Engineers at the University of New South Wales (UNSW) have whipped out their best grid paper, sharpened their pencils and got down to work at what engineers do best, fix things that are broken. In this case, the broken thing is Morrison Government policy. Specifically, the National Hydrogen Strategy which assumes its goal of ‘H2 under $2’, the production of hydrogen or $2 a kilogram, is not achievable through green hydrogen alone.

In a paper published this week in Cell Reports Physical Science, the UNSW researchers reveal that green hydrogen production’s costs are nowhere more susceptible to fall than in Australia with our abundant solar resources.

The researchers ran thousands of calculations using an assortment of values for various parameters and scenarios to determine a range of costs of green hydrogen which reach US$2.50 at bottom. This price may not be H2 for $2 yet, but it is certainly competitive with fossil fuel generated hydrogen.

UNSW’s School of Photovoltaic Renewable Energy Engineering postdoctoral fellow Nathan Chang said that these results are even more encouraging considering technology performance and costs will improve over time.

Co-author Rahman Daiyan, of ARC Training Centre for Global Hydrogen Economy and UNSW’s School of Chemical Engineering, said that certain parameters stood out when the numbers approached US$2. “Capital costs of electrolysers and their efficiencies still dictate the viability of renewable hydrogen,” says Daiyan, “One crucial way we could further decrease costs would be to use cheap transitional metal based catalysts in electrolysers. Not only are they cheaper, but they can even outperform catalysts currently in commercial use.”

Australia’s inherent comparative advantage

It was an undergraduate student by the name of Jonathan Yates who actually built the system and cost simulation model as part of a project through the UNSW’s Taste of Research scholarship program. Evidently, Yates did get a taste for research, and is now well on his way to gluttony.

“We used real weather data and worked out the optimum size of the PV system for each location,” says Yates. “We then saw how this would change the economics in different locations around the world where solar-powered electrolysis is being considered.”

Unsurprisingly perhaps, the model demonstrated that a place like Japan, with limited land area and less monotonously sunny weather, has a lower cost potential than Australia, and thus becomes a prime export opportunity.

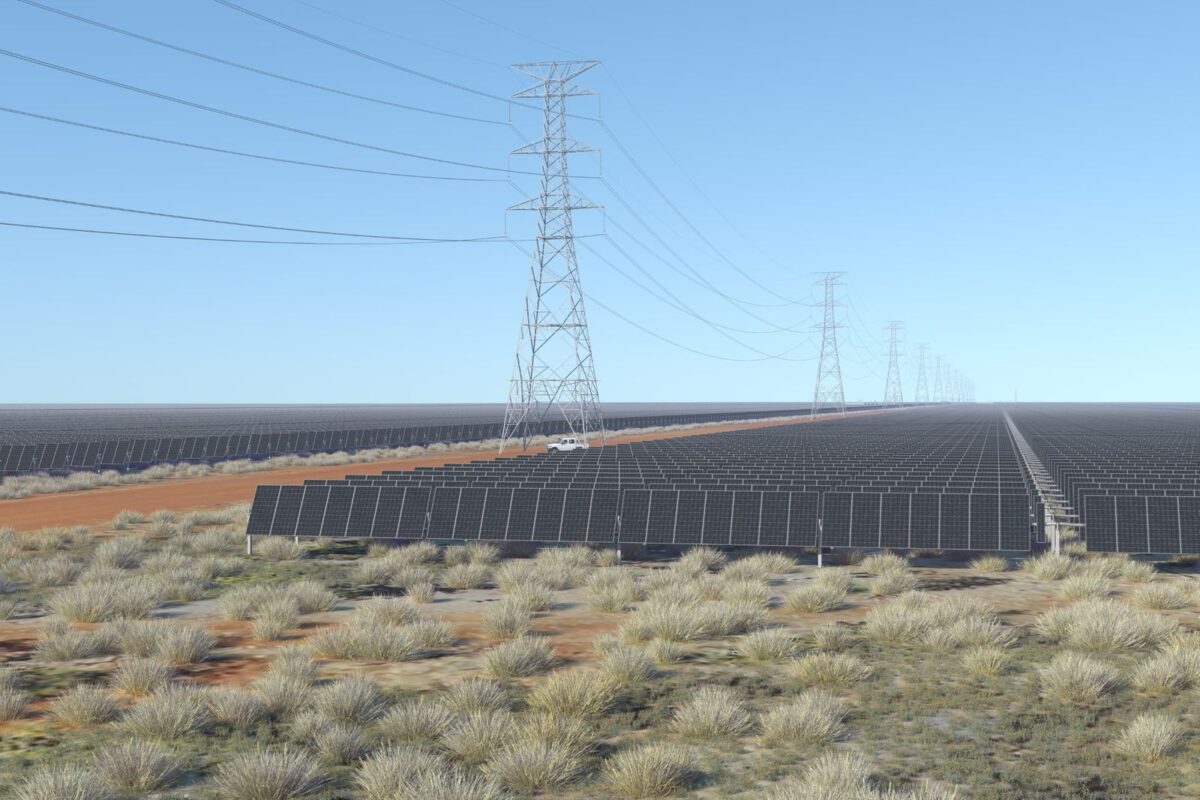

“So there is potentially a significant cost difference when compared to the spacious outback regions of Australia, which have plenty of sunlight,” concludes Yates definitively.

In this light then, this particularly sunny light we enjoy in Australia, the researchers say that not only is not it not far-fetched to imagine large scale green hydrogen energy plants becoming cheaper than fossil fuel powered plants in the coming decades, but that the numbers are very much on green hydrogen’s side.

“Because PV costs are reducing, it is changing the economics of solar hydrogen production,” said Chang. “In the past, the idea of a remote solar-driven electrolysis system was considered to be far too expensive. But the gap is reducing every year, and in some locations, there will be a cross-over point sooner rather than later.”

Inevitability

The numbers then, as they say, have been crunched. Despite Energy and Emissions Reduction Minister Angus Taylor’s determination to reach H2 for $2 ‘by any means’, the numbers mean that actually the future of hydrogen is green. To establish Australia’s hydrogen industry on fossil-fuel generation now would be like surveying the aviation transport industry in the early 20th Century and betting on dirigibles. Taylor’s plan is for Australia’s hydrogen economy to go up like the Hindenburg.

Yates notes that it is only a matter of time before green hydrogen is more economical than fossil fuel generated hydrogen. “When we recalculated the cost of hydrogen using other researchers’ projects of electrolyser and PV costs, it’s possible to see green hydrogen costs getting as low as US$2.20 per kg by 2030, which is on par or cheaper than the cost of fossil-fuel produced hydrogen.”

Of course, the UNSW researchers are not the only people who ran the numbers. Hydrogen fuel is more than just big business, it has the potential to power big business. In fact, according to a study from IHS Markit earlier this year, green hydrogen will reach price parity with grey and blue hydrogen by 2030, if not earlier.

“As this happens,” says Yates finally, “Australia, with its great solar resource, will be well placed to take advantage of this.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.