From the June edition of pv magazine

As pv magazine tours UNSW’s solar projects, Bram Hoex, Deputy Head of School (Research) and Director of International Strategy says, “Our vision is to go to a several terawatt industry.” The projects of the university’s School of Photovoltaics and Renewable Energy Engineering (SPREE) span key areas of solar research that include the role of hydrogen, and development of stack or tandem cells.

In 2019, global PV installations are forecast to hit some 120 GW, but Hoex says solar is going to grow at least 10 times over the coming 10 to 15 years, and will continue that trajectory. Given the role of PV in future power generation, Hoex says, “We want to make the right choices.” By choices, Hoex means materials, methods, and technologies that deliver both high performance and low cost.

Like many of his colleagues, Hoex weighs up how he can spend his time and resources to have the greatest impact on solar’s efficiency and on lowering the cost of generation. Doing so effectively, and on a global scale, requires collaboration — a strategy that runs deep in the UNSW team’s veins, and that was instilled by the university’s solar luminaries like Martin Green, CheeMun Chong, and the late Stuart Wenham.

In the 18 months prior to the Australian federal election on May 18, Australian politicians of all stripes toured SPREE’s Tyree Energy Technologies Building, and the Solar Industrial Research Facility, and were reportedly inspired by the diminishing costs and rocketing learning rate that is propelling the penetration of solar technology. “Solar is still at a 20%+ learning rate – which means the more we make of it, the cheaper it gets, because we just get better at it”, says Hoex. But not all technological pathways lead to success, and the selection of research projects that the various UNSW teams work on provides insights into what shape the industry might take in the next 5, 10, or even 20 years.

Bifacial before tandem?

“Before we go further, I should stress that Martin looks at future technologies – where the world may be 20 years from now,” says SPREE Professor CheeMun Chong of his long-time friend, Martin Green, Director of the Centre for Advanced Photovoltaics. Chong says he thinks he was No. 8 among the hundreds of PhD students whom Green and Wenham have guided in harnessing the sun since they began their work in the 1980s. “Martin is a forward thinker and does great work in that area that none of us could hope to match,” says Chong.

Martin Green wears the future thinker’s mantle with a rare grace and generosity. Last year he became the first Australian winner of the prestigious Global Energy Prize, which hailed his contributions over more than three decades to solving the world’s pressing energy challenges. The Centre for Advanced Photovoltaics, which he now heads, combines the solar research of UNSW, Australia National University, Monash and Melbourne Universities, the University of Queensland, and the Commonwealth Scientific and Industrial Research Organisation.

Martin Green wears the future thinker’s mantle with a rare grace and generosity. Last year he became the first Australian winner of the prestigious Global Energy Prize, which hailed his contributions over more than three decades to solving the world’s pressing energy challenges. The Centre for Advanced Photovoltaics, which he now heads, combines the solar research of UNSW, Australia National University, Monash and Melbourne Universities, the University of Queensland, and the Commonwealth Scientific and Industrial Research Organisation.

Green’s 1980s invention, the PERC solar cell, has emerged as the most competitive crystalline silicon-cell technology in use today; PV InfoLink forecasts that more than 50 GW of PERC capacity will be added to the global array in 2019, bringing the installed total to 100 GW by year end. Sales of PERC cells are predicted to reach $1 trillion by 2040.

It follows, says Green, that investment in dominant technologies such as PERC will influence future developments, to the extent that, “a technology is going to have to show considerable advantages over PERC to be able to supplant it, particularly given its suitability for bifacial operation.”

Bifacial cells will soon become the norm, as the industry explores ways to best incorporate these output-enhancing components into modules and PV systems. Green foresees bifaciality boosting PERC cells’ current peak manufactured efficiency by “a couple of percent in absolute terms, to around 24%.”

As such, PERC is set to be the mainstream technology for the next 5 or 10 years, says Green, “unless we can get these tandem cells going, then you’ve got another period of efficiency gain that probably won’t stop for 20 or 30 years, where you just incrementally add more cells to a stack.”

Green’s group recently achieved 40.6% in laboratory conditions with stacked, or multi-tandem PV cells, and is now using computer modelling to identify new, earth-abundant, cheap, non-toxic semiconductor materials that will form those layers for future manufacturing at scale. In April, his team synthesised the first likely material from a group of known semiconductors that are characteried by their adamantine (diamond-like) atomic structure. Finding “a frontrunner to stick onto silicon” is SPREE’s most important project, says Green – despite commercial application likely being some 10 years away.

Benefits of hydrogenation

The role of hydrogen and its many potential impacts on crystalline silicon PV cells is an area of continuing research for UNSW. CheeMun Chong heads up UNSW’s SPREE hydrogenation group which is building on the pioneering work of Stuart Wenham who uncovered the fundamental reasons for its effects on cell efficiency. The group continues to help industry apply hydrogenation in targeted and beneficial ways.

In December 2017, the hydrogenation team received five significant grants from the Australian Renewable Energy Agency (ARENA) to further its hydrogenation work – essentially to improve the efficiency of different solar cell technologies either widely produced by manufacturers or emerging into broad application. With seven new postdoctoral researchers, and more than 15 PhDs, the group has swelled to around 30, and is deep into its four-year project cycle.

Dr Alison Ciesla, Wenham’s daughter, is involved in three of the ARENA-backed projects. She’s most excited about the methods she and co-lead Catherine Chan are exploring to control hydrogen in severely defected silicon such as cheap cast-mono wafers. She says cast-mono is seeing a resurgence and her team’s work on trapping hydrogen to achieve high rates of passivation in areas that most need it is generating great interest.

At the other end of the silicon quality spectrum, Ciesla is working on a project to improve the passivation of high-efficiency n-type solar cells. “The cost of n-type wafers is coming down because Longi is doing great work in that space, and a lot of companies are now pushing towards high-efficiency structures,” she says. Since the properties of n-type solar cells are different to those of more commonly used p-type cells, Ciesla is exploring how to manipulate hydrogen in new ways so that its passivation will create ultra-efficient n-type products.

Though such technologies “may never reach the same cost per watt as PERC, people are always willing to pay a bit more for high efficiency given their lower surrounding install costs – you can use fewer panels, which is better for small areas or whatever your limitation is,” says Ciesla.

UNSW’s hydrogen projects are also addressing heterojunction (HJT) technology. Brett Hallam, Scientia Fellow and Australian Research Council (ARC) Discovery and Early Research Award (DECRA) Fellow, is incorporating hydrogenation into the manufacture of HJT cells using extremely low-quality silicon. “Until now, only the best quality silicon could be used to make these devices,” says Hallam. “But the wafers we’re using are 40% cheaper, so if we can maintain high cell efficiency it could provide a very cheap way of producing solar cells in the future.”

Hallam’s project employs gettering – “a process where we suck as many impurities as we can out of the silicon” – and applies hydrogenation to neutralise remaining defects in the cheap materials. The project has already achieved an open-circuit voltage (VOC) of 700 millivolts. “The world-record solar cell using expensive float zone silicon had a VOC of 706 mV, so these breakthroughs show we’re not necessarily limited by the material quality,” says Hallam, who adds that the project is showing “large potential for further improvements.” His team’s hydrogenation work on HJT involves collaborations with Arizona State University and equipment supplier Meyer Burger.

Chong sees hydrogenation as a platform that can be applied to solar cell technologies as they are developed in coming years. He proclaims, “It’s just the beginning for hydrogenation, as we learn to use it in various and more clever ways.”

Partnership model

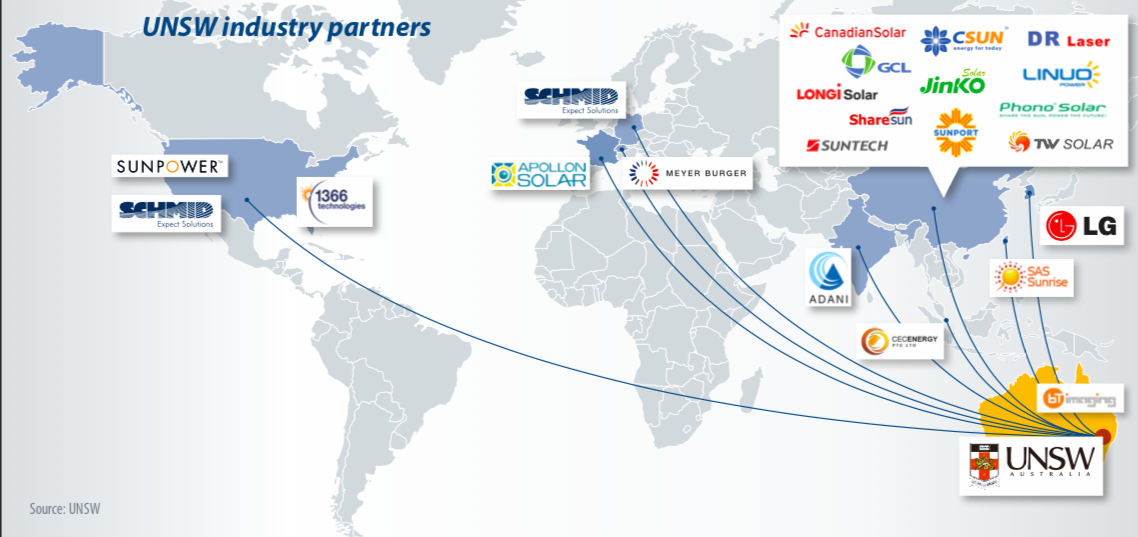

For the hydrogenation hub Wenham pioneered an industry-partnership approach that invites consortia of solar manufacturers to contribute financially to support the group’s research projects, and to participate in the development of technologies. They then have the right to deploy those technologies, royalty-free, in their production processes.

“We are insistent that we don’t work exclusively with one company – because it’s such a great platform, we want everyone to benefit from it,” says Chong. Hydrogenation partners include Jinko, Longi, SunPower, and Trina.

Most hydrogenation research consortia are also joined by equipment suppliers who get in early on understanding and contributing to development of the tools that will be required to implement any process on a commercial scale. “We don’t leave it to our cell manufacturer partners to figure out how to implement it,” explains Chong. “This has made the transition from university to industry so much smoother.”

Any process bound for the production line can also be tested and demonstrated at UNSW’s Solar Industry Research Facility (SIRF), which runs prototyping machines that can produce full-sized industrial samples. For example, Hoex explained, “We can do modifications on a solar cell that would be hard to do cost-effectively for a company.”

Manufacturers can only make money when a production line is running, and changing even one process to test it can be very expensive. At the SIRF, processes can be trialed at nominal cost. As Hoex notes, “The facility dramatically speeds up commercialisation.”

Beyond the lab, fab, and solar field, some UNSW projects extend into distant solar pastures.“I’m applying for funding to work on food security enabled by solar,” says Hoex. He argues that because solar is now so cheap and storage relatively expensive, using electricity as it’s generated is most effective, and we can “do stuff that would have seemed ridiculous in the past, like getting water from the air in the desert.” He’s assembling a broad-based UNSW group from the medical faculty and the Australian Human Rights Institute to present its case to the Bill and Melinda Gates Foundation.

Hoex declares optimistically, “We’re only scratching the surface of what we can do with solar!”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.