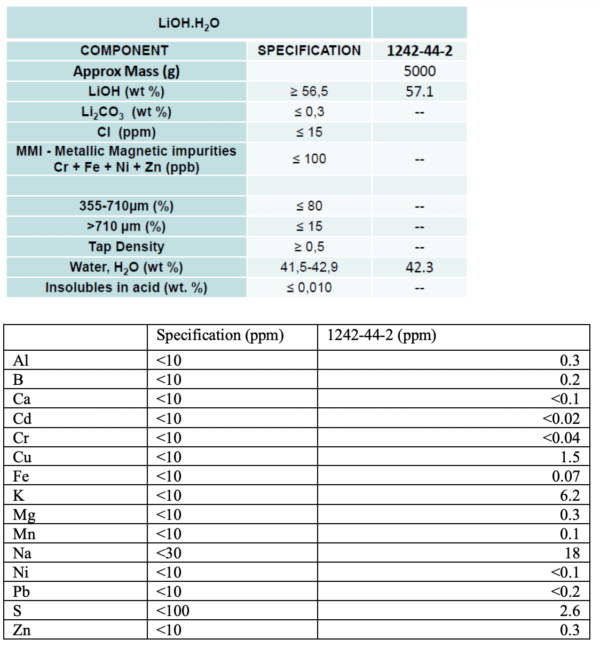

Vulcan Energy, technically an Australian company though its projects and staff are largely concentrated in Germany, announced its pilot project produced lithium hydroxide graded at 57.1%, exceeding the battery grade specification of 56.5% required from offtake customers.

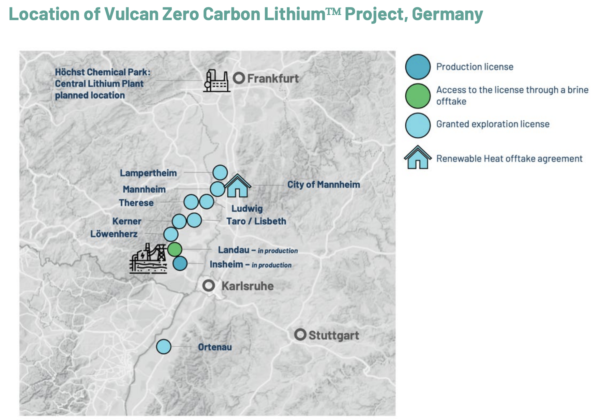

Vulcan is currently working on its pilot project in Germany’s Upper Rhine Valley, one of Europe’s best geothermal resources.

The company’s concept for producing ‘zero carbon’ lithium is to use well established geothermal energy technologies to extract the Upper Rhine’s lithium-rich brine and then use the more novel technique of lithium electrolysis to create the final lithium hydroxide product.

Vulcan Energy Resources

Lithium – by far the globe’s most popular energy storage material – exists in an uncomfortable position where the act of getting it poorly impacts the environment. But the promise of Vulcan’s ‘green lithium’ extraction has seen the company already close deals with big automakers. Eager to secure supplies for the transition from petrol to electric vehicles, in June 2022, Stellantis, which owns brands like Peugeot, Citroen, Fiat, Chrysler and Opel, announced a $76 million (USD 47.8 million) equity investment in Vulcan. Vulcan also has offtake agreements with the likes of LG Energy Solution, Volkswagen, Reno, and Belgian battery cathode specialist Umicore.

In terms of how the company actually produced this latest batch of high grade, low impurity lithium hydroxide, Vulcan says lithium chloride was extracted by sorbent in its pilot plant, recovered with water and sent offsite “where it was purified and concentrated by a third-party provider to prepare the lithium chloride for electrolysis to produce lithium hydroxide solution. The solution was then crystallised to produce battery grade lithium hydroxide monohydrate.”

“The embodied renewable heat within our brine means we are able to leverage sorption, a commercially proven process to extract lithium from brines that requires heat to work,” Vulcan’s Managing Director and CEO Francis Wedin explained. “Sorption is highly selective, which means that we can produce a very pure LiCl [lithium chloride] eluate. This in turn means we are able to use lithium electrolysis, a method of producing lithium hydroxide directly which by its nature produces a very pure product, in excess of the purity required for use in electric vehicle batteries, with minimal reagent usage.”

Image: Vulcan Energy Resources

Vulcan’s pilot plant in Germany has been operating since April 2021, with the company now announcing it has sufficient data to complete the first phase of its definitive feasibility study, scheduled for early next year.

It is also began works on its containerised sorption demonstration plant in Germany. The plan is for the demonstration plant to serve as a facility to train Vulcan’s operations team in a pre-commercial setting, prior to commercial production targeted for 2025.

This content is protected by copyright and may not be reused. If you want to cooperate with us and would like to reuse some of our content, please contact: editors@pv-magazine.com.

5 comments

By submitting this form you agree to pv magazine using your data for the purposes of publishing your comment.

Your personal data will only be disclosed or otherwise transmitted to third parties for the purposes of spam filtering or if this is necessary for technical maintenance of the website. Any other transfer to third parties will not take place unless this is justified on the basis of applicable data protection regulations or if pv magazine is legally obliged to do so.

You may revoke this consent at any time with effect for the future, in which case your personal data will be deleted immediately. Otherwise, your data will be deleted if pv magazine has processed your request or the purpose of data storage is fulfilled.

Further information on data privacy can be found in our Data Protection Policy.