New tool to understand component failure rate in PV-related fires

Scientists have developed a new model based on fault tree analysis to evaluate the frequency of fires caused by rooftop PV systems and assess system safety and reliability. They claim that the new tool has the potential to identify fault linkages in systems, highlight failure patterns before they arise, and compare multiple designs for safety.

New tank design promises to significantly improve the reliability of thermal energy storage

A consortium including Australian concentrated solar thermal power company Vast Solar has filed to patent a new tank design for thermal energy storage systems. The new design, it says, substantially mitigates the risk of tank failures which have been identified as one of the key shortcomings of the economical storage technology.

5B acquires Adelaide manufacturing plant ahead of global gigawatt-scale push

Sydney-based solar pioneer 5B has today announced it will acquire IXL Solar’s Adelaide-based manufacturing business, with pv magazine Australia told the purchase will see 5B buy everything but the name, effective immediately.

Photovoltaic rotary energy system for domestic applications, high-rise buildings

Developed by scientists in Turkey, a system prototype has operated at lower PV module temperatures and removed most of the dust accumulation. The researchers are now planning to improve the device by applying maximum power point tracking (MPPT) converter topologies.

$2.4 billion battery minerals complex granted major project status

The way has been smoothed for Australian mining company Sunrise Energy Metals to take advantage of the booming lithium-ion battery industry with the federal government awarding Major Project Status to a $2.4 billion nickel and cobalt mine being developed in New South Wales.

Jinko reduced module prices in the third quarter

The Chinese manufacturer appears to have shouldered higher input costs in return for carving out a larger slice of the world’s biggest solar market – although it’s not clear from the company’s third-quarter update that CEO Xiande Li received the memo.

Sonnen launches residential battery specifically designed for Australia, marking shift in global strategy

German company sonnen, a wholly owned subsidiary of Shell, today launched a new residential battery storage system specifically developed for Australia and New Zealand. Chief Commercial Officer of sonnenGroup and Managing Director of sonnen Australia, Nathan Dunn, told pv magazine Australia its sonnenBatterie Evo is the culmination of a new approach and may go on to inform how its future products for global markets are developed.

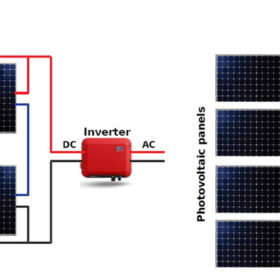

Micro-inverters vs. string inverters

A French research group has compared the performance ratio of 100 PV systems relying on micro-inverters with that of 100 installations relying on string/central inverters. It found the performance ratio is around 79% for both system typologies and that arrays with micro-inverters are more sensitive to environmental factors.

Grid-forming big battery breaks ground in South Australia

AGL has “broken ground” at Torrens Island power station in preparation for the construction of its 250 MW/250 MWh battery which has drawn interest for being the largest planned grid-forming battery in the world.

Behind the price drops in lithium-ion batteries

Scientists in the United States pieced together data from hundreds of different sources, looking to establish the key factors that have led to consistently falling prices for lithium-ion technology since their commercialisation thirty years ago. They find that public-funded research, primarily in chemistry and materials science, has made the largest contribution to cost reduction. And they offer suggestions on policy and investment to ensure that the research can continue to make these important contributions to reduction in battery costs.