From pv magazine

Researchers from the University of New South Wales (UNSW) and Chinese-Canadian PV module maker Canadian Solar have investigated the effect of soldering flux on both TOPCon and heterojunction (HJT) solar cells and have ascertained that the choice of this component is key to avoiding potential module failures.

“Our study directly addresses a critical issue: the sensitivity of HJT solar cells to soldering flux-induced degradation, particularly in metallisation and the ITO layer,” the research’s lead author, Bram Hoex, told pv magazine.

“We identified that pre-existing pores in the silver metallisation allow flux penetration, triggering chemical reactions that degrade contact integrity.”

Hoex also explained that, by conducting cell-level experiments instead of module-level testing, the research team could accelerate the failure analysis process by up to two orders of magnitude, enabling rapid identification of degradation mechanisms.

“This approach provides faster insights into material compatibility and reliability, significantly enhancing the efficiency of research and industrial evaluation of soldering fluxes for HJT cells,” he added.

Image: University of New South Wales, Progress in Photovoltaics, CC BY 4.0

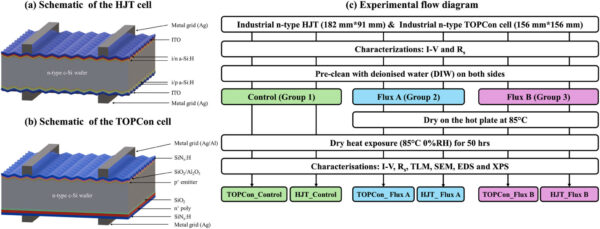

The scientists analyzed the effect of soldering flux on half-cut bifacial n-type silicon HJT cells measuring 182 mm × 91 mm and bifacial n-type TOPCon solar cells with a size of 156 mm × 156 mm, with both cell types being sourced from commercial production lines and being processed with two types of commercial soldering flux dubbed Flux A and Flux B.

“Flux A is a halide-free soldering flux, meaning it does not contain halogen-derived ions, whereas Flux B is a halogen-free soldering flux, which excludes elements from the halogen group,” the scientists explained.

“Both fluxes were heated up to 120 C to ensure complete evaporation of the alcohol.”

They divided the analyzed cells into three groups: A control group with two TOPCon cells and two HJT cells that were not exposed to any soldering flux; the Flux A group including two TOPCon cells and two HJT cells that were treated with Flux A on both surfaces; and the Flux B group comprising two TOPCon cells and two HJT cells that were treated with Flux B on both surfaces.

The analysis showed that the TOPCon cells remained stable under dry heat testing at 85 C with no degradation, while the HJT cells showed severe degradation, with power losses of around 61% rel with Flux A and about 55% rel with Flux B after 50 hours.

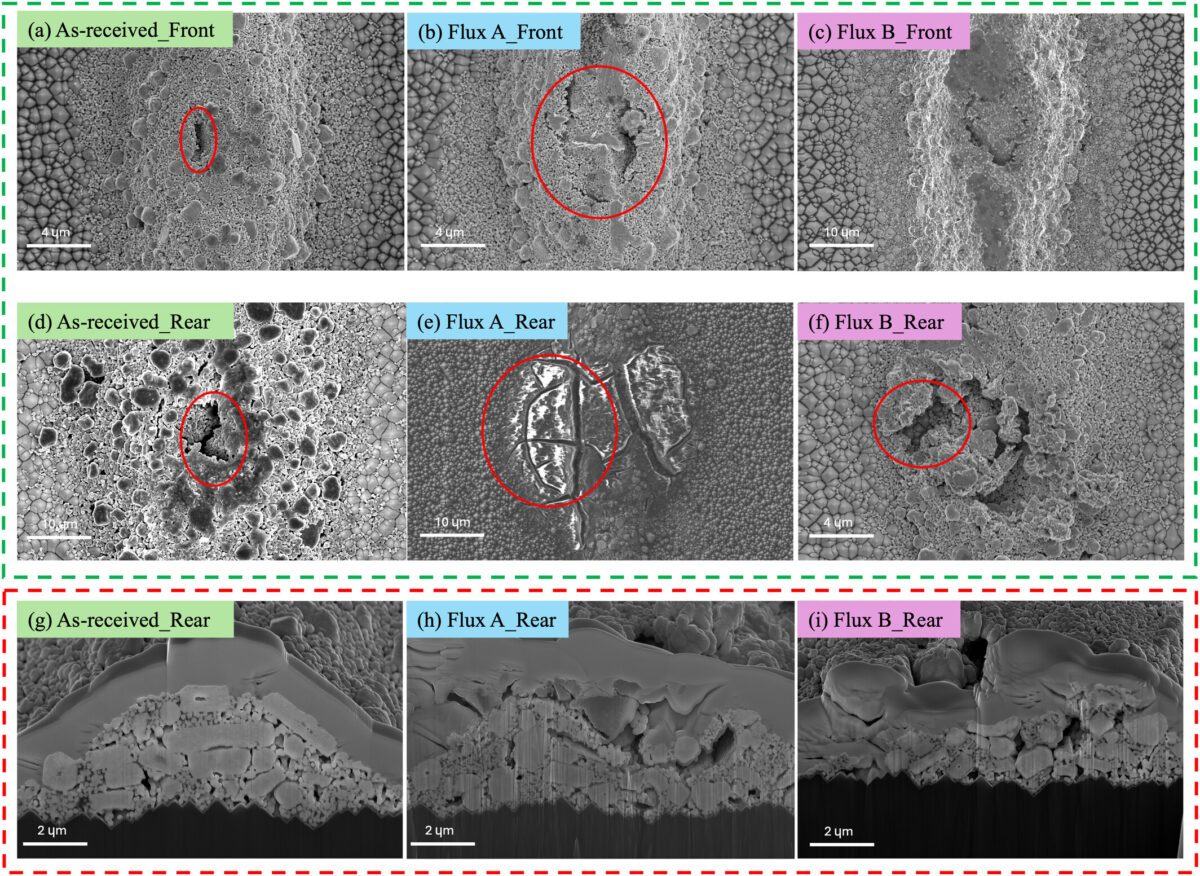

The power losses in the HJT cells were found to be caused by holes in the metallisation layer, which facilitates soldering flux penetration, leading to chemical reactions that degrade performance. Furthermore, it was ascertained that the indium tin oxide (ITO) layer in HJT cells is highly susceptible to damage from soldering flux.

“The primary driver of this degradation was an increase in contact resistivity on both the front and rear surfaces, resulting in a pronounced rise in series resistance,” the academics emphasised.

“This increased series resistance arose from considerable damage/corrosion to the ITO layers and metal contacts, most notably in the form of peeling in some ITO regions and cracking in the metal electrodes. Pre-existing pores or holes in the metal electrode likely allowed the soldering flux to penetrate and chemically react with Ag particles and binder resin, exacerbating the cracking after dry heat exposure.”

The research team concluded that HJT solar cells are vulnerable to soldering flux degradation even in encapsulated modules with low water vapor transmission materials.

“Careful selection of soldering flux is crucial to prevent long-term performance losses in HJT modules,” Hoex said.

“Supplier datasheets may lack critical information on flux composition and potential impact. Independent component analysis is strongly recommended before large-scale manufacturing.”

The analysis was described in “The Influence of Soldering Flux on Stability of Heterojunction and TOPCon Solar Cells,” which was recently published in Progress in Photovoltaics.

This work builds on some of UNSW’s previous work, including a study showing the vulnerability of TOPCon solar cells to contact corrosion, research identifying three TOPCon panel failure types that are absent in PERC products, and a work assessing the impact of sodium-induced degradation in heterojunction solar cells under accelerated damp-heat testing, among others.

Caption to main photograph:

Top-view SEM images of front contact of (a) as-received HJT solar cell, (b) HJT solar cell exposed to Flux A and (c) HJT solar cell exposed to Flux B and rear contact of (d) as-received HJT solar cell; (e) HJT solar cell exposed to Flux A and (f) HJT solar cell exposed to Flux B. Cross-sectional SEM images of rear contact of (g) as-received HJT solar cell, (h) HJT solar cell exposed to Flux A and (i) HJT solar cell exposed to Flux B. Please note that all samples exposed to flux also were annealed at 85°C and 0% RH for 50 h.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.