Floating solar, battery manufacturing co-op among nine projects funded in coal country Victoria

The Victorian government will fund a floating solar project, an initiative to locally manufacture solar batteries, and install a portable renewable energy system for community services during emergencies as part of its Latrobe Valley program.

Fully PV-driven system to produce water, electricity, crops

Researchers in Saudi Arabia have fabricated an integrated fully PV-powered system to extract fresh water from the atmosphere. The system uses excess heat from the solar modules to evaporate and condense water that can then be used to grow crops. Part of the water is also used to cool down the solar modules through an active cooling technique.

‘The major solar players will shift from PERC to TOPCon’

US analyst Clean Energy Associates made some notable predictions in its Q4 survey of the world solar manufacturing market, including echoing predictions made elsewhere that the new polysilicon production capacity coming online now will help arrest the spike in solar panel prices.

Nomadic knocks over 2MW solar install in less than 21 days

The merits of pre-assembled and modular solar solutions have been showcased by independent power provider Nomadic Energy which this week revealed it had taken less than 21 days to complete a 2MW install at Northern Star Resources’ Carosue Dam gold mining operation near Kalgoorlie in Western Australia.

World’s largest electrolyser fab breaks ground in Australia

Fortescue Future Industries says the first electrolysers to be manufactured at the facility, early next year, are earmarked for use in Queensland at FFI’s planned green-hydrogen-to-ammonia project on Gibson Island.

Origin plans hydrogen hub in place of its soon-to-be-closing coal assets

Origin Energy has announced plans for a potential Hunter Valley Hydrogen Hub underpinned by a deal it’s made with mining and infrastructure company Orica.

Building a sustainable, vertically integrated solar manufacturing ecosystem in India

A new report by JMK Research and IEEFA says Indian solar manufacturers need to create a strong foundation for sustainable development overall by integrating raw materials and impetus to R&D in their plans, rather than focusing solely on output.

Aussie researchers find best BIPV envelope design alternatives

Scientists in Australia have developed an optimisation framework for building-integrated photovoltaics that allows the selection of design variables according to user preferences. Their model considers PV-related features such as tilt angle, window-to-wall ratio (WWR), PV placement, and PV product type, as well as objective functions and constraints such as the net present value and the payback period.

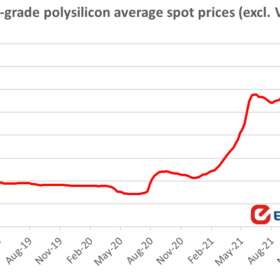

Polysilicon price fluctuations expected to continue until late 2023

Two industry experts have provided analyses of the current polysilicon price scenario in a chat with pv magazine and both agreed that polysilicon demand is still growing faster than supply. The price may decrease starting from the second quarter and reach more reasonable levels by the end of the year.

Weekend read: Silicon carbide’s second coming

Silicon carbide (SiC) has promised inverter makers higher power density, higher efficiency, and a total bill of materials that comes in closer to its more established rival in silicon. Has SiC finally arrived? Tristan Rayner spoke to the people at the forefront of the wider-bandgap material to find out the back story and what’s next.