The investigation into the fire which broke out during the commissioning of Australia’s biggest battery has today had its findings released, with the most likely root cause deemed to be a leak within its Tesla Megapack cooling system.

One of the largest battery energy storage systems in the world, the fire at the Neoen-owned 300 MW / 450 MWh Victorian Big Battery unsurprisingly led to renewed global discussions around the safety of lithium-ion battery technologies.

Investigation findings

The multi-party independent investigation into the fire uncovered that the system in place to detect faults didn’t set off alarms because it hadn’t been given adequate time to ‘map’ the control system, which generally takes around 24 hours.

The Megapack which caught fire had been switched to offline mode after just 13 hours in service, meaning the protection systems which should have been operating and providing oversight did not do so.

In its Statement of Technical Findings published this morning, Energy Safe Victoria said: “the cause of the fire was identified as coinciding short circuits in two particular locations likely initiated by a coolant leak external to the battery compartment… Enabled by this unlikely sequence of events the fault was able to go undetected and initiate a fire in the adjacent battery compartment.”

“Mitigating actions have been put in place at the facility and across Tesla’s global Megapack fleet, including a combination of firmware enhancements, as well as monitoring and process improvements,” Energy Safe Victoria’s statement read. You can find the list of those actions at the end of this article.

Image: Neoen

Following the conclusion of the investigations, which additionally involved the Country Fire Authority, WorkSafe Victoria, and the Environment Protection Authority, regulatory authorities have provided Neoen and Tesla with approval to resume energisation testing from tomorrow, September 29.

Full report slated for November

Energy Safe Victoria said in its statement that learnings from the event are currently being compiled by two independent expert groups, Energy Safety Response Group & Fisher Engineering, with an Independent Report to be released by November. “Information and insights, including lessons for fire management and emergency response, will be publicly shared to support the industry and relevant authorities in the deployment of battery storage technology.”

“We have taken the time to understand the cause of the incident and we have implemented actions to ensure it will not happen again,” Louis de Sambucy, Neoen Australia’s Managing Director said. “We are now actively working with all stakeholders to complete commissioning and testing of the project and we look forward to sharing the lessons learnt with the industry in coming weeks.”

Image: CFA

Prompted by the Victorian fire, the issue of large-scale battery performance and safety is also the topic of pv magazine’s upcoming Insight Australia event, which which will include a case study of the event.

Fire recap

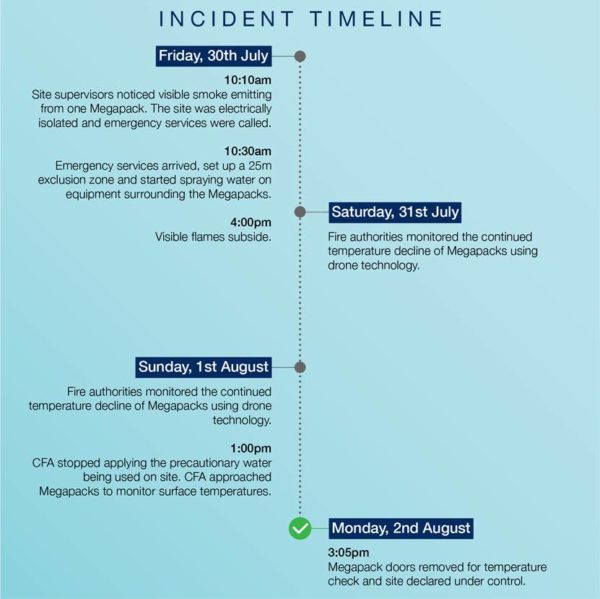

It was around 10:30am on July 30 when 150 firefighters responded to a fire at the site of Victoria Big Battery being developed near the Moorabool Terminal Station at Geelong. Fire crews arrived to a 13-tonne lithium battery ablaze in a shipping container, which wasn’t brought under control until the afternoon of Monday August 2, three days later.

The fire destroyed two of the project’s 212 Tesla Megapacks.

Originally slated for completion by November, Neoen said today it is still aiming for the battery to be operational in time for Australia’s summer, typically the period of highest grid demand.

In November 2020, AEMO in fact awarded the Victorian Big Battery a 10-year contract under the System Integrity Protection Scheme, which will require the battery’s operators to reserve 250 MW of its capacity to participate in increasing the capability of the Victoria-to-New South Wales Interconnector (VNI) and respond to unexpected network outages.

Neoen taken to court over Hornsdale Power Reserve

Neoen could be considered a preeminent force in Australia’s push for grid-scale battery storage projects, with the company recently securing tenders for the first stage of the Goyder South project in South Australia and a big battery in Canberra. The French firm also owns the soon-to-be commissioned 20 MW/ 34 MWh Bulgana green power hub in north west Victoria, and of course the project which brought its preeminence, the Hornsdale Power Reserve, better known as the South Australian Tesla Big Battery.

Be that as it may, the recent fire wasn’t the only heat the French developer has been feeling.

Photo: AECOM / Neoen Australia

Just last Friday, the Australian Energy Regulator (AER) instituted proceedings in the federal court against the company in regard to its 150 MW/194 MWh Hornsdale Power Reserve (HPR) for alleged breaches of the National Electricity Rules. The AER claimed Neoen’s South Australian facility did not provide the frequency control services it was paid for.

“Between July and November 2019, HPR made offers to the Australian Energy Market Operator (AEMO) and was paid to provide market ancillary services which allegedly it could not in fact provide, including when required to provide those services after a frequency disturbance,” the AER said in a statement.

The AER is seeking pecuniary penalties, declarations and costs.

Neoen Australia’s MD Sambucy has chosen not to comment on the specific allegations but in a brief statement said HPR had repeatedly delivered on high expectations since opening for business in 2017, in terms of “its performance and market impact, positively impacting ancillary service prices and proving itself to be a critical component of the South Australian electricity network”.

“Whilst we are disappointed by the AER decision, we will continue to maintain our collaborative relationship with them,” he said.

List of the actions now to be taken

In regard to the Victorian Big Battery fire, the following actions have been enforced:

- Each Megapack cooling system is to be fully functionally and pressure tested when installed on site and before it is put into service

- Each Megapack cooling system in its entirety is to be physically inspected for leaks after it has been functionally and pressure tested on site

- The SCADA system has been modified such that it now ‘maps’ in one hour and this is to be verified before power flow is enabled to ensure real-time data is available to operators

- A new ‘battery module isolation loss’ alarm has been added to the firmware; this modification also automatically removes the battery module from service until the alarm is investigated

- Changes have been made to the procedure for the usage of the key lock for Megapacks during commissioning and operation to ensure the telemetry system is operational

- The high voltage controller (HVC) that operates the pyrotechnic fuse remains in service when the key lock is isolated

Designers are also working to ensure that Megapacks are engineered to fully mitigate the risk of fire propagation from one unit to another under Victorian climatic conditions, with proposed mitigation procedures to be rolled out to applicable Megapacks globally.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.