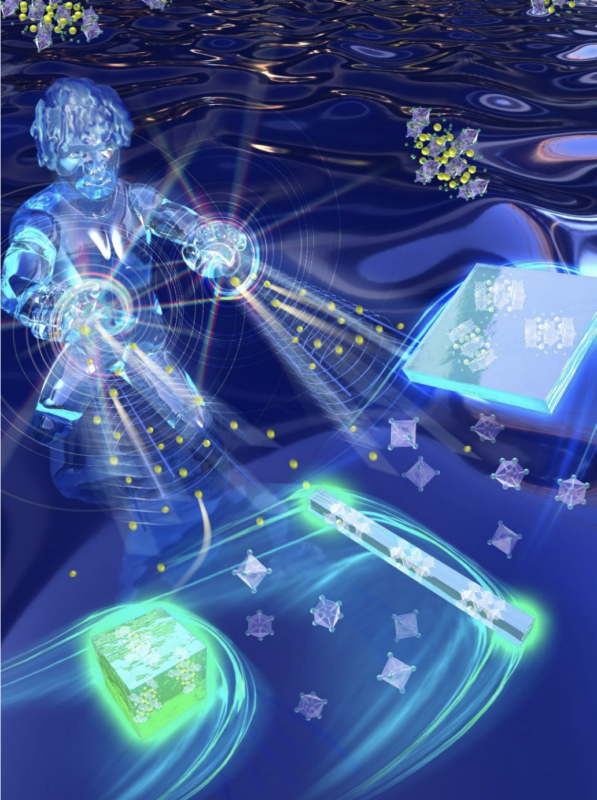

Researchers from Melbourne’s Monash University have discovered water can be used as the key ingredient in the precursor solution which helps fabricate perovskites to their exact specifications.

Perovskites are a nanomaterial with a crystal structure which hold potential for the next generation of photovoltaics, semiconductors and LEDs. Perovskites have already shown similar efficiencies to silicon, are cheaper to make, and feature a tuneable bandgap, meaning the energy they are able to absorb, reflect or conduct can be changed to suit different purposes.

Perovskites, however, are infamously prone to defects – something which researchers like those at the ARC Centre of Excellence in Exciton Science are seeking to solve.

Ordinarily, water is kept as far away as possible during the process of creating perovskites since the presence of moisture can lead to defects in the materials, causing them to fall apart more quickly when they’re being used in a device. Hence perovskites in scientific research are often made via spin coating in the sealed environment of a nitrogen glove box.

Now, though, the Monash-led team have found a simple way to control the growth of perovskite crystals by harnessing water as a positive factor. This liquid-based mechanism works at room temperature, so the approach remains cost effective.

Exciton Science

The team found that by changing the ratio of water to solvent during the early stages of the process, they could choose to grow different types of perovskite crystals, with structures to suit various purposes.

“By carefully tuning the concentration of water in the precursor solution, we realised the precise control of particular perovskite phases,” Dr Wenxin Mao of Monash University. The findings from Dr Wenxin and his team have been published in the journal Advanced Functional Materials.

Computational and thermodynamic analysis conducted by colleagues at the University of Sydney identified that the coordination of lead and bromide ions in the precursor solution was an important factor in determining which types of crystals are formed.

“We now understand the internal mechanics and function of water inside the precursor solution. By doing that we can further use water to control the crystallisation process,” lead author Qingdong Lin, a PhD student at Monash University, said.

To demonstrate the quality of the end product, crystals produced via this approach were coupled with back-contact electrodes through nanofabrication to create X-ray detection devices.

This test sample performed at a similar level to commercial X-ray detectors currently being used in real-world settings, the researchers said, and out-performed prototype perovskite X-ray detectors developed using slower, more complicated fabrication methods.

“We compared them with commercial X-ray detectors as well as other types of perovskites and we do have a very good responsivity and sensitivity to X-rays. Overall this project shows that we have found a smart way to control inorganic perovskite single crystals,” Dr Wenxin said. “The methodology is flexible and feasible and doesn’t require a very unique environment or technique to apply it.”

As well as solar cells, X-ray detectors and LEDs, perovskites created with this method may also be useful in UV light detection, lasers and solar concentrators.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.