Sinovoltaics tracks 86.5 GW of module output capacity for Southeast Asia

PV module manufacturing capacity in Southeast Asia has reached 86.5 GW across 61 active sites, according to Hong Kong-based quality assurance firm Sinovoltaics. The figures come from the company’s latest “Southeast Asia Solar Supply Chain Map” report.

The best tilt angle to improve PV system performance on low-income housing

Researchers have demonstrated that the theoretical optimal tilt for rooftop solar energy production in low-cost buildings in Nigeria is approximately 5.67°. Their modeling suggests to adopt south-facing roofs for PV generation in the southern hemisphere.

JinkoSolar achieves world record efficiency of 27.02% for TOPCon solar cell

The Chinese manufacturer said the result was certified by China’s National Photovoltaic Industry Measurement and Testing Center (NPVM).

Australian cell manufacturer launches first module series

Australian solar cell developer Halocell Energy has launched its first perovskite-based product line with the flexible Ambient Modules series purpose-built for low-light conditions.

Longi, Pertamina begin work on 1.4 GW solar cell, module factory in Indonesia

Chinese solar manufacturer Longi and Indonesian state-owned energy company Pertamina have started construction on a 1.4 GW solar cell and module production facility in West Java, Indonesia.

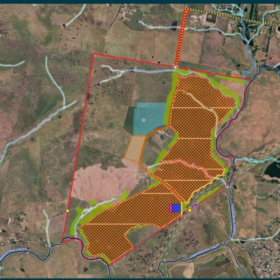

1.5 million solar panels sought in project procurement package

Procurement and works packages for what is set to be one of the largest solar farms connected to Australia’s main electricity grid are now live with developer Genex Power seeking expressions of interest from trade contractors and suppliers for the Bulli Creek Solar project.

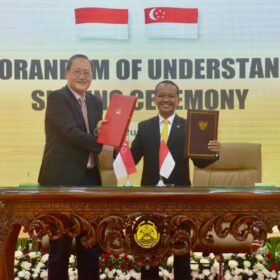

Indonesia, Singapore partner on solar supply chain in Riau Islands

Indonesia and Singapore have signed a memorandum of understanding to develop a solar manufacturing supply chain in Indonesia’s Riau Islands province, as part of broader plans to enable cross-border clean energy trading.

Trina Solar reveals 841 W perovskite-silicon tandem PV module prototype

China’s Trina Solar has unveiled a perovskite‑silicon tandem solar module prototype delivering 841 W and 27.1% efficiency, based on 210 mm tandem cells.

Australian manufacturer strikes 15 MW solar panel export deal

Australian PV panel manufacturer Tindo Solar has expanded its export market, locking in a new $8.4 million deal to supply 15 MW of solar modules for large-scale renewable energy projects in Vietnam.

Glass-free, coloured PV modules for building rooftop retrofits, facades

Researchers from Swiss and Austrian institutions have demonstrated a novel design for a glass-free, structurally robust silicon PV module. With a weight below 6 kg/m2, the targeted application is older buildings with weak roof structure.