Australia singled out as key investment market for Asian majors

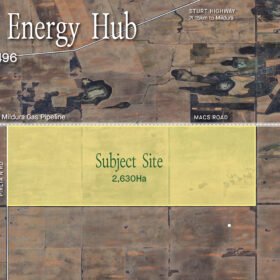

Executives from Gentari, the clean energy subsidiary of Malaysia’s state-owned oil company Petronas, and Japan’s biggest steelmaker, Nippon Steel, are eying Australia for future investments in renewables projects and green-steel manufacturing.

South Australian miner to lodge application for critical rare earth mine

Australian mining company Australian Rare Earths is moving forward with plans to apply for a licence to mine rare earths in South Australia’s southeast as part of its flagship Koppamurra project.

Queensland’s $5 billion CopperString purchase to unlock 6 GW of renewables

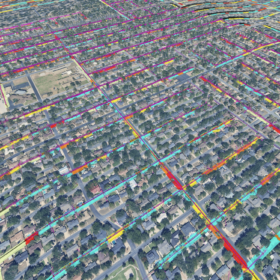

The Queensland government will acquire the $5 billion (USD 3.37 billion) CopperString transmission line project which is set to unlock 6 GW of renewable energy resources and connect Queensland’s North West Minerals Province to Australia’s national grid. The shovel-ready project, many years in the making, is hailed as the biggest expansion to Australia’s energy grid in decades.

BayWa re to sell PV product distribution business

BayWa AG is strategically realigning BayWa re so it can sell its solar trade business. In the future, the subsidiary will focus on international projects as an independent power producer (IPP).

Aussie startup launches battery electrolyte pilot manufacturing line

Allegro Energy, an Australian startup seeking to commercialise research into microemulsions to make non-toxic electrolytes that are cheaper “by factor of 100,” has commissioned a pilot-scale manufacturing line for supercapacitors in Newcastle, NSW.

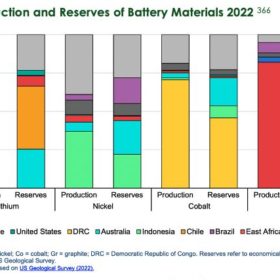

Australia’s critical minerals pipeline valuated at $10 billion

A report from consultancy Climate Energy Finance finds that Australia and New Zealand have a more than $10 billion (USD 6.7 billion) pipeline of investment proposals in resource value-adding critical minerals, including in lithium, nickel, cobalt, vanadium, rare earths, hydrogen electrolysers, green ammonia, and value-added downstream battery developments.

Australia-based startup buys collapsed battery maker Britishvolt

Only weeks after announcing its plan to build a lithium-ion battery gigafactory in Geelong, Australia-based startup Recharge Industries has bought collapsed battery maker Britishvolt – doubling its manufacturing ambitions. The takeover resuscitates Britishvolt’s gigafactory play in northern England, and means the little known startup now holds two significant battery making projects.

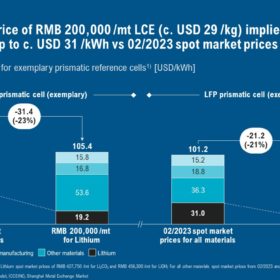

CATL offers big battery discounts amid looming lithium surplus

CATL’s new lithium pricing structure gives Chinese original equipment manufacturers (OEM) an effective discount of more than 20%. It is making the move to win more orders amid a slowdown in the electric-vehicle market and the ongoing efforts of cell manufacturers to secure raw materials.

Weekend Read: All of the above

Competition is intensifying in the electrolyser space. With the International Energy Agency (IEA) expecting 380 GW of hydrogen production capacity in 2030, four different technologies will likely become prominent as demand spikes. We take a look at the market.

GMG wins regulatory approval for battery manufacturing plant

Australian clean tech company Graphene Manufacturing Group plans to scale up the development of its battery energy storage technology that it claims charges 70 times faster than a lithium-ion battery and has three times more battery life.