Printed solar panels developed in Newcastle to power Tesla’s journey around Australia

Commercially printed solar cell technology developed by the University of Newcastle is being put to the test to power an electric vehicle’s 15,097 kilometre journey around the entire coastline of Australia.

Growatt unveils solar rechargeable portable power station

Chinese inverter maker Growatt has launched Infinity 1500, a portable power station for off-grid applications.

Weekend read: science or art? Defining the performance of bifacial modules

For some developers of ground-mounted PV, bifacial modules are already the default technology. The slight cost increase is often outweighed by an increase in energy yield. And yet “agreeing” on the right energy yield of a PV plant has always been the most heated debate between developers, investors, lenders, and technical advisers. Everoze partner Christophe Campistron looks at both sides.

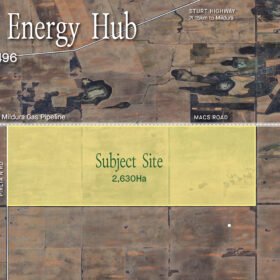

10 solutions to Australia’s foreign fuel dependence

Over 90% of Australia’s fuel is imported – something recent geopolitical events have illustrated is a serious vulnerability. This issue was the focus of an emergency fuel security summit held yesterday in Sydney. The event was attended by a number of industry leaders and independent members and candidates who put forward solutions to tackle the devolving situation.

Panasonic combines fuel cells, batteries, PV to power factory in Japan

Japan’s Panasonic claims its new pilot solar-plus-hydrogen facility marks the first attempt to create a factory powered by 100% renewables, via the full-scale use of hydrogen.

Solar greenhouse trials perform better than expected, proving commerciality company says

The results from solar glass company ClearVue’s greenhouse trials at Murdoch University have found the company’s product performed better than predicted overall, demonstrating both strong power generation and thermal value.

Natural hydrogen: how the potential wellspring works and why companies are pouncing

With its promise of cheap, easy ‘god molecules’ flowing inexhaustibly from the ground, it’s no wonder natural hydrogen is piquing interest. Sometimes referred to as ‘gold’ or ‘white’ hydrogen, Avon McIntyre, executive director of HyTerra, an Australian company in the space, told pv magazine Australia natural hydrogen projects should have smaller carbon footprints than sprawling green hydrogen plays and, moreover, would be ready quicker. Enticing as it sounds, unknowns remain.

Molecular thermal energy system can store solar energy for 18 years

Developed by a Chinese-Swedish research group, the device is an ultra-thin chip that could be integrated into electronics such as headphones, smartwatches and telephones. It combines a Molecular Solar Thermal Energy Storage System (MOST) with a micro-fabricated system that includes a thermoelectric generator (TEG) with a low-dimensional material-based microelectromechanical system (MEMS).

MIT-backed startup develops polymer-based batteries for stationary storage

The device is based on a standard, two-electrode electrochemical cell containing conductive polymers, a carbon-graphene hybrid, and a non-flammable liquid electrolyte. The battery cells were tested to perform for 12,000 cycles at 100% depth of discharge.

AI method learns from experienced staff on perovskite solar production lines

Academics from MIT and Stanford who have posited a new production method for perovskite solar cells have also developed a machine learning system which benefits from the experience of seasoned workers – and they’ve posted it online for anyone to use.