JinkoSolar’s as yet unaudited financial results for Q4 2020 and for the full 2020 year place it as the world’s largest PV manufacturer, with module shipments of 18,771 MW — an increase of 31.4% year on year, despite what Xiande Li, the company Chairman and CEO, described as a “challenging year for the solar industry as global markets were shrouded in uncertainty due to the COVID-19 pandemic”.

The company posted total revenues of US$5.38 billion, up 18.1% on 2019; and non-GAAP (according to US Generally Accepted Accounting Principles) net income of US$146.9 million, which was 1.2% down on 2019. It’s gross margin calculated across 2020, was 17.6%, compared with 18.3% in the full year 2019.

Looking ahead, Li said the company expects “total shipments in 2021 to grow over 30%, to be in the range of 25 GW to 30 GW”; while annual in-house production capacity will reach 33 GW of monocrystalline silicon wafers, 27 GW of solar cells and 37 GW of modules.

Li credits the company’s integrated operations and supply chain management for its resilience against continuous volatility in the industrial value chain, which he predicted was likely to continue into the second quarter of 2021.

But, he said, “As the world enters into the era of grid parity,” in which renewables-generated electricity comes at a lower or equal price to that generated by traditional fossil fuels, JinkoSolar expects “to solidify our foothold in major regions worldwide”.

Australian rooftops the icing on the big solar slice

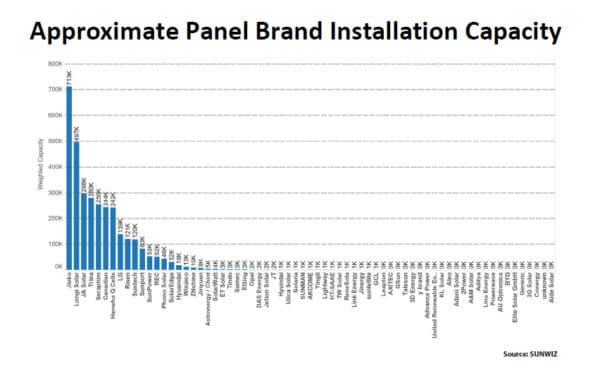

According to strategic solar consulting firm SunWiz, JinkoSolar captured 22%, the highest market share, of the Australian distributed rooftop generation market.

Anita Li, General Manager of JinkoSolar for APAC and ANZ, was “excited to confirm our leading position in the Australian market as the No.1 modules supplier in the national rooftop business”.

Image: SunWiz

In January of this year JinkoSolar had already claimed the biggest share — more than one-third by end 2020 — of the Australian utility-scale solar market, based on data available on the Australian National Electricity Market Dashboard.

At the time, it looked forward to claiming 1 GW of the nation’s utility solar capacity, when the Sunraysia, Glenrowan, Jemalong and Batchelor solar farms were fully commissioned this year.

Biggest and best?

January 2021 also saw JinkoSolar pad proudly away from the podium bearing the pv magazine best Module award for its high-density Tiger monofacial module.

“The technology is really innovative,” explained juror Jay Lin. Jinko’s Tiger deploys tilting to great effect, packing 156 half cells into the larger module format for utility-scale and C&I roofs, and 132 for the residential segment. Thus, the Tiger achieves 455-475 W from 156 cells and 375-395 W from 132 – both using mono PERC cells.

“At 21.6% module efficiency, Jinko’s Tiger is no pussycat,” the jurors representing the industry concluded.

The company says it expects its new-generation Tiger Pro flagship products to “account for 40% to 50% of the total shipments this year, with cumulative orders of over 10 GW”, but it is as yet uncertain when the high-performing residential and C&I Tigers will come to bask on Australian rooftops.

Future proofing, future plans

Xiande Li said that although the “mismatch between supply and demand” that emerged in the last quarter of 2020 was continuing to drive volatility in the solar market, “there is enough polysilicon to support over 180 GW of module production”.

February this year saw the company line up a strategic cooperation agreement with Tongwei Co. “to jointly invest in a high-purity crystalline silicon project with annual capacity of 45,000 metric tons and a silicon wafer project with an annual production capacity of 15 GW”.

Also in February, JinkoSolar signed a solar-glass procurement contract with Flat Glass Group Co., which secured around 338 million square metres of rolled glass to support the production of 59 GW of JinkoSolar modules from 2021 to 2023.

In other news released with JinkoSolar’s annual results, Li said the company is developing energy storage products specifically designed for the US and Japanese markets, and that its “Building Integrated Photovoltaics (BIPV) systems have been installed in a number of commercial real estate projects in China”.

Its latest BIPV project is a carport for 40 electric vehicles, which was connected to the grid in China in January. JinkoSolar’s BIPV products replace the traditional roof of the carport and feed electricity into charging pylons, with an annual generation capacity of more than 150,000kWh.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

2 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.