From pv magazine Global

To guide the development of faster-charging and longer-lasting batteries, scientists need to be able to understand the processes occurring inside of an operating battery and identify the limitations to its performance.

Currently, sophisticated synchrotron X-ray or electron microscopy are the most often used techniques in visualising active battery materials. However, they can be complicated and expensive, and not quick enough to capture the rapid changes happening in electrode materials.

Now, researchers at the University of Cambridge have applied a low-cost, laboratory-based optical microscopy method to study micrometer-sized rod-like particles of one of the fastest charging anode material today (Nb14W3O44) during high-rate cycling. They described their method in “Operando monitoring of single-particle kinetic state-of-charge heterogeneities and cracking in high-rate Li-ion anodes,” which was recently published in Nature Materials.

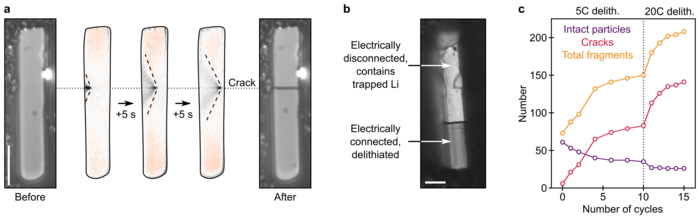

First, visible light was sent into the battery through a small glass window, allowing the researchers to watch the dynamic process within the active particles, in real time, under realistic non-equilibrium conditions. This revealed front-like lithium-concentration gradients moving through the individual active particles, resulting in internal strain which caused some particles to fracture. Particle fracture is a problem in batteries, as it can lead to electrical disconnection of the fragments, reducing the storage capacity of the battery.

“Such spontaneous events have severe implications for the battery but could never be observed in real time before now,” said researcher Christoph Schnedermann, from Cambridge’s Cavendish Laboratory.

The optical microscopy technique allowed the researchers to analyse a large population of particles. This revealed that particle cracking is more common with higher rates of delithiation and in longer particles.

“These findings provide directly-applicable design principles to reduce particle fracture and capacity fade in this class of materials” said researcher Alice Merryweather, a PhD candidate in Cambridge’s Cavendish Laboratory and Chemistry Department.

In addition to the rapid data acquisition, single-particle resolution, and high throughput capabilities, the novel technique is expected to facilitate further exploration of what happens when batteries fail and how to prevent it. It could also play a role in the development of next-generation batteries, as it can be used to study almost any type of battery material.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.