Australian battery manufacturer Energy Renaissance (ER) has unveiled a $1.46 million battery management storage (BMS) development project which will see it design and manufacture a defence-grade cybersecure BMS in collaboration with Australia’s national science agency, the CSIRO.

The project also has the support of the not-for-profit, independent Innovative Manufacturing Co-operative Research Centre (IMCRC) which is matching ER’s financial commitment dollar for dollar.

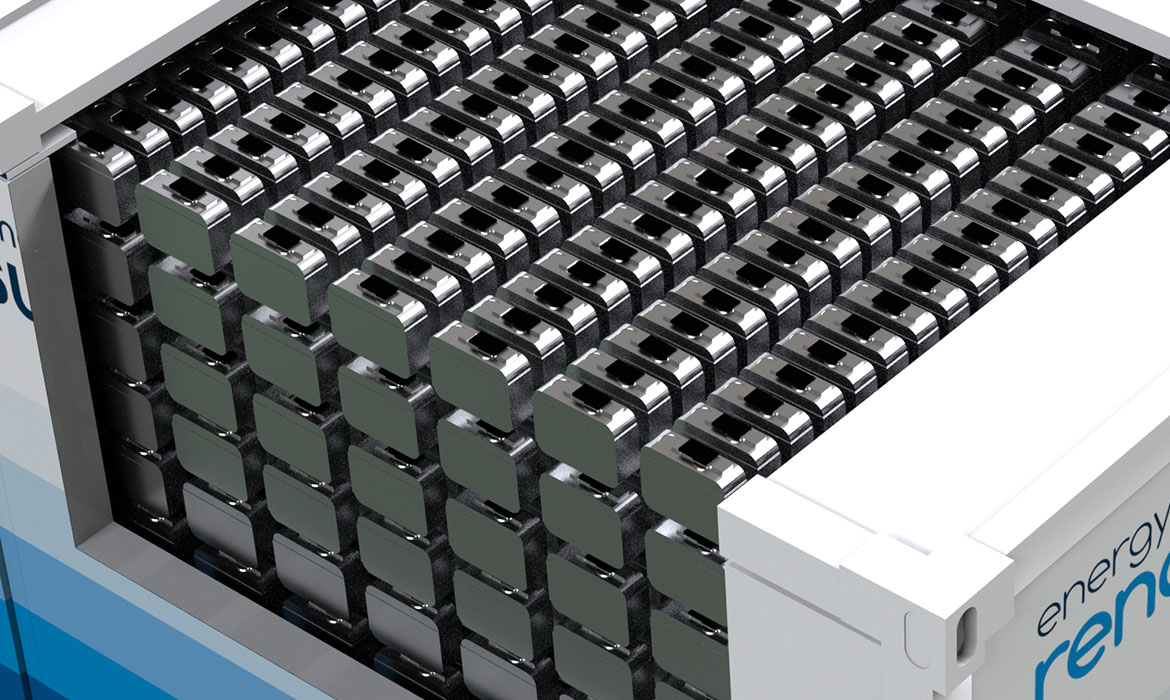

Brian Craighead, ER’s director of technology and development, said the Australian-made and manufactured BMS will be coupled with the company’s superStorage series of renewable-energy-storing lithium-ion batteries which are to be manufactured at its $28 million facility in Tamago in the New South Wales Hunter Valley.

“We have spent a lot of time and money designing the superStorage platform to allow us to do all the things we promised, to make things safer, cheaper, faster, better for the Australian and South-East Asian markets,” Craighead told pv magazine.

“The end result is a plug-and-play battery system that works for us and the battery management system is at the heart of it.”

The BMS will monitor and report on the battery’s usage, lifespan and faults through a mobile network to ER and its customers. Communicating through an inverter, the system will enable secure real-time data, analytics and remote management to drive down the risk of battery failure and operating costs for grid-scale energy storage users.

ER is also determined the BMS will provide customers with certainty regarding the sovereignty and security of the software and hardware.

“The collaboration between Energy Renaissance, CSIRO and IMCRC will promote an Australian Battery Management System instead of relying on an overseas technology platform,” Craighead said.

“Working together with CSIRO will ensure we can create a world-class, defence-grade cybersecure Battery Management System that is fully developed and managed in Australia for critical energy storage infrastructures.”

Image: ER

Craighead said providing assurances about the sovereignty and cyber security of the BMS is crucial to the energy storage industry moving forward.

“We can’t expect defence, we can’t expect government, we can’t expect large companies to trust the adoption of clean energy systems if we don’t trust the software completely,” he said.

“As you plug batteries into mission-critical systems – building management systems, energy management systems – we believe it is very important that the software that runs those batteries are protected from nefarious actors or even incompetent actors.

“It’s not now considered very high risk because it’s early days but if history has taught us anything, it will go from being a small issue to mission critical in the space of one event.”

Craighead pointed to the SolarWinds incident which has rocked disparate industries across the United States in recent months as a prime example of the need to have secure BMS software in place.

In that incident, nation-state hackers, now presumed to be Russian interests, gained access to government and commercial networks via an IT monitoring platform update rolled out by U.S. software firm SolarWinds. The hack is known to have breached, among others, the departments of Energy, Defense, State, Homeland Security, Treasury, Commerce, and its National Nuclear Security Administration.

“When it comes to software, when it comes to integrity of the system powered by software. I always go back to first principles, you need to know where things come from,” Craighead said.

“If you’re not sure of the sovereignty of it and completely sure of where it came from, who wrote it and for what purpose, then you are opening yourself to risk. And the risks are very real.”

Dr Adam Best, CSIRO principal research scientist Dr Adam Best has been seconded to ER to help develop the BMS and said the “exciting” project is progressing well.

“We’ve already started looking at the architecture of the cyber security aspects and are trying to map out the threat matrix,” he told pv magazine.

“In terms of the actual hardware and software, we have chosen our cell chemistries. We have some cells which have been shipped in and we have already started testing those.”

Best said the BMS will serve as the ‘nerve centre’ for the battery and will make them safer, more affordable and optimised to operate in high-temperature environments.

Image: ER

David Chuter, CEO and Managing Director at IMCRC, said the research collaboration between ER and CSIRO could serve as a catalyst for further establishing an Australian battery manufacturing sector.

“The growing interest in renewable energy and thus demand for lithium-ion batteries provides a great opportunity for Australia,” he said.

“Through accessing local knowledge and expertise, this project will demonstrate how we can utilise Industry 4.0 technologies and principles to establish a viable Australian battery manufacturing sector for the benefit of all Australians, and as a national manufacturing priority.

“The commitment from all involved in this project will help position and strengthen the value and influence of Australia’s role as a strategic partner in the global lithium-ion battery value chain.”

While ER offered no definite date for the release of the BMS it did confirm it would be part of the first superStorage batteries which are due for commercial release by July.

“When we release the superStorage range of batteries, it will have our own BMS in it,” Craighead said. “You’re talking about somewhere about June, July.”

Meanwhile, Craighead said work is progressing well on its 4,500 sqm purpose-built manufacturing facility with completion expected in late September. When the Tamgo facility is operational it is expected it will have an initial battery production capacity of 66 MWh per annum, with plans to scale the operation up to 5.3 GWh.

Until then, ER is planning to lease a facility which will allow it to produce batteries on a smaller scale to meet existing demand.

The Australian-made batteries will power stationary (grid and microgrid, renewables, community storage, mining electrification) and transport (buses, light commercial and industrial vehicles) applications.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

1 comment

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.