Australian National University (ANU) researchers have more than nudged the dial on efficiency of solar-to-hydrogen production that bypasses electrolysers and avoids AC/DC power conversion and transmission losses. They say their new world record of 17.6% efficiency, achieved with perovskite-silicon tandem absorbers, is open to further refinement that could see clean hydrogen production become cost competitive with other fuels, including brown hydrogen and gas, more quickly than expected.

In a paper just published in the journal Advanced Energy Materials, lead authors Dr Siva Krishna Karuturi and Dr Heping Shen write that although PV modules have become a commercially viable method large-scale renewable energy generation, “Achieving global renewable energy transition further relies on addressing the intermittency of solar electricity through the development of transportable energy storage means.”

With funding support from the Australian Renewable Energy Agency (ARENA) and the Australian Research Council (ARC), the ANU team has been exploring the potential of a process that Karuturi likens to nature’s process of photosynthesis. That is, it converts the sun’s energy directly into hydrogen in a photoelectrochemical (PEC) cell.

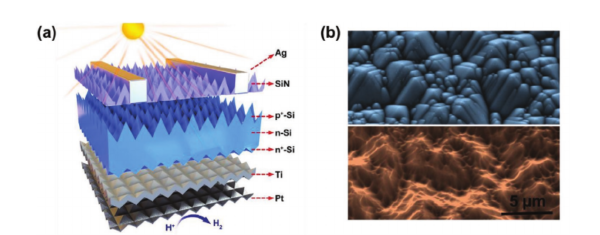

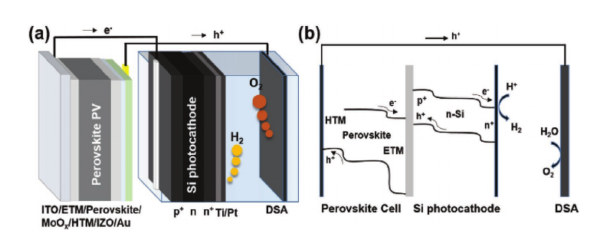

The introduction to the paper — which bears the catchy title Over 17% Efficiency Stand-Alone Solar Water Splitting Enabled by Perovskite-Silicon Tandem Absorbers — explains that the PEC cell “comprises a semiconductor photoelectrode immersed in an aqueous electrolyte that absorbs light, generating electron-hole pairs that participate in the hydrogen evolution reaction and oxygen evolution reaction”.

In 2009 the US Department of Energy, intent on providing a framework for viability of green hydrogen production set targets for PEC water-splitting efficiency of 20% by 2020, with 25% efficiency as the ultimate goal.

Although some semiconductors have demonstrated solar-to-hydrogen (STH) efficiencies of up to 19%, their high cost of materials has limited their application; at the same time, STH efficiencies achieved with inexpensive semiconductor materials have remained below 10%, and the materials themselves have been vulnerable to degradation.

The ANU researchers’ pairing of a buried p-n junction silicon/titanium/platinum photocathode with a semitransparent perovskite solar cell, is the first deployment of cheaper materials to achieve anywhere near 20% efficiency.

Image: Australian National University

“As revealed by our modeling results, the proof-of-concept demonstration offers immense opportunities to further improve the efficiency and reduce costs through optimisation of the performances of the individual components and replacement of precious catalysts with abundant materials,” writes Karuturi.

He describes his team’s solution as “An elegant and potentially economical route to storing solar power.”

Image: Australian National University

Funded under ARENA’S Advancing Renewables Program since August 2018, the project was anticipated to contribute to “the development of a potential renewable energy export supply chain through the research and development on the production of gaseous hydrogen using solar energy”, ARENA noted at the time.

At the end of March this year, BloombergNEF’s Hydrogen Economy Outlook calculated that renewable hydrogen could be produced for US$0.8 to US$1.6/kg in most parts of the world before 2050. “This is equivalent to gas priced at US$6-12/MMBtu,” wrote Kobad Bhavnagri, Head of Industrial Decarbonisation for BNEF and lead author of the report, and would make it competitive with natural gas prices in many countries on an energy-equivalent basis.

These calculations relied in part on the continually reducing costs of electrolysers. The PEC process, however, in bypassing the electrolyser step of envisaged large-scale green hydrogen production, and its attendant limiting cost factor, shows the ANU team’s work to be a potential game changer in the race to produce commercially viable hydrogen.

“Hydrogen is promising and powerful because it can be used for so many things,” said Bhavnagri, who cited its potential to replace fossil fuels in hard-to-abate sectors of the economy such as steel making, aluminium processing, providing dispatchable energy, producing ammonia, and powering trucks and shipping.

Thus deployed it could erase one-third of today’s global emissions from fossil fuels and industry.

But Bhavnagri emphasised that to achieve its promise as a green fuel, hydrogen would need rigorous policy support to drive world economies to net-zero emissions, including putting a price on carbon.

Such clarity of purpose to mitigate climate change is not to be expected from the Australian Federal Government which stubbornly maintained a “technology neutral” approach in Australia’s National Hydrogen Strategy released late last year, and in May passed new legislation designed to support the production of hydrogen from brown coal.

In its Technology Investment Roadmap Discussion Paper, the Government set the stretch goal — dubbed ‘H2 under 2’ — of producing hydrogen for AU$2 a kilogram, by any means. Cost-competitive clean hydrogen generation can’t come soon enough.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.