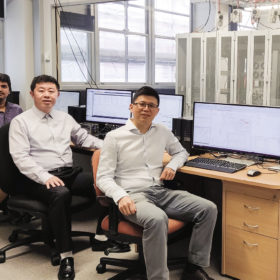

UNSW researchers develop high yield, low cost, eco-friendly process to recycle Si-PV modules

A team of researchers from the University of New South Wales (UNSW) has proposed a cost-effective way to recycle silicon solar panels. Their process consists of module deframing, laminate shredding and material concentration using electrostatic separation, reducing their original weight by 2% to 3%.

NSW payments for hosting new transmission lines set to double

As it looks to replace its ageing coal-fired fleet and accommodate a growing share of renewables on its grid, New South Wales has pledged to nearly double the average payments landlords across the state receive for hosting high voltage transmission lines.

Non-flammable, graphene-based lithium-ion batteries approaching stationary storage market

US-based Nanotech Energy’s graphene battery uses proprietary electrodes with a thermally stable separator, and non-flammable electrolyte that is said to be inexpensive to manufacture. The technology is said to be superior in terms of safety and competitive in terms of cell performance.

Thermal batteries to power gas-plant steam turbines subject of $1 million feasibility study

In a project where the old world of energy meets the new, AGL will investigate the technical and financial feasibility of using thermal batteries to provide the steam for a 200 MW turbine at South Australia’s Torrens Island Power Plant, which usually run on gas.

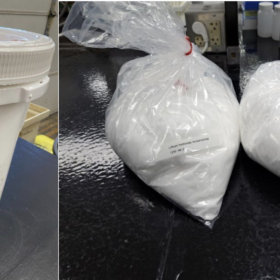

Australian company’s novel green lithium concept yields battery-grade product in Germany

ASX-listed Vulcan Energy, a company working on a project in Germany that it says will deliver ‘zero carbon’ lithium by combining geothermal plants with lithium electrolysis, today announced its pilot produced high grade lithium hydroxide which ‘easily exceeds’ battery grade specification.

Solar at night

Director of the Australian Solar Thermal Research Institute, Dominic Zaal, offers a deep dive into the capabilities of concentrated solar thermal technology, including what has been proven by global projects so far and how the all important Power Purchasing Agreements stack up.

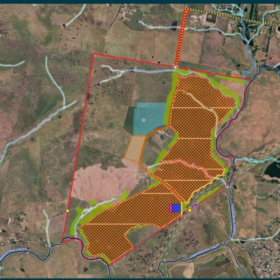

Underground heat exchanger to cool down solar panels

Spanish scientists have built a cooling system featuring heat exchangers on solar panels and U-shape heat exchangers installed in a borehole at a depth of 15 meters. The researchers claim that this reduces panel temperatures by up to 17%, while improving performance by about 11%.

Weekend read: In the testing loop

In northern Australia, a new hardware-in-the-loop platform is being developed to test renewable projects aggregated generation control systems before commissioning. The platform brings control hardware together with software simulations of passive components to test in real time how different configurations respond. Should the platform successfully complete its upcoming demonstration, it could help solve Australia’s current connection crisis.

Volt unveils ‘world beating’ Australian-engineered solar tile

Melbourne-based renewable energy company Leeson Group has unveiled an Australian-engineered roof solar PV tile that it describes as the highest energy generating solar tile in the world, with a solar efficiency of up to 19.3%.

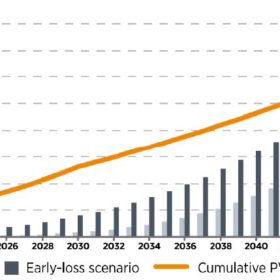

New tool to simulate climate at utility-scale PV project sites

Scientists in China have designed a new methodology to simulate the near-surface climate of utility-scale PV plants. Their findings suggest that the new tool could be used to design more climate-friendly solar parks.