Fortescue’s climate transition plan outlines comprehensive details of how the mining giant is, and will 100% eliminate fossil fuels from their Australian iron ore operations by 2030 using a number of measures, including solar energy.

The plan states Fortescue’s belief is that all business should follow their example in committing to a date when they will no longer rely on fuels that cause catastrophic climate change.

Fortescue Executive Chairman Dr Andrew Forrest released the action plan at a roundtable event hosted by UN Under-Secretary General Melissa Fleming in New York with a detailed timeline of how Fortescue will eliminate Scope 1 and 2 emissions without voluntary carbon offsets or carbon capture and storage.

“Net Zero 2050 is a con. The world needs Real Zero now. Fortescue can tell you when we’ll eliminate fossil fuels and show you exactly how. Every industrialist should match us,” Forrest said.

“Companies that set emissions reductions targets must demonstrate how they will deliver them. Only when we hold ourselves accountable for our commitments do we earn our seat at the table.”

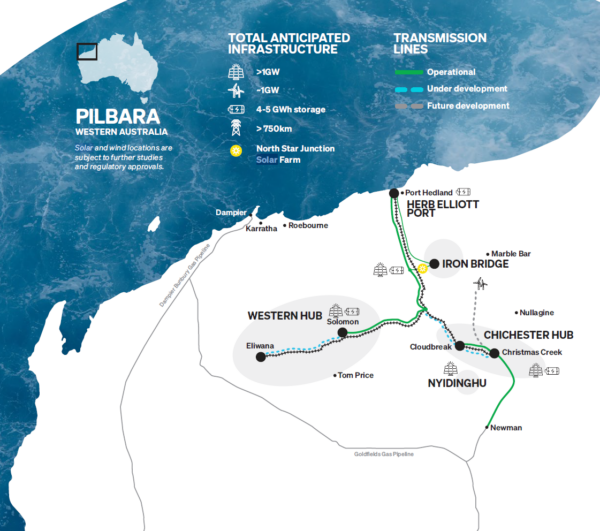

Among numerous measures including the Gladstone Electrolyser Facility (GEF) in Queensland, the company’s decarbonisation roadmap includes in 2024, completion of commissioning of the North Star Junction 100 MW / 250 GWh per annum solar farm, which represent 30% of forecast FY25 energy demand at the Pilbara Iron Bridge mine site.

North Star Junction compliments a 60 MW solar farm commissioned in 2021 as part of the Chichester solar gas hybrid facility.

North Star Junction is anticipated to be fully commissioned in 2025 and during that year new solar and battery energy storage systems (BESS) are to commence construction, along with accommodation for the workforce required to build them, and fast chargers and electrical reticulation to support zero emissions haul trucks and other heavy mobile equipment (HME).

Modelling investigations on how best to optimise the Pilbara iron ore operations when powered by renewable energy show an additional 2-3 GW of renewable energy and BESS is required to decarbonise.

Fortescue

To achieve this, the company’s board has approved significant capital investment to fund multiple green power projects including utility scale solar at Cloudbreak, utility scale batteries at North Star Junction and Eliwana, and high voltage electrical 750 kilometre transmission infrastructure to connect the mine sites to form an interconnected energy system across operational sites.

The first fully electrified site is planned for 2027, supported by operational solar and BESS, with demand response and energy efficiency solutions integrated as standard, and by 2030, solar and wind, supported by BESS will power all of Fortescue’s Australian mining operations, eliminating diesel and other fossil fuels.

Other initiatives include battery-electric light vehicle trials, mainline rail trials of an ammonia-fuelled locomotive and hydrogen fuel cell haul truck testing in Perth and on iron ore mine sites.

In 2025, trials will begin on a battery-electric locomotive – the Inifity Train – in partnership with Sydney-based civil engineering group Downer, plus construction of Fortescue’s first BESS will begin, with prototype operational battery-electric haul trucks onsite.

In 2026, heavy mobile fast chargers will be installed onsite, the use of electric drills will be implemented, and the first zero-emission haul trucks will arrive, which are being developed in partnership with Swiss industrial equipment manufacturer, Liebherr.

Zero emissions drills will arrive in 2027, and between 2029 and 2030 a renewable energy grid will be fully integrated marking the full decarbonisation of Fortescue Australia’s iron ore terrestrial operations.

In addition to wind, solar and battery projects, Fortescue has started constructing the onsite electrical reticulation infrastructure that will take the energy from the Pilbara Energy Connect (PEC) transmission infrastructure to where it is needed on site.

The PEC project aims to integrate Pilbara mining and port operations into one common 220 kV network. This program of works will continue through FY24 to FY28 to enable sites to have the electrical infrastructure ready to power the electrical equipment, as it becomes operational.

In shipping, which represents 13% of the company’s FY24 Scope 1 emissions, Fortescue is continuing to retrofit of energy saving devices to their fleet of very large ore carriers and investigate the viability of converting them to run on green ammonia.

Their tug boat fleet will become battery-hybrid vessels charged by solar and wind power and generation onboard from a green fuel.

Developing trials and integrating battery-electric haul trucks and other HME addresses 51% of Scope 1 emissions from HME and will be eliminated through measures such as electrifying sites to eliminate diesel and gas, use green hydrogen fuel cells, and powering HME from renewable generation using trailing cables.

Scope 2 emissions will be 100% eliminated through purchased energy via renewable power purchase agreements and Fortescue is engaging with power providers to progress renewable energy development.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.