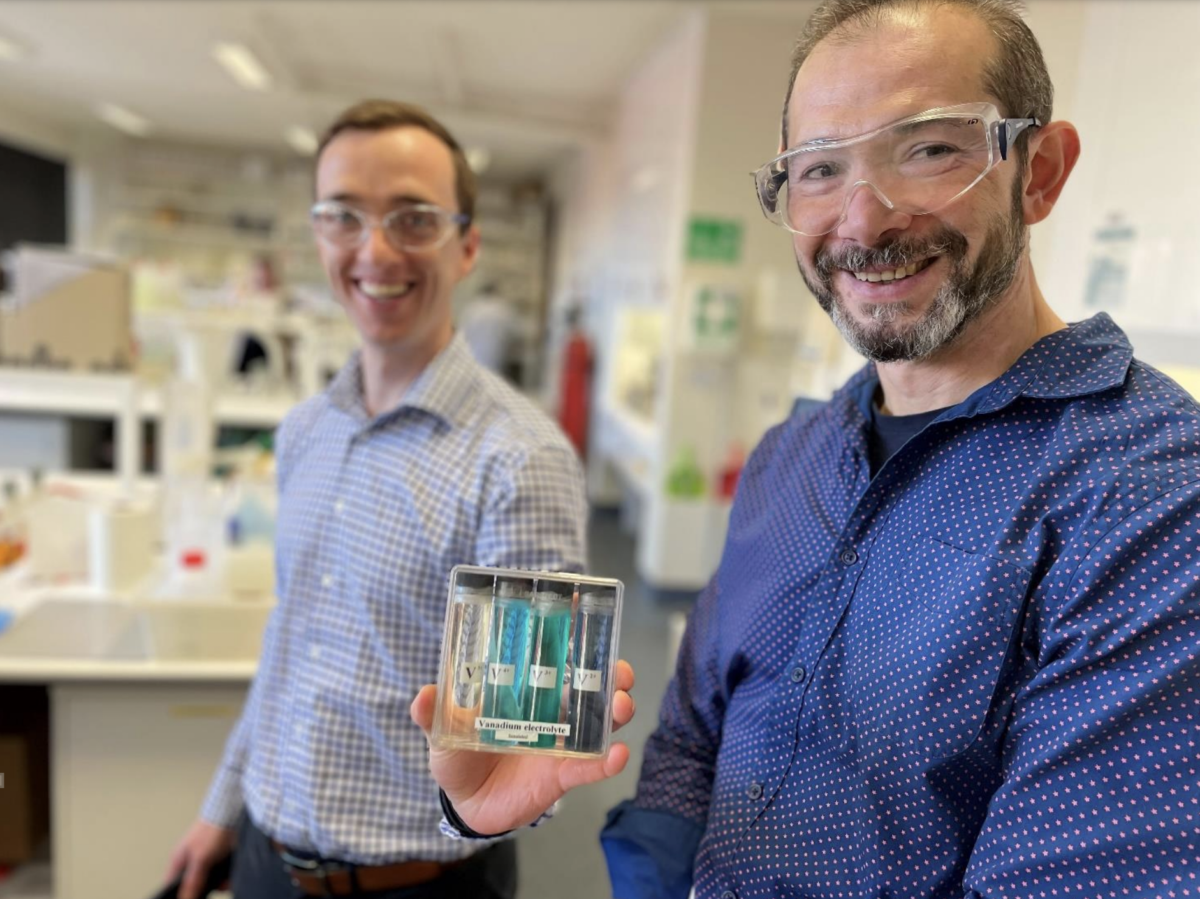

West Australian vanadium explorer Technology Metals Australia (TMT) will embark on a three year research program into electrolytes with the Future Battery Industries Cooperative Research Centre.

Alongside being the largest shareholder in the program, TMT will be supplying product from its Murchison Technology Metals Project as feedstock for the vanadium redox flow battery focussed research. Those feedstocks, the company says, includes magnetite concentrate and vanadium pentoxide.

Through its subsidiary vLYTE, the company hopes to eventually leverage the project’s findings, adding value to its own resources.

The study will involve experimenting with additives and stabilising agents and measure the effect of impurities to ultimately determine the optimal concentrations for VRFB electrolyte.

The majority of the research is set to be completed at Murdoch University in Western Australia.

ASX-listed company TMT is currently focusing on a processing technique to produce high purity vanadium pentoxide. The company’s goal is to become one of the world’s largest single primary vanadium producers, catering to the expanding flow battery market.

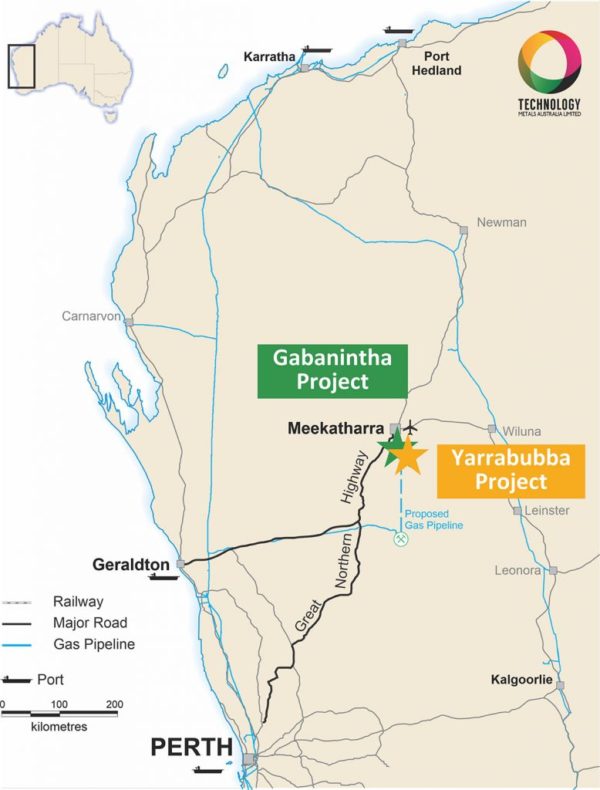

In terms of projects, the company appears to have rolled both its Gabanintha and Yarrabubba vanadium projects into one umbrella it is referring to as Murchison Technology Metals Project. The project will involve both a mine and a processing facility.

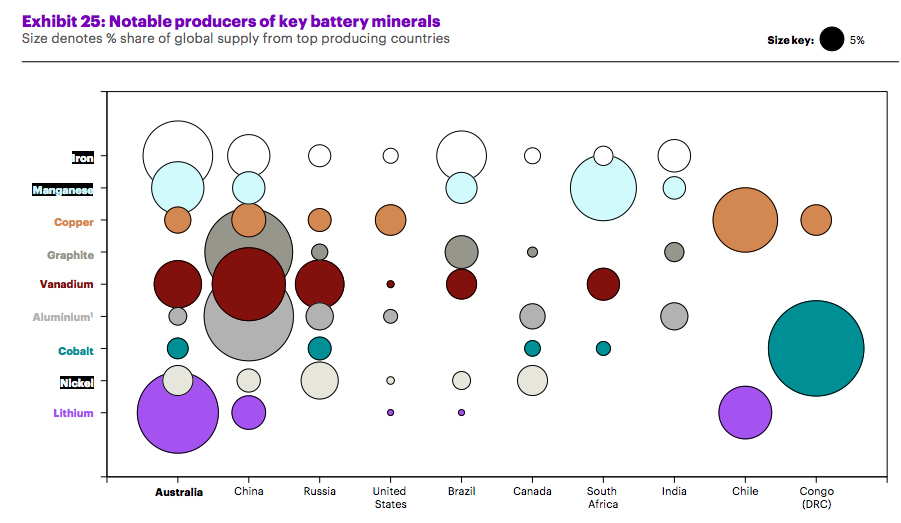

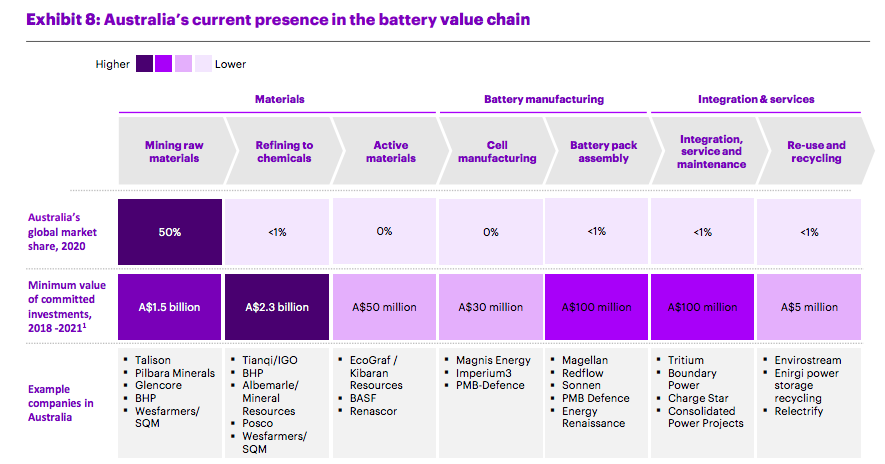

Teaming up with the Future Battery Industries Cooperative Research Centre seems a natural fit then as the government backed agency has long advocated Australia expand its onshore battery material processing capacity. It argues this is by far the best way for the country to capture the value presented by its large reserves of battery minerals like vanadium.

“By 2050, in a net-zero scenario, 70% of all renewable spend will be on batteries,” Future Battery Industries CEO Shannon O’Rouke said.

“Vanadium batteries are compact, durable, and infinitely recyclable, making them excellent for long-duration storage.

“The technology was invented in Australia, and we’re pleased to be looking at ways to lower costs and improve quality.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.