Graphite is a key component in battery anode material, which is ultimately responsible for holding and distributing charge in lithium-ion batteries. The overwhelming majority of processed graphite today comes from China – a situation some Australian companies are trying to shift.

And shift it they might, with a recent scoping study finding International Graphite’s proposed processing plant in the West Australian town of Collie could provide initial returns of between 41% to 48%.

Scoping Collie’s Graphite Battery Anode Material Facility

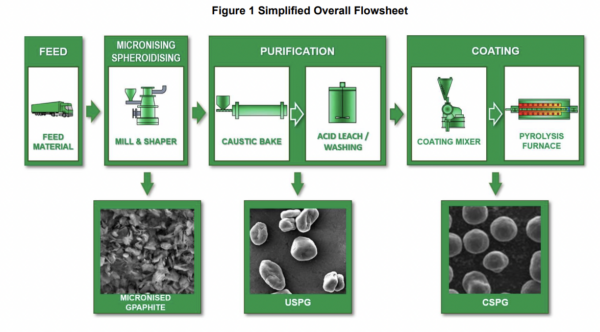

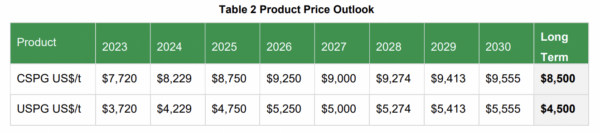

As it stands, International Graphite is proposing to build its Collie Graphite Battery Anode Material (BAM) Facility in a modular fashion so that it can be completed in stages. The current flowsheet will see the company micronising, spheroidising and chemically purifying graphite to first produce uncoated spheroidised purified graphite (USPG). This first USPG facility would then be expanded to involve carbon coating, ultimately producing coated spheroidised purified graphite (CSPG).

The company forecasts the total capital cost to realise the USPG plant is approximately USD 87 million ($131 million) while its operations are forecast to deliver a pre-tax net present value of approximately USD 290 million ($440 million). This equates to an internal rate of return of 48%, the company said.

The total capital cost to realise the later stage coating plant is approximately USD 222 million ($336 million) and its operations are forecast to deliver a net present value of approximately USD 626 million ($947 million), for a return of approximately 41%.

“The economics are outstanding and there are many opportunities to improve the cost structure with further testwork,” CEO Worland said.

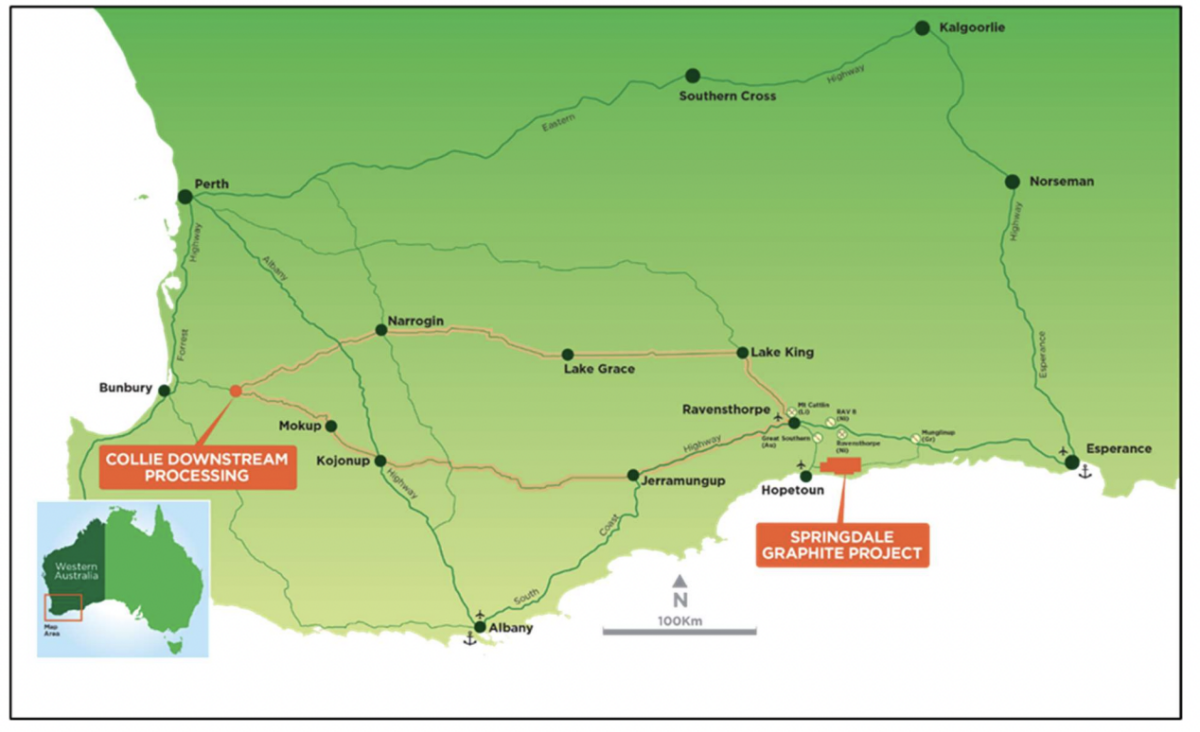

This scoping study was based on International Graphite purchasing graphite concentrates from third party sources. In 2022, however, the company finalised its acquisition of the Springdale Graphite Project, a natural graphite mine roughly 450km from Collie.

The company is ultimately planning to vertically integrate its business and use the output from the Springdale Graphite Project as the feedstock for the Collie downstream processing plant. “When we have advanced Springdale to a sufficient level of detail to allow forecasts to be published, we will be able to update the Scoping Study accordingly,” International Graphite’s Managing Director and CEO Andrew Worland said.

Next steps

Buoyed by the promising results, International Graphite said: “We are working with a number of stakeholders in Collie to agree on site selection for the Collie Graphite BAM Facility to accommodate the initial graphite concentrate processing capacity of up to 40kt/y and potential further expansions.”

Collie is home to Western Australia’s soon-to-be retiring coal plants and the state government is pouring money into the region to help reposition it to become a clean energy centre. Former CEO of International Graphite, Neil Rinaldi, previously told pv magazine Australia it had chosen Collie for its processing plant on the promise of extremely cheap, green power.

International Graphite aims to have a definitive feasibility study for the Collie Graphite BAM Facility in the third quarter of 2024. “A final investment decision would be undertaken at the point at which the company considers it is suitably funded,” the company added.

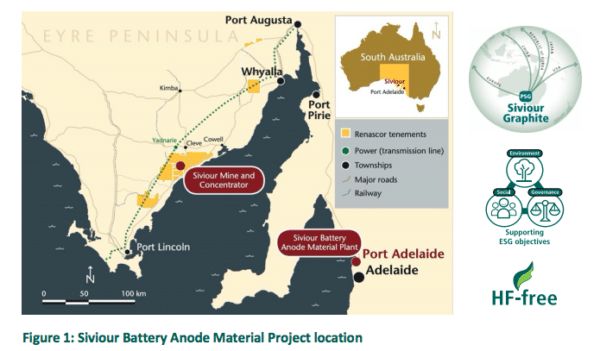

International Graphite is not the only Australian company looking to become a BAM producer outside of China – South Australian company Renascor Resources is rapidly progressing its plans. It too is pursuing a vertically integrated business model, developing both a graphite mine and manufacturing facility in South Australia.

On Wednesday, it announced it is in the advanced stages of an updated and optimised Battery Anode Material Study to assess increasing the ambition and acceleration of its proposed Siviour Battery Anode Material Project. The move comes after Renascor received environmental approval from the government of South Australia for the project late last year.

Renascor Resources

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.