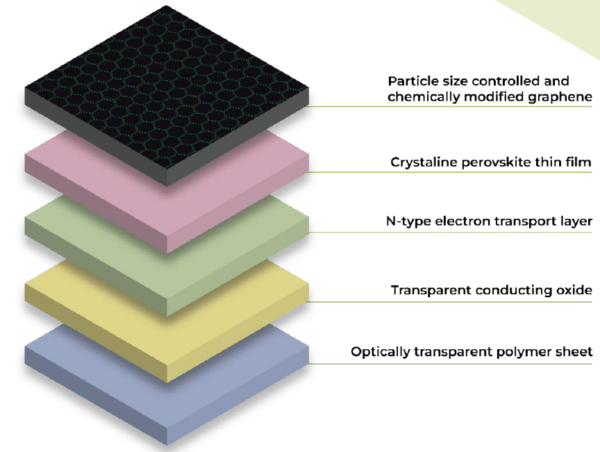

Western Australia-headquartered graphene manufacturer First Graphene has joined forces with NSW-based perovskite cell producer Halocell Energy to supply graphene for the commercial production of Halocell’s perovskite indoor solar cell module.

Supplying its proprietary PureGraph product for use as a high-performing coating for the perovskite solar cells enables Halocell Energy to expedite its manufacturing process and enhance light absorbing performance.

Graphene enhanced modules are up to five times more efficient than conventional silicon solar cells and are more cost-effective, with Halocell Energy demonstrating graphene can reduce manufacturing and materials costs by over 80% as the need for high-cost conductor materials such as gold and silver are eliminated.

The graphene formulations will also allow the use of roll-to-roll dispersion, which is a rapid, scalable, and low-cost production technique used to create the perovskite solar cells.

First Graphene

First Graphene Managing Director and Chief Executive Officer Michael Bell said the agreement with Halocell Energy is a significant milestone for the company as it officially enters the commercial perovskite solar cell industry.

“These locally manufactured products will change the way Australians leverage solar power in their home and improve Australia’s renewable energy performance as a whole,” Bell said.

“Importantly, the agreement opens a door further for First Graphene to showcase the benefits of leveraging the unique properties of graphene to improve renewable energy technology.”

Halocell Energy Chief Executive Officer Paul Moonie said the manufacturing supply agreement is pivotal and marks a significant step forward for Halocell in developing cutting-edge perovskite solar cells.

“By leveraging First Graphene’s advanced graphene formulations, we can optimise particle size and surface chemistry, enhancing the efficiency and scalability of our solar cells,” Moonie said.

“The integration of these locally supplied materials into our roll-to-roll production process enables cost-effective, rapid manufacturing, which will be a gamechanger for the solar industry in Australia,” Moonie said.

The roll-to-roll technique is also the subject of research and development work conducted in collaboration between First Graphene, Halocell Energy and Queensland University of Technology (QUT).

In September 2023, the three organisations received $2 million (USD 1.3 million) in funding from the Australian government to support a three-year project investigating commercialisation of the renewable energy technology.

The global perovskite solar cell market has been valued at more than $95 million, with demand expected to nearly double the market value over the next year. In Australia, energy generated by solar cells accounts for more than 11% of the nation’s total energy supply.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.