Australian manufacture has been a slow burner in the solar industry, but on Friday Solpod, engineers and producers of relocatable rooftop solar arrays, announced an innovative new solar mounting system that is being made by Ullrich Aluminium in Australia, and branded and supported through the Australian distribution network of Schletter, a German-headquartered global leader in solar mounting solutions.

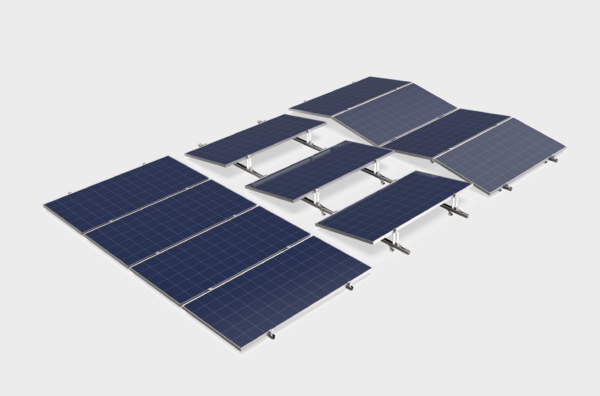

Schletter will market the product as the Schletter Eco Commercial Tilt (SECT) range, which consists of seven stock-keeping units (SKUs) that can be used to mount east-west tilted rooftop arrays, north facing arrays or flush-mount solutions using the same design language.

“The minimal number of parts helps everyone in terms of inventory, because it means you’ve got greater confidence that you’ll be able to use any spares,” Solpod CEO James Larratt told pv magazine.

Larratt said that, “As big as the Australian solar industry is, it hasn’t been looking for opportunities to manufacture,” because many people assume that solar components made in Australia simply can’t compete with product mass produced in Asia.

The SECT system, however, was designed from the outset, with onshore manufacturing systems in mind, to be cost competitive: “There are some things in Australian manufacturing of aluminium extrusions that we can do more competitively and there are some things where we’re just so far off the money.”

Tested and approved by the German engineering giant, SECT incorporates a number of features developed from Solpod’s long understanding of the Australian market and designed to enhance the safety of installers, as well as make their workflow smoother:

- The range claims a new level of best practice in Occupational Health and Safety because it eliminates the need for rooftop installers to reach across the one-metre width of panels to tighten clamps; this not only reduces the risk of back injury, but also minimises unintended damage to panels, which can occur when installers lean on them and create microcracks that degrade panel performance over time.

- Automatic earthing, says Larratt, is a SECT innovation that means “you only have to Earth the mounting solution and it earths all the panels, where you’d typically need to run an earthing cable to each panel”.

- The system includes a cable channel (see below) that efficiently manages all the cables of an installation, “Otherwise installers have to loop up and clip all the cables so they’re not just blowing in the wind,” says Larratt.

Image: Solpod/Schletter

Managing Director of Schletter Australia, Trevor De Vries, said in a statement, “Our partnership with Solpod on SECT is a wonderful endorsement of Australian innovation and manufacturing, and adds real depth to our product portfolio.”

Larratt reports that the feedback from installers so far is that the features of SECT make their lives easier, and that there is great support for the idea of an Australian-made mounting solution.

The potential for job creation

Ullrich Aluminium, a New Zealand-based company that entered the Australian market with the establishment of two branches in Sydney and Melbourne in 1988, now has some 27 warehouses throughout Australia so “there’ll always be somewhere pretty local for installers to be able to order from,” says Larratt.

Conservative estimates suggest that manufacture of SECT will create 15-20 new jobs at Ullrich in the first year of production, but if Australian installers were to buy only Australian-made mounting systems, Larratt calculates that some 1,200 jobs would be created.

pv magazine currently knows of only one other Australian-made mounting product — the Cutter Rail — designed by Australian solar engineering, manufacturing and marketing firm Clenergy in consultation with local quality installer group Solar Cutters, and manufactured in Australia by Capral Aluminium.

The installer relationship is vital

“You’ve got to have that really close connection with installers to know their response,” says Larratt, “and when everything is imported, the relationship to the Australian installers is obviously not as strong as it could be.”

Larratt says it was because Solpod was working on the Solpod Mini — independently launched on Friday — as a response to market demand, that its engineering team headed by Jeremy Lawrence, began really investigating both the benefits and limitations of existing mounting systems.

Image: Solpod/Schletter

The original Solpod relocatable solar system was designed for commercial customers that are renting premises, and are unlikely to have a lease that matches the 25- to 30-year lifespan of today’s solar installations.

They can buy, lease or enter into a power purchase agreement for the Solpod 4 x 5-metre, 5 kW prefabricated and adhesive-fixed pods, and pack them up for installation at a new site, or sell them when their lease is up — a concept that offers maximum flexibility.

Solpod has installed some 3 MW of its relocatable system since launching in April last year, including on the building that houses the Australian headquarters of Google, Workplace6 in Sydney’s Pyrmont, but found that many rooftops had other hardware — piping, air-conditioning units and so on — that got in the way of installing its 4 x 5-metre solutions, which are craned into position and can be installed in as little as 10 minutes.

Leveraging know-how from one system to new opportunities

“We did a lot of engineering on the big pod,” says Larratt, “and we thought: Do we just walk away from these other opportunities?”

The company opted to design its second offering as a fixed, non-relocatable rooftop system to suit any commercial roof, and returned to rooftop assembly but in a streamlined configuration: each module is held at four points using edge brackets and dual-function centre brackets: these brackets provide a slide-in function on one side, and a clamp function on the other, ensuring that modules can be secured in sequence, with the clamp always on the installer side.

Image: Solpod/Schletter

Solpod Mini’s mounting solutions became the SECT range when “Schletter got wind of our Mini. They were keen to have a new product for the Australian market,” Larratt told pv magazine.

Customers will benefit from Schletter’s established and reliable sales, engineering and support team in Australia, and there is potential for the Australian-designed and manufactured SECT range to be exported to other markets.

Locally, Larratt says, “There’s a huge amount of interest in Australian-made at the moment, and we’re excited by the encouragement we’ve received from industry for this product range.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

Nice article Natalie. The SolPod system is interesting as it can be relocatable. Well done on the partnership with Schellter.