JA Solar test reveals n-type panels outperform p-type counterparts

Chinese manufacturer JA Solar said that tests have shown that n-type modules have a 3.9% higher power yield than their p-type counterparts. Germany-headquartered technical service provider TÜV Nord has confirmed the results.

Behind-the-scenes look at solar panel production shines light on Australian manufacturing

With the International Energy Agency leading calls to diversify the world’s solar PV supply chain, Australia’s only solar panel maker Tindo Solar has released a video following the manufacturing process at its new $11 million production facility in Adelaide.

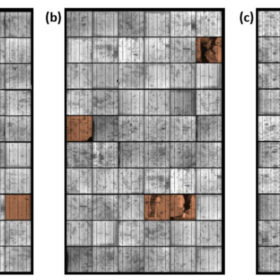

Small cracks have negligible effect on solar cell performance

A team of researchers from the United Kingdom have found that crack percentages of up to 11% have a very limited impact on solar cell performance. They also ascertained that hotspots are likely to arise when the crack percentage is in the range of 11 to 34%.

Novel method to turn existing solar parks into agrivoltaic facilities

An international research team has developed a new methodology to increase levels of pollination at ground-mounted solar plants. It involves the development of new vegetated land cover below and around solar parks.

Tesla reveals surging Powerwall numbers as it gears up to double EV sales

Tesla chair Robyn Denholm expects the company to double its EV sales in Australia by the year’s end, hoping to see its flagship product catch up to its Powerwall sales. Denholm also said Australia needs to expand its lithium refining and processing capacity at “sprinting pace” to properly capture the global battery opportunity.

New method to evaluate performance, LCOE of elevated agrivoltaics

Scientists in Belgium have developed a way to assess elevated agrivoltaic projects, by calculating key performance indicators such as energy yield and levelized cost of energy (LCOE). They have found that shade-tolerant crops such as potatoes could potentially be paired with around 1,290 GW of PV capacity in Europe.

Solar power costs continued to fall in 2021, despite rising panel prices

The average global price of solar kilowatt-hours fell 13% on 2020’s prices, as around two-thirds of the renewables capacity installed last year was cheaper than the lowest-cost fossil fuel alternative.

Australia & US sign energy agreements to mitigate China over-reliance, ensure supply chains cannot be weaponised

Speaking at the Sydney Energy Forum, leaders from Australia and the US have highlighted the importance of not only transitioning to renewables, but of ensuring the supply chains used to make the technologies do not remain as concentrated as they are today.

GE turns to Australia for critical renewable materials

US giant General Electric (GE) has signed an agreement with Australia’s Arafura Resources, provisionally agreeing to offtake from the company’s flagship Nolans Project in the Northern Territory, which is aiming to become a major supplier of critical materials for wind turbines and electric vehicles.

Heat pumps ‘grossly underestimated’ technology for Australia’s decarbonisation

Interest and investment in heat pumps has surged in Europe, but in Australia the technology has struggled to find a serious foothold. Industrial heat pumps could reduce ‘hard to abate’ emissions here by 15 million tonnes per annum by 2050, according to new modelling from the Australian Alliance for Energy Productivity though. Despite the potential, dodgy technology suppliers and schemes gone awry have left a bad taste in Australia’s mouth, CEO Jarrod Leak tells pv magazine Australia.