The initial findings support the rapid development in both the business case and technical solution for the $2 billion lithium-ion battery factory in Townsville, according to an update released by Magnis Energy, Australia’s graphite miner and one of the three members of the Imperium3 consortium.

The study confirms the suitability of Townsville in large-scale battery manufacturing because of its proximity to booming Asian EV and renewable energy markets, logistics, local availability of raw materials such as lithium and manganese, skilled workforce and Townsville’s ambition to become the centre of high technology manufacturing with an emphasis on sustainability.

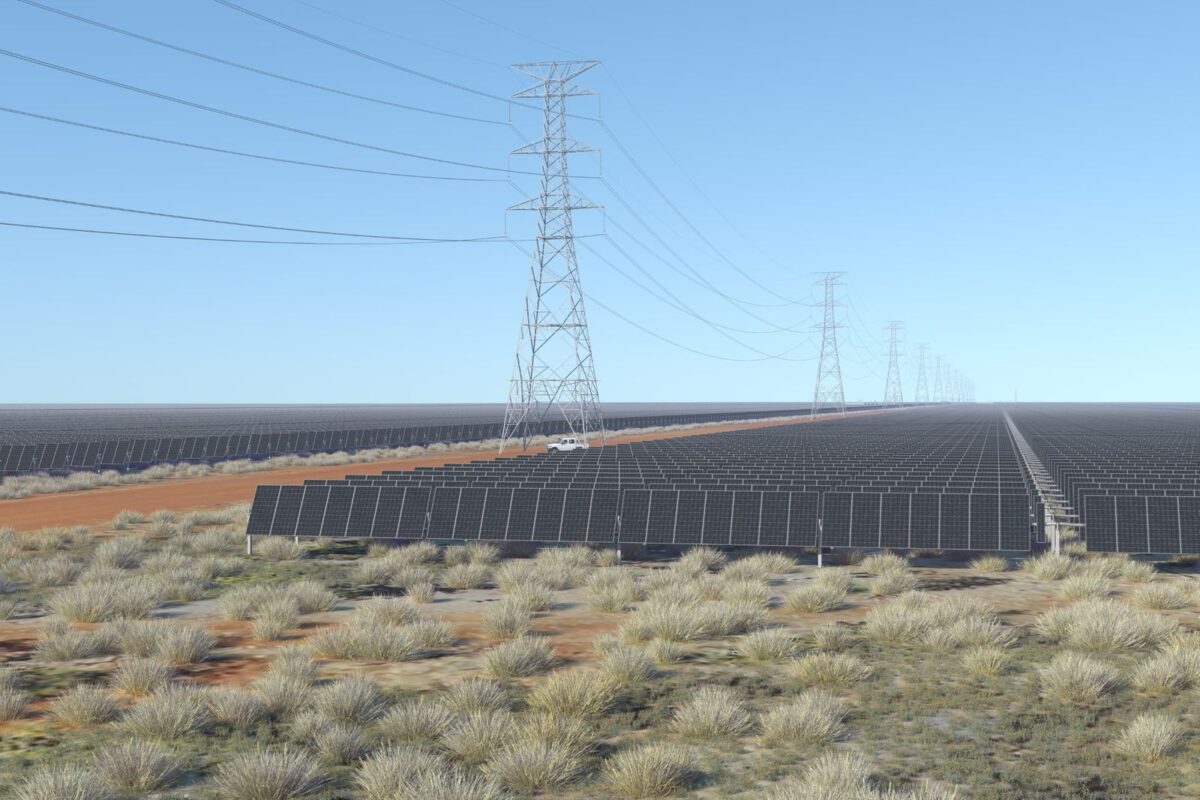

The business case for the 15 GWh LIB manufacturing facility at Townsville continues to grow in strength. The update notes that the positive developments driving the case include strong electrification of mobility and the transition to renewables, as well as rapidly falling costs, with solar and wind technologies as the cheapest way to generate electricity in Australia, compared to any other new-build technology. The falling costs have spurred growing government support, Magnis notes.

The Imperium3 Townsville consortium, which consists of Magnis Energy Technologies Ltd, C4V LLC New York and Boston Enerygy and Innovation, predicts the plant will further develop Queensland’s advanced manufacturing capabilities. A scooping study has established local content opportunities to be in the order of $300 million across a range of items including labour, power, fuel, security and logistics.

With the plant expected to create approximately 750 jobs in high technology manufacturing, the consortium is investigating and identifying future participation of local businesses in both the construction and operating phases of the project. The technical solution is being delivered by local engineering specialists, in particular Brisbane-based Ausenco, which is overseeing process development and the GHD office in Townsville, which is overseeing site development and building design.

In terms of downstream opportunities, an additional potential economic gain to the local economy is expected to amount from US$750 million to US$1.5 billion annually.

“In recent times we have been approached by members from both major parties federally and prominent business leaders in our community who are interested in assisting and being involved in the project which is very encouraging,” said Imperium3 Chairman Shailesh Upreti.

The feasibility study was underpinned by the Queensland government, which provided $3.1 million towards the project last year. Minister for State Development, Manufacturing, Infrastructure and Planning Cameron Dick stated at the time that the study is a key requirement for attracting the next stage of funding and is expected to be completed in 2019. “We expect Imperium3 will make the final investment decision by mid-2020,” he said.

In addition to the Townsville plant, the consortium is developing another “gigafactory“ – a 15 GWh plant in New York, which is expected to commence production this year. Meanwhile, Magnis is also involved in the development of a 30 GWh factory and recycling plant in North Rhine Westfalia, Germany and engaged in talks to build a 1 GWh production capacity LIB plant in India that would eventually be scaled up to 30 GWh.

The factories aim to produce next generation li-ion technology, which provide significant cost reductions without sacrificing voltage, capacity or cell energy. With cathodes free from both cobalt and nickel, Magnis has pledged to responsibly source the raw materials, associated technologies and components for the LIB cells.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.