Outdoor testing identifies factors contributing to perovskite solar cell degradation

Tests conducted by a research team in outdoor environments in Spain and Poland have demonstrated a strong correlation between perovskite solar cell degradation and the combined effects of climatic and operating conditions. The scientists found that open-circuit operation accelerates degradation, whereas operation at the maximum power point and under short-circuit conditions has a lower impact.

$25.3 million finance to advance SunDrive copper solar cell technology

The Australian Renewable Energy Agency has committed $25.3 million to SunDrive to support its copper metallisation technology from development at its South Sydney facility to a 300 MW commercial-scale production tool.

ARENA backs Fortescue technology trial at a Pilbara solar innovation hub

The Australian Renewable Energy Agency is backing mining giant Fortescue with $45 million in funding, to trial new technologies that include methods to accelerate large-scale solar deployment and next generation solar construction techniques, at a Pilbara solar innovation hub.

Japanese companies partner to establish solar glass recycling scheme

Two Japanese companies have announced a partnership to advance the recycling of solar panel cover glass for application in architectural flat glass production.

Japanese utility uses Sharp PV-linked home batteries for grid balancing

Japanese utility Tohoku Electric Power is using Sharp’s residential batteries and AI-powered energy management systems to balance grid demand and optimise household solar energy use. Customers in the program can earn points redeemable for local products.

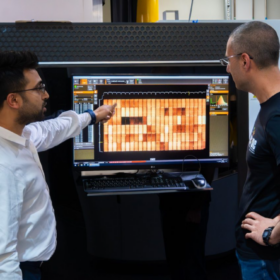

Solar cell inspection tool evolution set to slash manufacturing costs by billions

Researchers at the University of New South Wales in Sydney are working with the institution’s spinout company BT Imaging to accelerate the commercialisation of solar cell defect detection technology, thanks to a $1.4 million commercialisation project.

The impact of dust on PV systems in arid coastal environments

A Saudi–Egyptian research team investigated the effects of four types of dust on photovoltaic panels in arid coastal environments, finding that power losses can reach up to 48%.

Nextracker’s Earth Truss tackles tough terrain to unlock land for solar projects

United States-headquartered solar technology platform provider Nextracker has launched the NX Earth Truss foundation solution, that tackles tough terrain to unlock land for solar projects.

Electric truck achieves 480 kilometre delivery on single charge

Zero emissions trucking company New Energy Transport has demonstrated a 36-tonne heavy electric road freight delivery over 480 kilometres on a single-charge

AIKO signs 1 GW supply agreement with Australian distributors

Chinese solar manufacturer AIKO has signed a 1 GW supply agreement with Australian distributors and introduced its third generation all back contact Infinite series at All Energy 2025 in Melbourne.