Aspiring vanadium redox flow battery (VFRB) manufacturer AVESS is the latest in a string of Australian players entering the vanadium battery sector and is hoping manufacture flow batteries onshore in the coming years.

AVESS owns 50% of South Korean vanadium redox flow battery (VRFB) company Korid Energy, and it is this battery technology and design AVESS is seeking to bring to Down Under.

To that end, the company will be deploying two demonstration batteries at an edge-of-grid mine in Western Australia, one with a capacity of 50 kW / 250 kWh and another 25 kW / 250 kWh – giving them five and 10 hours of storage duration respectively.

“This year is all about proving our VRFB batteries,” Managing Director Young Yu tells pv magazine Australia. Specifically, the company is seeking to demonstrate its VRFB technology’s improved efficiencies and low storage cost in actual Australian conditions.

“We need to localise our product and technology,” Yu says, “and that is what we are doing in July and August.”

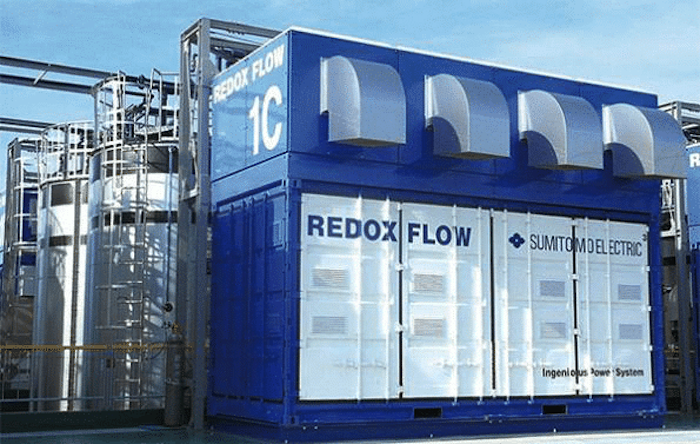

Image: AVESS

Once that box is ticked, Yu says AVESS will look to raise $15 million (USD 10.2 million) from “cornerstone investors” to roll out its Australian manufacturing plan. The aim is to start this from 2024, with the company allocating three years to set up the capacity so that it can be manufacturing or assembling VRFBs from 2027.

Too early to give exact details on scale, Yu says the ambition is to be producing “quite a significant amount” of megawatt hours. Western Australia is the obvious choice for the manufacturing plant – though Yu says other states are also being considered.

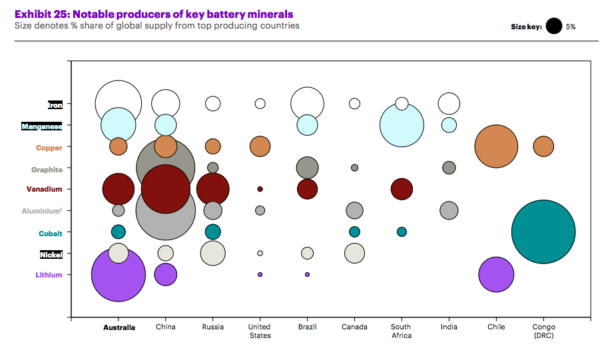

“It makes huge sense for us to set up a [manufacturing] operation here because of [Australia’s] mining capabilities in the vanadium industry sector. We see huge resources captive here in the Australian market we can take advantage of,” Yu says, pointing out that Australia’s abundance of vanadium also makes it a strong candidate to produce vanadium electrolytes.

To that end, AVESS recently signed a deal to partner with South Korea’s Unicoh Specialty Chemicals to explore the development of electrolyte manufacturing for VRFBs. “Ultimately, we want to bring that know-how to Australia and work with Australian mining companies to produce electrolytes here.”

Demonstration batteries

The name of the mining company deploying the two demonstration batteries has not yet been made public, but Yu says the discussions are close to being finalised.

The first cab off the demonstrative rank will be the 50 kW VRFB – currently under construction. Continuum Engineering has been hired to help design and develop the Perth battery.

It is expected to be fully assembled by Q2 and ready to be deployed in Q3 to a to-be-confirmed mine site.

The demonstration seeks to measure arbitrage capability in a solar/grid connection and benchmark a levelised cost of storage (LCOS). “This exercise will aid in validating our proprietary technology in Australia, and the data obtained from the study will be key as AVESS works towards the Australian Renewable Energy Agency set target of $0.10 per kWh LCOS by 2030,” the company has said.

AVESS’ VRFB technology, developed in South Korea by subsidiary Korid, claims to have improved efficiency rates from the industry norm. “Our levelised cost of storage we’ve compared to other companies and we know we are performing really well,” Yu adds.

These figures, however, come from projects and tests in South Korea, and AVESS is keen to prove they hold true in Australia.

The company is also planning a second, longer duration demonstration battery, potentially at the same mine site – though this remains unconfirmed. Korid Energy is delivering this second battery, with Yu saying the subsidiary is in the final stages of assembly. He expects it will be shipped to AVESS next quarter.

VRFBs

Vanadium redox flow batteries were invented in Australia in the 1980s but remain quite novel. Yu believes this novelty, and the perceived risks that go with it, are finally subsiding. Both the advantages and disadvantages of flow batteries are becoming better known and accepted, he says. “I think industry is seeing that and looking to give vanadium a go.”

Joining in a much larger zeitgeist, he says a core driver for AVESS is to be a wholly Australian-owned company producing Australian-made tech, and with that bringing manufacturing back onshore. In short, the company is looking to be part of the “Make Australia Make” movement that has gripped renewable industries.

Image: Future Battery Industries Cooperative Research Centre

Yu says AVESS is currently speaking to state governments and regional stakeholders about potential sites for manufacturing. Given the vast majority of vanadium projects and companies are based in Western Australia, the state is a top contender – though Yu points out Queensland is also emerging as another vanadium hub.

By 2027, the company is hoping to have roughly 200 staff on board. It is seeking to cater to the Australian market, as well as potentially exporting its VRFBs in future.

Collaborating with vanadium miners

Naturally, vanadium miners will form an integral part of AVESS’ supply chain. “We do have a very keen interest in development plans,” Yu says. “We have been communicating with a couple of vanadium producers, or want-to-be producers… and are trying to share our vision to see how we can collaborate.”

The hope is that eventually AVESS will be able to source its electrolyte from Australian suppliers – but until that day comes, Yu says the company will need to rely on China, which currently dominates the vanadium electrolyte industry.

This dominance is what drove AVESS to set up a joint venture with Unicoh Specialty Chemicals, Yu says. The company recently signed a non-binding memorandum of understanding (MoU) with the South Korean chemical specialists to look into vanadium electrolyte production.

Yu says the company eventually wants to produce its own electrolyte here in Australia in collaboration with a local vanadium miner. Such a collaboration would help AVESS establish a vertically integrated supply chain, something Yu deems “very very important.”

“We think vanadium is a critical mineral which needs to be managed properly and we really don’t want one nation in the world actually dominating this particular sector,” he says, referring to China.

“This is a requirement for us to work together in the Australian market to assist the Australian vanadium miners to actually start producing as soon as possible,” he adds.

Like the United States, Yu says South Korea is increasingly turning to Australia to supply key materials and components for its booming battery industries. “Korea is looking at Australia for strong partnership,” Yu says, especially when it comes to critical minerals like vanadium.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.