Data from the International Energy Agency (IEA) shows the world added nearly 510 GW of renewable energy capacity in 2023 – a 50% increase on 2022. The agency has predicted that global renewable capacity will reach 7,300 GW by 2028, driving massive demand for of clean energy technologies including solar panels, wind turbines, and battery energy storage systems.

A panel of industry experts convened on day one of the Smart Energy Expo in Sydney acknowledged the scale of the transition from coal-dominated to renewables-dominated generation presents enormous opportunities for an Australian manufacturing industry.

Tindo Solar Chief Executive Richard Petterson however said it is critical Australia moves quickly to ensure it shares in the benefits of the energy transition by “creating hundreds of jobs and a domestic renewables manufacturing industry.”

“There’s a lot of talk about what the country should do,” he said. “But everyone else is getting on with it. Anyone that’s really in this race is already halfway down the track. We’re the last cab off the rank.”

Tindo earlier this year revealed it intends to expand its solar energy manufacturing capacity, announcing plans to build a $100 million factory that would deliver a six-fold increase in its capacity.

The new plant, likely to be located on the east coast of Australia, is expected to commence production in 2025 and be able to manufacture about 2.5 million panels per year – equivalent to approximately 1 GW of capacity per annum.

The existing Tindo manufacturing facility at Mawson Lakes in northern Adelaide has an annual capacity of 360,000 panels, equivalent to 150 MW per year.

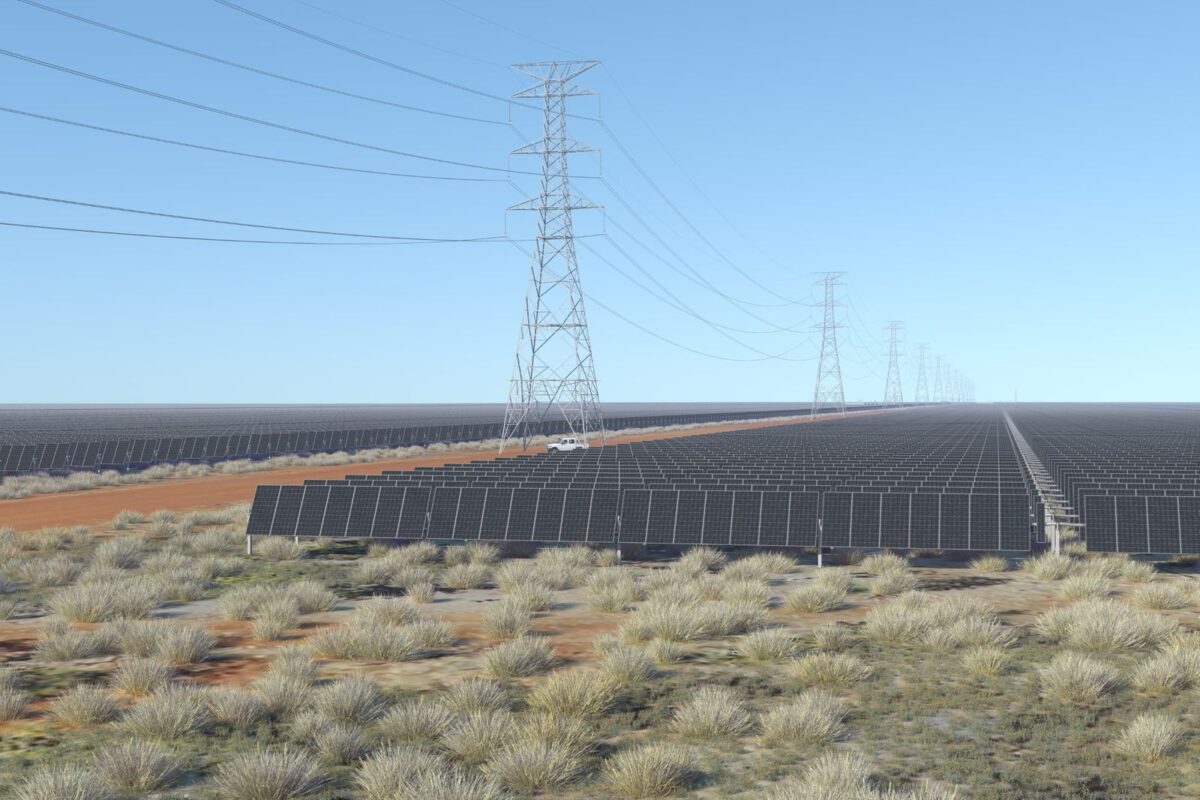

Image: pv magazine

Petterson believes the establishment of a gigascale facility, and the associated demand for components, will help build up and support a local supply chain.

“If we get the conditions right, if the government gets the conditions right, 1 GW should be large enough to start drawing a supply chain that makes a bit of a difference,” he said.

“We’ll start to stimulate other parts of our supply chain. At the moment, our draw through is quite small.”

The chief commercial officer at Australian solar innovator SunDrive, Dr Maia Schweizer, told the audience it will take “time, commitment and grit” for Australia to establish a clean energy manufacturing sector of note.

Schweizer said Australia’s ambition to build a solar manufacturing industry is battling a 10c to 15c per Watt headwind relative to Chinese products, a disadvantage driven mostly by labour costs and the higher capital cost of facilities but added there is reason to be optimistic.

“We’ve done modelling that shows with greater automation, with cheap, plentiful green energy, and by translating [Australia’s] intellectual legacy into the commercialization of technology, we think we can close the gap in the coming decade,” she said.

Image: pv magazine

Schweizer listed three objectives she believes are necessary for the development of a domestic clean energy manufacturing sector.

“The first is to buy Australian,” she said. “Give Australian manufacturers some sense that they can compete for a market.”

“The second thing is to help bridge the structural headwinds.”

“While encouraging the innovation and automation and the large-scale deployment of low-cost green power will inevitably turn those headwinds into tailwinds, we do need support until that happens and that could be a five-to-10-year journey.”

Schweizer’s third objective is to play to the nation’s intellectual strength, pointing to the work of Professor Martin Green, who is widely considered the father of PV, having led the research team at the University of New South Wales that took PV out of the lab and into the market.

“Australia is a world-renowned source of solar excellence, so let’s try to keep some of that here,” Schweizer said.

SunDrive’s own manufacturing ambitions remain on track with the Sydney-based startup opening a 20 MW pilot line at its nearly 5,000 square metre facility at Kurnell.

Schweizer said the next step for the company, which successfully replaced the silver traditionally used in solar cells with copper, is to “build a commercial-scale facility to bring hundreds of MW a year of our world-leading solar cells to the market from mid-2025.”

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

3 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.