Predicted energy use spike by 2030 flags need for smarter networks: report

A new report released by VisNet from EA Technology finds by 2030, Australian household energy loads are projected to rise 35%, with evening peak usage increasing by 60% in homes with electrical vehicles, prompting a call for smarter and more sustainable low voltage electricity networks.

AI energy management system to unlock virtual power plant potential

UNSW researchers will collaborate with Sydney solar battery installation company Aussie Solar Batteries to design, develop and test AI-driven energy management platforms capable of optimising solar and battery systems.

Trina Solar unveils 485 W TOPCon PV panel with 24.3% efficiency

The Chinese manufacturer has launched its third-generation Vertex S+ G3 dual-glass TOPCon modules for residential and commercial applications. The new products feature upgraded module architecture and a temperature coefficient if -0.26% per C.

Solar and wind assets achieve 5 TWh generation mark

Output from Australia’s large-scale renewable energy sector continues to climb with the nation’s utility PV and wind assets generating a total of 5.0 TWh in February, delivering an 11% increase on the same time last year.

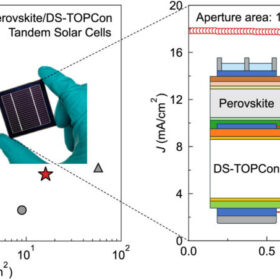

SERIS builds 22.1%-efficient perovskite-silicon tandem solar cell based on double-sided polysilicon layers

SERIS researchers have developed a 16-cm² perovskite-silicon tandem solar cell with a double-sided TOPCon bottom cell, enhancing passivation, reducing recombination, and increasing voltage and fill factor.

Trucking company tests solar-powered refrigerated trailer on Australian roads

With demand for low- or zero-emission logistics ratcheting up, cold-chain transport specialist Protran Solutions says a refrigerated trailer operating entirely on battery-electric power charged by solar has successfully completed a more than 1,600-kilometre trial run along Australia’s east coast.

Premier Energies unveils zero-busbar TOPCon solar cell

Premier Energies has unveiled India’s first zero-busbar TOPCon solar cell, a design that marks a structural shift from traditional 10 and 16 busbar architectures, replacing thick silver busbars with a dense matrix of ultra-fine silver lines to collect current.

JinkoSolar achieves record-breaking 26.66% efficiency for TOPCon solar cell based on M10-size wafer

The Chinese manufacturer claims the new efficiency result sets a world record for industrial-scale TOPCon solar cells on M10-size wafers. The achievement was verified by an undisclosed independent third-party organisation in China.

Construction begins on Hunter REZ transmission project

Construction has officially commenced on a network upgrade in the New South Wales Upper Hunter that is to boost transfer capacity in the region by at least 1 GW by 2028 in support of the state’s renewable energy transition.

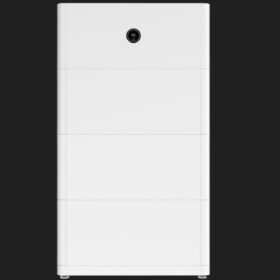

Growatt debuts high-voltage battery for residential, small C&I solar

The APX HV Battery 2.0 supports 5–30 kWh capacities and up to 15 kW of output. The IP66-rated system features a stacked, cable-free design.