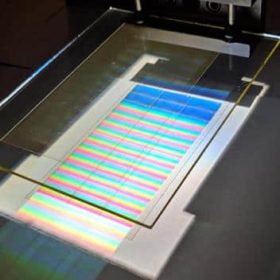

Holographic light collector to improve solar panel yield

In the proposed system, the optical element is placed symmetrically at the centre of the solar panel in order to increase the length of the effective light collection region. Each hologram is claimed to be able to separate the colors of sunlight and direct them to the solar cells within the solar panel.

Global solar supply chain remains under scrutiny

The discussion about the extent to which forced labor exists in the solar value chain continues. A video, a university report, a ministerial response and a parliamentary machinations formed notable developments of the debate last week.

Q Cells unveils 495 W solar panel with 21.4% efficiency

The Q.Peak Duo XL-G10.3 panel is currently the largest and most powerful product manufactured by the South Korean module maker. It is based on 156 monocrystalline ‘Q.antum’ half cells and is the company’s first panel relying on M6 wafers.

Panasonic launches 380 W heterojunction solar module compatible with its Evervolt battery

The new module series has a power output ranging from 370 to 380 W, a temperature coefficient of -0.26% per degree Celsius, and an efficiency of up to 21.7%.

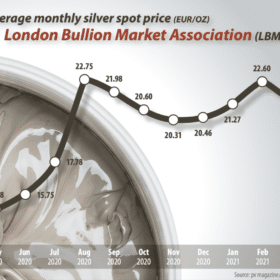

Sunday read: All that glitters is HJT

The devil is in the details, as they say, and when it comes to the next generation of mass-produced, high-efficiency PV cells, silver costs may be devilishly hard to reduce. Making things worse, prices for the precious metal are now heading in the wrong direction.

Q Cells announces n-type module with passivating contacts

Production on the new module, called Q.Tron, is expected to begin this year. The product is described as an evolution of the company’s Q.antum cell technology.

Solarwatt unveils two bifacial glass-glass panels with half-cell design

The most powerful of the two products has a power output of up to 380 W and an efficiency of 20.4%. For both panels, the temperature coefficient is -0.37%. The German manufacturer said the modules are produced at its manufacturing facility in Dresden.

Huawei enters Australia’s residential battery market with modular Luna2000

Chinese giant Huawei has entered Australia’s residential solar battery market with its home energy storage system, the Luna2000. The lithium-iron phosphate 5kWh cells have a modular design and are scalable to 30kWh. Huawei is banking on 10 kWh system capacities being most popular, telling pv magazine Australia they will retail for under AU$10,000.

Going fission! How scientific enquiry by UNSW may push solar cell efficiency to 38.2%

Cross-pollination of scientific and engineering thought within the ARC Centre of Excellence for Exciton Science has led to promising findings on the the cool solar-cell efficiency-boosting mechanism known as singlet fission.