Global PV investment to surpass $765 billion in 2024

The International Energy Agency projects that solar will attract more investment than all other electricity generation sources combined. Global energy spending is set to surpass $4.59 trillion (USD 3 trillion) for the first time this year.

Versatile lithium-ion can unpick gridlock

The Swiss Army knife qualities of lithium-ion batteries have helped scale the technology. Now their ubiquitous nature means they are ideally placed to help electricity system operators balance the grid, argues Gerard Reid, co-founder and partner of Alexa Capital.

PV module cooling tech tipped to boost net electrical energy

Scientists in Europe have created an after-market cooling solution that can be fitted to existing standard PV modules. The system is based on a water chamber placed at the backside of the module and can reportedly provide a net electrical energy gain of more than 9%.

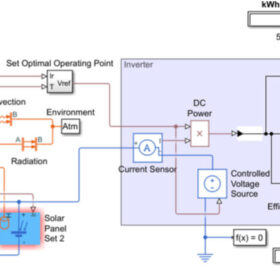

New model to identify optimal power sizing ratio for solar inverters

Researchers in Malaysia have proposed a new approach to identify the optimal power sizing ratio to balance PV energy capture with inverter costs. The calibrated model is said to accurately reflect the relationship between inverter efficiency and real-world system behavior.

WoodMac says global solar tracker shipments grew by 28% in 2023

Global tracker shipments reached 92 GWdc last year, according to WoodMackenzies’ latest report, with three United States-based manufacturers, Nextracker, Array Technologies and GameChange Solar, ranking as the three largest shippers in the world.

Long-term look at albedo tipped to pay off over project lifetime

As bifacial modules proliferate, estimations of albedo are becoming more important and with developers not prepared to install weather stations to assess solar resource, a popular option has become third-party, on-site measurements over periods as short as a day. Is this an acceptable compromise between costly on-site measuring and less accurate satellite data? Everoze’s Stefan Mau discusses the potential benefits and limitations of this approach.

Sinovoltaics shuffles PV module manufacturer financial stability rankings

The third edition of the Sinovoltaics financial stability report ranking lists India-based Abhishek Corp, Insolartion Energy, Waaree Renewable Technologies, and Solex Energy, all based in India, followed by United States-headquartered First Solar as the top five. Six additional manufacturers entered the global ranking.

How long do residential solar batteries last?

Multiple factors affect lifespan of a residential battery energy storage system. We examine the life of batteries in Part 3 of our series.

China’s solar dominance not an issue

In a new monthly column for pv magazine, the International Solar Energy Society (ISES) explains why potential trade disruptions in the global PV supply chain are substantially different from those related to coal, oil and gas.

How long do residential solar inverters last?

Multiple factors affect the productive lifespan of a residential solar inverter. In Part 2 of our series, we look at solar inverters.