A group of scientists – led by UNSW and in collaboration with the University of Sydney – are claiming a world first in the global race to develop durable perovskite solar cells, often called “the next generation” of solar PV technology. In a major step towards commercialization, the group has announced its perovskites have passed strict International Electrotechnical Commission testing standards for heat and humidity.

The scientists have worked with metal halide perovskite solar cells, which have undergone unprecedented progress with their power conversion efficiencies increasing from 3.8 % to 25.2 % in merely 10 years. For the sake of comparison, it took about 40 years for scientists to develop silicon-cell conversion rates of 26.7%. “They are very inexpensive, 500 times thinner than silicon and are therefore flexible and ultra-lightweight. They also have tremendous energy enabling properties and high solar conversion rates,” said Professor Anita Ho-Baillie, the inaugural John Hooke Chair of Nanoscience at the University of Sydney.

However, unprotected perovskite cells do not have the durability of silicon-based cells, so they are not yet commercially viable. To step out of the lab, perovskites need to endure long term environmental stresses imposed by moisture, heat, and light. “Perovskite cells will need to stack up against the current commercial standards. That’s what is so exciting about our research. We have shown that we can drastically improve their thermal stability,” Professor Ho-Baillie said.

Simple glass and polymer as a fix

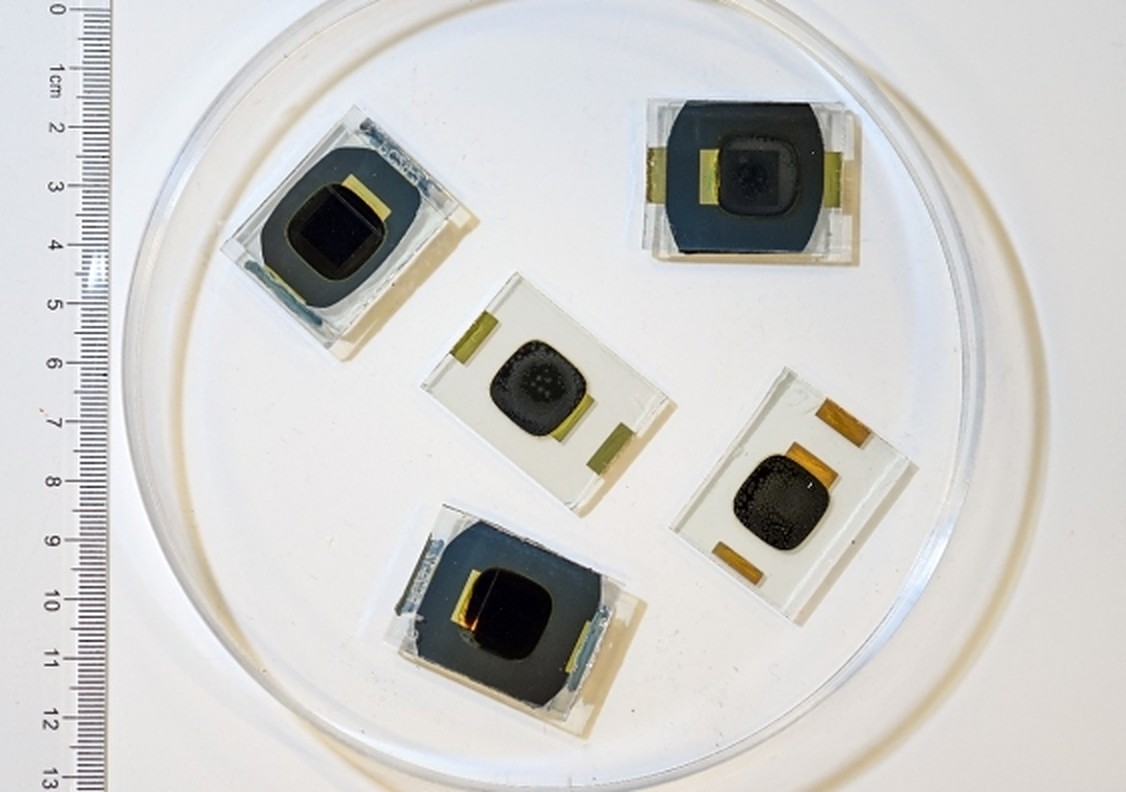

The research, authored by 14 scientists mostly based in Australia and published today in the journal Science, details the low-cost solution the team came up with. The researchers used gas chromatography-mass spectrometry (GC-MS) to identify the signature volatile products and decomposition pathways of the thermally stressed hybrid perovskites commonly used in high-performance cells. Using this method, they found that that organic-inorganic perovskite solar cells encapsulated with simple and low-cost polyisobutylene (synthetic rubber)-based or polyolefin-based polymer – glass combination have excellent durability exceeding the requirements of the IEC61215:2016 Damp Heat and Humidity Freeze tests.

The researchers were able to confirm that low-cost polymer-glass stack pressure-tight encapsulation is effective in suppressing the perovskite ‘outgassing’, the process that leads to its decomposition. Using such an encapsulation scheme, CH3NH3 (MA) containing multi-cation multihalide perovskite solar cells survived more than 1800 hours of Damp Heat test and 75 cycles of 30 Humidity Freeze test exceeding the requirement of IEC61215:2016 standard for the first time, far outperforming the team’s expectations.

“Another exciting outcome of our research is that we are able to stabilise perovskite cells under the harsh International Electrotechnical Commission standard environmental testing conditions. Not only did the cells pass the thermal cycling tests, they exceeded the demanding requirements of damp-heat and humidity-freeze tests as well,” Professor Ho-Baillie said.

These tests help determine if solar cell modules can withstand the effects of outdoor operating conditions by exposing them to repeated temperature cycling between -40 degrees and 85 degrees, as well as exposure to 85% relative humidity.”These results are especially significant because the perovskite solar cells used in this study contain MA cations which are known to have lower thermal stability. Yet, these cells survived the Humidity Freeze test which exerts the harshest humid and thermal stress,” the research paper concludes.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

What I find intriguing is the possibility of making tandem solar PV cells using well known and established crystalline silicon technology, which in its own right can be found in 22% to 24% solar harvest efficiency today off of many manufacturing lines. By taking something like TOPCon N panel technology and spraying on the perovskite and ‘sealant’ could make the 35% maybe even more efficient solar PV cell that would last 30 years or more. The possibility of up to 40% solar harvest, cheap fast manufacturing to “stack” the two technologies, would be the next game changer in the solar PV field. Imagine with a home’s roof having a 400 square foot or about 37 square meters of space, the solar panel would go from an average of 7.26kWp to 14.78kWp in the same roof space. Got twice the amount of space on one’s roof? At 40% efficiency, that’s right at 29.6kWp, using just 3 hours of this amount of generation, one could store this energy and run the house at night also.

I say, bring it on.